Fuel injector issues can significantly impact engine performance and driveability. CAR-CODING.EDU.VN offers expert remote car coding assistance to diagnose and resolve these problems effectively. Our services include ECU programming, hidden feature activation, and permanent fault code clearing. We specialize in remote automotive coding support, ensuring your vehicle runs optimally.

1. What Are Vcds Fuel Trim Measuring Blocks and Why Are They Important?

VCDS fuel trim measuring blocks are diagnostic tools used with the VCDS (VAG-COM Diagnostic System) software to monitor and analyze the fuel trim values in a vehicle’s engine. These blocks provide critical data for assessing the performance and health of the engine’s fuel delivery system.

-

Fuel Trim Defined: Fuel trim refers to the adjustments made by the engine control unit (ECU) to regulate the air-fuel mixture. The ECU adjusts the amount of fuel injected into the engine cylinders to maintain an optimal air-fuel ratio (typically 14.7:1 for gasoline engines).

-

Short-Term Fuel Trim (STFT): This is a dynamic adjustment made by the ECU in real-time to respond to immediate changes in engine operating conditions. STFT values fluctuate rapidly as the ECU fine-tunes the fuel mixture based on sensor inputs like the oxygen sensors.

-

Long-Term Fuel Trim (LTFT): This represents a more permanent correction applied by the ECU over time. LTFT values are learned by the ECU based on the average adjustments made by the STFT. If the STFT consistently deviates in one direction, the ECU will adjust the LTFT to compensate.

-

VCDS Measuring Blocks: VCDS allows you to view the STFT and LTFT values through specific measuring blocks. Block 032 is commonly used to view the LTFT at idle and under partial load, while Block 033 displays the STFT values.

-

Importance of Monitoring: Monitoring fuel trim values is essential for diagnosing various engine problems, including:

- Vacuum Leaks: A vacuum leak can cause a lean condition, leading to positive fuel trim values.

- Faulty Oxygen Sensors: Inaccurate readings from oxygen sensors can result in incorrect fuel trim adjustments.

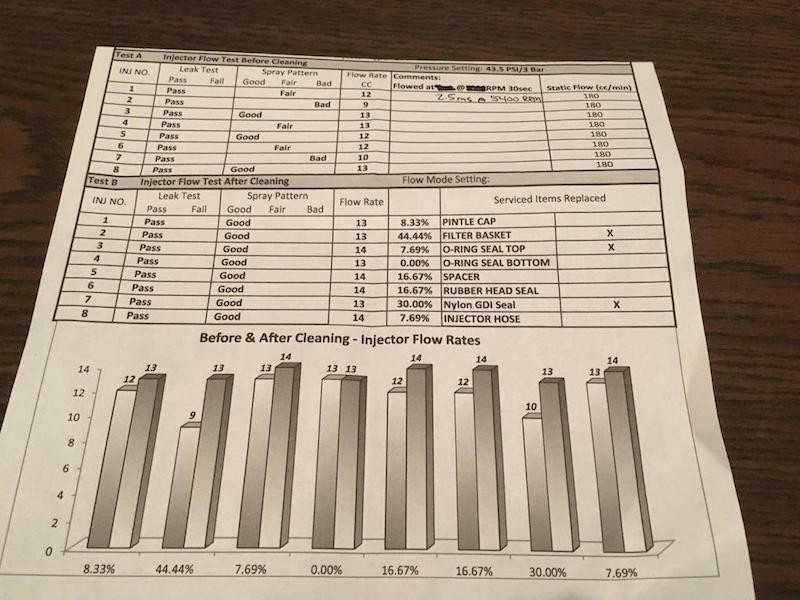

- Fuel Injector Issues: Clogged or malfunctioning fuel injectors can disrupt the fuel delivery, affecting fuel trim values.

- Mass Airflow (MAF) Sensor Problems: A faulty MAF sensor can provide incorrect airflow data, leading to fuel trim errors.

- Exhaust Leaks: Exhaust leaks near the oxygen sensors can introduce extra air, causing the ECU to compensate with fuel trim adjustments.

2. How Do I Access and Interpret VCDS Fuel Trim Data for Accurate Diagnosis?

Accessing and interpreting VCDS fuel trim data involves connecting a VCDS interface to your vehicle, navigating to the appropriate measuring blocks, and analyzing the displayed values to diagnose potential issues.

-

Connecting VCDS:

- Plug the VCDS interface into the OBD-II port of your vehicle.

- Start the VCDS software on your computer.

- Select the appropriate control module (e.g., engine control module).

-

Navigating to Measuring Blocks:

- Go to the “Measuring Blocks” or “Advanced Measuring Values” function.

- Enter the measuring block number for fuel trim data (e.g., 032 for LTFT, 033 for STFT).

- View the displayed values for each parameter.

Interpreting Fuel Trim Values:

* **Normal Range:** Ideally, both STFT and LTFT values should be close to 0%. A range of +/- 10% is generally considered acceptable.

* **Positive Values:** Positive fuel trim values indicate that the ECU is adding fuel to compensate for a lean condition (too much air, not enough fuel).

* **Negative Values:** Negative fuel trim values indicate that the ECU is reducing fuel to compensate for a rich condition (too much fuel, not enough air).

* **High Positive Values (e.g., +10% or higher):** Suggest a significant lean condition, which could be due to vacuum leaks, faulty fuel injectors, or a failing MAF sensor.

* **High Negative Values (e.g., -10% or lower):** Suggest a significant rich condition, which could be due to excessive fuel pressure, leaking fuel injectors, or a faulty oxygen sensor.-

Analyzing Data for Diagnosis:

- Vacuum Leaks: If you see high positive LTFT values at idle that decrease under load, suspect a vacuum leak.

- Faulty Oxygen Sensors: Erratic or slow-changing STFT values, combined with incorrect LTFT adjustments, may indicate a faulty oxygen sensor.

- Fuel Injector Issues: High positive LTFT values, especially under load, can indicate clogged or malfunctioning fuel injectors.

- MAF Sensor Problems: If both STFT and LTFT are consistently high or low, the MAF sensor may be providing incorrect airflow data.

- Exhaust Leaks: Exhaust leaks near the oxygen sensors can cause fluctuating fuel trim values.

Example:

* If LTFT at idle is +8% and LTFT at load is +3%, you might have a small vacuum leak that is more pronounced at idle.

* If LTFT is consistently +15% at both idle and load, suspect a more significant issue like a faulty MAF sensor or fuel delivery problem. VCDS Fuel Trim Measuring Blocks

VCDS Fuel Trim Measuring Blocks

3. What Are the Symptoms of Clogged Fuel Injectors That VCDS Can Help Identify?

Clogged fuel injectors can cause a range of symptoms that affect engine performance and efficiency. VCDS can help identify these issues by monitoring fuel trim values and other relevant parameters.

-

Common Symptoms of Clogged Fuel Injectors:

- Surging Idle: The engine idle speed fluctuates erratically, causing the vehicle to vibrate or stall.

- Rough Cold Start: The engine struggles to start when cold, often requiring multiple attempts.

- Engine Misfire: One or more cylinders fail to fire correctly, leading to a rough-running engine and reduced power.

- Performance Loss: The vehicle accelerates slowly and lacks its usual power, especially under load.

- Increased Fuel Consumption: The engine consumes more fuel than usual, resulting in lower fuel economy.

- Engine Damage: In severe cases, a fully clogged or leaking injector can cause engine damage due to improper combustion.

- Check Engine Light: The malfunction indicator lamp (MIL) illuminates, indicating a problem with the engine management system.

-

How VCDS Helps Identify Clogged Fuel Injectors:

- Fuel Trim Data: VCDS can display fuel trim values, which are essential for diagnosing fuel injector issues. Clogged fuel injectors typically cause a lean condition, leading to positive long-term fuel trim (LTFT) values, especially under load.

- Misfire Detection: VCDS can identify misfires by monitoring the crankshaft position sensor and detecting irregularities in engine speed. Misfires can be caused by clogged fuel injectors that prevent proper combustion in one or more cylinders.

- Oxygen Sensor Readings: VCDS can display the readings from the oxygen sensors, which provide feedback on the air-fuel mixture. Clogged fuel injectors can cause the oxygen sensors to report a lean condition, prompting the ECU to add more fuel.

- Injector Activation: VCDS may have the capability to activate individual fuel injectors to test their functionality. This can help identify injectors that are not firing correctly or are delivering an insufficient amount of fuel.

Case Example:

* A vehicle exhibits a rough idle, experiences misfires, and has a positive LTFT of +8% at idle and +12% under load. Using VCDS, the technician monitors the misfire counters and identifies that cylinder 3 is misfiring consistently. The oxygen sensor readings also indicate a lean condition. Based on this data, the technician suspects a clogged fuel injector in cylinder 3 and proceeds to inspect and clean the injectors.4. What VCDS Measuring Blocks Are Most Relevant for Diagnosing Fuel Injector Problems?

Several VCDS measuring blocks are particularly useful for diagnosing fuel injector problems, providing data on fuel trim, oxygen sensor readings, and other relevant parameters.

-

Key VCDS Measuring Blocks for Fuel Injector Diagnosis:

- Block 032 (Long Term Fuel Trim): Displays the long-term fuel trim values at idle and under partial load. Positive values indicate a lean condition, while negative values indicate a rich condition. High positive values, especially under load, can suggest clogged fuel injectors.

- Block 033 (Short Term Fuel Trim): Displays the short-term fuel trim values, which fluctuate in real-time to adjust the air-fuel mixture. Erratic or consistently high/low STFT values can indicate a problem with the fuel delivery system.

- Block 001 (Engine RPM, Load, and Coolant Temperature): Provides basic engine operating parameters that can help correlate fuel trim values with engine conditions.

- Block 002 (Mass Airflow (MAF) Sensor Reading): Displays the airflow measured by the MAF sensor. Incorrect MAF readings can lead to fuel trim errors and affect fuel injector performance.

- Block 003 (Oxygen Sensor Readings): Displays the voltage output from the oxygen sensors, which provides feedback on the air-fuel mixture. Abnormal oxygen sensor readings can indicate fuel injector problems.

- Block 015 & 016 (Misfire Detection): These blocks show misfire counts for each cylinder. High misfire counts can be caused by clogged or malfunctioning fuel injectors.

- Block 103, 106, 140 (Fuel Pressure): These blocks are used to check fuel pressure on both fuel rails, it is very important to make sure fuel pump or fuel filter is working properly.

Example Scenarios:

* **Scenario 1:** High positive LTFT in Block 032, misfires in Block 015/016, and lean oxygen sensor readings in Block 003 suggest clogged fuel injectors.

* **Scenario 2:** Normal LTFT but erratic STFT in Block 033, along with abnormal MAF readings in Block 002, indicate a potential MAF sensor problem affecting fuel trim.5. How Can I Use VCDS to Check Fuel Injector Performance and Identify Imbalances?

VCDS can be used to check fuel injector performance and identify imbalances by monitoring fuel trim values, misfire counts, and conducting injector activation tests.

-

Methods to Check Fuel Injector Performance with VCDS:

- Fuel Trim Analysis:

- Monitor LTFT and STFT values in Blocks 032 and 033 to identify lean or rich conditions.

- Compare fuel trim values at idle and under load to detect variations in fuel delivery.

- Look for consistently high positive LTFT values, which may indicate clogged fuel injectors.

- Misfire Detection:

- Use Blocks 015 and 016 to monitor misfire counts for each cylinder.

- Identify cylinders with excessive misfires, which could be caused by faulty fuel injectors.

- Oxygen Sensor Readings:

- Check oxygen sensor voltages in Block 003 to assess the air-fuel mixture.

- Look for lean or rich indications that correlate with fuel trim values and misfire data.

- Injector Activation Test (If Available):

- Some VCDS versions offer an injector activation test that allows you to individually activate each fuel injector.

- Listen for the distinct clicking sound of each injector to confirm that it is firing.

- Compare the sound and performance of each injector to identify any imbalances.

- Fuel Trim Analysis:

Identifying Fuel Injector Imbalances:

* **Compare Fuel Trim Values Between Banks:**

* If your engine has two separate fuel banks, compare the LTFT values for each bank.

* Significant differences between the banks may indicate fuel injector imbalances.

* **Monitor Misfire Counts by Cylinder:**

* Use Blocks 015 and 016 to identify cylinders with high misfire counts.

* Compare the misfire counts between cylinders to pinpoint imbalances.

* **Conduct Relative Compression Test:**

* Perform a relative compression test using VCDS to assess the mechanical condition of each cylinder.

* Low compression in a cylinder can exacerbate the effects of a faulty fuel injector.

* **Perform Cylinder Balance Test:**

* Perform a cylinder balance test using VCDS to assess the contribution of each cylinder to the overall engine output.

* A cylinder with low contribution could be caused by a faulty fuel injector.Case Study:

* A technician uses VCDS to diagnose a vehicle with a rough idle and reduced power. Fuel trim analysis reveals a positive LTFT of +10% on bank 1 and +3% on bank 2. Misfire monitoring shows high misfire counts on cylinders 1 and 3, which are located on bank 1. Based on this data, the technician concludes that the fuel injectors on bank 1 are likely clogged or malfunctioning. They proceed to clean or replace the fuel injectors on bank 1, which resolves the issue.6. What Other Factors Can Affect Fuel Trim Readings Besides Fuel Injectors?

Besides fuel injectors, several other factors can affect fuel trim readings, including vacuum leaks, oxygen sensor issues, MAF sensor problems, exhaust leaks, and fuel pressure irregularities.

-

Other Factors Affecting Fuel Trim Readings:

- Vacuum Leaks:

- Unmetered air entering the engine through vacuum leaks can cause a lean condition, leading to positive fuel trim values.

- Common sources of vacuum leaks include cracked hoses, faulty intake manifold gaskets, and leaking PCV valves.

- Oxygen Sensor Issues:

- Faulty or aging oxygen sensors can provide inaccurate readings to the ECU, resulting in incorrect fuel trim adjustments.

- Oxygen sensor problems can cause both lean and rich conditions, depending on the nature of the fault.

- MAF Sensor Problems:

- A malfunctioning MAF sensor can provide incorrect airflow data to the ECU, leading to fuel trim errors.

- A dirty or damaged MAF sensor can cause both lean and rich conditions.

- Exhaust Leaks:

- Exhaust leaks near the oxygen sensors can introduce extra air into the exhaust stream, causing the ECU to compensate with fuel trim adjustments.

- Exhaust leaks typically result in lean fuel trim values.

- Fuel Pressure Irregularities:

- Low fuel pressure can cause a lean condition, while high fuel pressure can cause a rich condition.

- Fuel pressure problems can be caused by a faulty fuel pump, fuel pressure regulator, or clogged fuel filter.

- Intake Air Leaks:

- Leaks in the intake manifold or intake runners can cause unmetered air to enter the engine, leading to lean conditions.

- EGR System Issues:

- A malfunctioning EGR valve or system can cause incorrect fuel trim adjustments.

- EGR problems can lead to both lean and rich conditions.

- PCV System Issues:

- A malfunctioning PCV system can cause vacuum leaks or excessive crankcase pressure, affecting fuel trim values.

- Timing Issues:

- Incorrect timing can cause incomplete combustion, leading to high hydrocarbon emissions and affecting fuel trim values.

- Vacuum Leaks:

Troubleshooting Approach:

* **Rule Out Other Potential Causes:** Before assuming that fuel injectors are the problem, rule out other potential causes by checking for vacuum leaks, testing the oxygen sensors and MAF sensor, inspecting the exhaust system, and verifying fuel pressure.

* **Use VCDS to Monitor Relevant Parameters:** Use VCDS to monitor fuel trim values, oxygen sensor readings, MAF sensor readings, and other relevant parameters to gather data and diagnose the problem accurately.

* **Perform Component Tests:** Perform component tests using VCDS or other diagnostic tools to verify the functionality of the oxygen sensors, MAF sensor, fuel pump, and other components.7. How Can Remote Car Coding Support Assist with Fuel Injector Diagnostics and Solutions?

Remote car coding support can assist with fuel injector diagnostics and solutions by providing expert guidance, performing advanced diagnostics, and offering coding solutions to optimize engine performance.

-

Benefits of Remote Car Coding Support for Fuel Injector Issues:

- Expert Guidance: Remote car coding experts can provide guidance on diagnosing fuel injector problems, interpreting VCDS data, and identifying the root cause of the issue.

- Advanced Diagnostics: Remote support can include advanced diagnostics such as performing injector activation tests, monitoring fuel trim values in real-time, and analyzing oxygen sensor readings to pinpoint fuel injector issues.

- Coding Solutions: Remote car coding specialists can offer coding solutions to optimize fuel injector performance, adjust fuel trim settings, and compensate for fuel injector imbalances.

- Access to Specialized Tools and Software: Remote support provides access to specialized tools and software, such as VCDS, that may not be readily available to all technicians.

- Cost Savings: Remote support can save time and money by providing efficient diagnostics and solutions without the need to transport the vehicle to a repair shop.

- Convenience: Remote car coding support can be accessed from anywhere with an internet connection, providing convenient assistance for fuel injector diagnostics and solutions.

Remote Car Coding Support Services for Fuel Injector Issues:

* **Fuel Trim Optimization:** Remote specialists can adjust fuel trim settings in the ECU to compensate for fuel injector imbalances or other fuel delivery problems.

* **Injector Coding:** In some cases, fuel injectors may need to be coded to the ECU to ensure proper operation. Remote support can assist with injector coding procedures.

* **Engine Management System Updates:** Remote car coding experts can update the engine management system software to improve fuel injector control and overall engine performance.

* **Performance Tuning:** Remote specialists can provide performance tuning services to optimize fuel injector performance and increase engine power.8. What Are the Risks of Ignoring Fuel Trim Issues Related to Fuel Injectors?

Ignoring fuel trim issues related to fuel injectors can lead to serious engine problems, reduced performance, increased emissions, and potential engine damage.

-

Potential Risks of Ignoring Fuel Trim Issues:

- Reduced Engine Performance: Fuel trim problems can cause a decrease in engine power, acceleration, and overall performance.

- Increased Fuel Consumption: Ignoring fuel trim issues can lead to increased fuel consumption, resulting in higher fuel costs.

- Increased Emissions: Fuel trim problems can cause the engine to produce excessive emissions, contributing to air pollution.

- Engine Damage: In severe cases, ignoring fuel trim issues can lead to engine damage due to improper combustion, overheating, or detonation.

- Catalytic Converter Damage: Fuel trim problems can cause damage to the catalytic converter, which is an expensive component to replace.

- Rough Idle and Stalling: Fuel trim problems can cause a rough idle and stalling, making the vehicle difficult to drive.

- Misfires: Ignoring fuel trim issues can lead to misfires, which can damage the engine and reduce fuel efficiency.

Consequences of Lean Conditions:

* **Overheating:** Lean conditions can cause the engine to overheat, potentially leading to cylinder head damage or other engine problems.

* **Detonation:** Lean conditions can cause detonation (knocking), which can damage pistons, rods, and other engine components.

* **Increased Wear and Tear:** Lean conditions can increase wear and tear on engine components due to higher operating temperatures and pressures.Consequences of Rich Conditions:

* **Fuel Dilution:** Rich conditions can cause fuel to wash down the cylinder walls, diluting the engine oil and reducing its lubricating properties.

* **Carbon Buildup:** Rich conditions can cause carbon buildup on spark plugs, valves, and other engine components, leading to performance problems.

* **Catalytic Converter Damage:** Rich conditions can cause damage to the catalytic converter due to excessive hydrocarbons in the exhaust.9. How Often Should I Check My Fuel Trims Using VCDS, and What Maintenance Is Recommended?

Checking fuel trims with VCDS should be part of your regular maintenance routine, especially if you notice symptoms like rough idle, reduced performance, or increased fuel consumption. Regular maintenance, including fuel injector cleaning, is also recommended to keep your engine running smoothly.

-

Recommended Frequency for Checking Fuel Trims:

- Every 12 Months or 12,000 Miles: As part of your annual maintenance, check fuel trims to identify potential problems early on.

- When Symptoms Arise: If you notice symptoms like rough idle, reduced performance, increased fuel consumption, or misfires, check fuel trims immediately.

- After Major Engine Work: After performing major engine work, such as replacing oxygen sensors, MAF sensor, or fuel injectors, check fuel trims to ensure proper operation.

- Before and After Performance Tuning: Before and after performance tuning, check fuel trims to optimize engine performance and ensure that the engine is running safely.

Recommended Maintenance for Fuel Injectors:

* **Fuel Injector Cleaning:** Clean fuel injectors every 30,000 to 50,000 miles to remove deposits and maintain proper fuel flow.

* **Fuel Filter Replacement:** Replace the fuel filter every 20,000 to 30,000 miles to prevent contaminants from clogging the fuel injectors.

* **Fuel System Cleaner:** Use a fuel system cleaner every 5,000 to 10,000 miles to help remove deposits and keep the fuel injectors clean.

* **Inspect Fuel Injector Connectors:** Inspect the fuel injector connectors regularly to ensure that they are clean and properly connected.

* **Replace Fuel Injectors (If Necessary):** If fuel injectors are severely clogged or damaged, replace them to restore proper engine performance.10. What Are the Latest Advances in Fuel Injector Technology and VCDS Diagnostics?

Recent advances in fuel injector technology and VCDS diagnostics have improved fuel efficiency, reduced emissions, and enhanced engine performance. These advancements include improved injector designs, direct injection systems, and enhanced diagnostic capabilities.

-

Latest Advances in Fuel Injector Technology:

- Improved Injector Designs:

- Modern fuel injectors feature improved designs that provide more precise fuel delivery, better atomization, and reduced deposits.

- These designs include multi-hole injectors, solenoid injectors, and piezoelectric injectors.

- Direct Injection Systems:

- Direct injection systems inject fuel directly into the combustion chamber, allowing for more precise fuel control and improved fuel efficiency.

- Direct injection systems also reduce emissions and increase engine power.

- High-Pressure Fuel Injection:

- High-pressure fuel injection systems use higher fuel pressures to improve fuel atomization and combustion.

- High-pressure systems also reduce emissions and increase engine power.

- Fuel Injector Control Strategies:

- Modern ECUs use advanced fuel injector control strategies to optimize fuel delivery based on engine conditions.

- These strategies include adaptive learning, closed-loop fuel control, and cylinder-selective fuel injection.

- Improved Injector Designs:

-

Enhanced VCDS Diagnostic Capabilities:

- Improved Fuel Trim Monitoring:

- VCDS has been updated to provide more detailed fuel trim data, including individual cylinder fuel trims and adaptive fuel trim values.

- Injector Activation Tests:

- VCDS now offers injector activation tests that allow you to individually activate each fuel injector to test its functionality.

- Misfire Detection Enhancements:

- VCDS has improved misfire detection capabilities that can identify misfires more accurately and provide information about the cause of the misfire.

- Oxygen Sensor Diagnostics:

- VCDS can now perform more comprehensive oxygen sensor diagnostics, including sensor response time tests and heater circuit tests.

- Data Logging Improvements:

- VCDS has improved data logging capabilities that allow you to record fuel trim values, oxygen sensor readings, and other relevant parameters for analysis.

- Improved Fuel Trim Monitoring:

Do you find fuel trim diagnostics challenging? Contact CAR-CODING.EDU.VN today for expert remote support and ensure your vehicle runs at its best! Our experienced technicians are available to assist you with VCDS diagnostics, fuel injector coding, and other advanced car coding services. Reach us at 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States, or via WhatsApp at +1 (641) 206-8880. Visit our website at CAR-CODING.EDU.VN for more information.

FAQ: VCDS Fuel Trim Measuring Blocks and Fuel Injector Diagnostics

1. Is it safe to perform fuel injector coding remotely?

Yes, when performed by experienced professionals like CAR-CODING.EDU.VN, remote fuel injector coding is safe. We use secure connections and follow industry best practices to ensure the integrity of your vehicle’s ECU.

2. What equipment do I need for remote car coding assistance?

You will typically need a laptop, a stable internet connection, a VCDS interface, and the VCDS software. Specific requirements may vary depending on the vehicle and the coding tasks.

3. How much does remote car coding support cost?

The cost of remote car coding support varies depending on the complexity of the task and the time required. Contact CAR-CODING.EDU.VN for a personalized quote.

4. What types of vehicles do you support for remote coding?

CAR-CODING.EDU.VN supports a wide range of vehicles, including Audi, BMW, Volkswagen, Mercedes-Benz, and more. Contact us to confirm compatibility with your vehicle.

5. Can remote coding activate hidden features in my car?

Yes, remote coding can often activate hidden features in your car, such as cornering lights, enhanced displays, and other customizable options.

6. How long does a remote coding session typically take?

The duration of a remote coding session varies depending on the complexity of the task. Simple coding tasks may take 30 minutes, while more complex tasks may take several hours.

7. What happens if the remote coding process is interrupted?

In the event of an interruption, CAR-CODING.EDU.VN will work with you to resume the coding process safely and efficiently. Our experts take precautions to minimize the risk of data loss or damage.

8. Do I need to have technical knowledge to use remote car coding services?

While some technical knowledge is helpful, it is not required. CAR-CODING.EDU.VN provides clear instructions and guidance throughout the remote coding process.

9. Can remote coding void my car’s warranty?

In some cases, coding modifications can void your car’s warranty. Check with your dealer or warranty provider before performing any coding changes.

10. How can I schedule a remote car coding session with CAR-CODING.EDU.VN?

You can schedule a remote car coding session by contacting CAR-CODING.EDU.VN via WhatsApp at +1 (641) 206-8880 or by visiting our website at CAR-CODING.EDU.VN. Our experts are ready to assist you with all your car coding needs.