Is your Vcds Camshaft Adjustment Test showing incorrect readings, and you’re struggling to achieve precise engine timing? At CAR-CODING.EDU.VN, we understand the complexities of modern automotive coding and offer expert remote support to get your engine running smoothly. Our specialists provide secure and efficient assistance with VCDS camshaft adjustment tests, ECU programming, and hidden feature activation, ensuring accurate results.

Contents

- 1. Understanding the VCDS Camshaft Adjustment Test

- 1.1 What is the VCDS Camshaft Adjustment Test?

- 1.2 Why is Camshaft Timing Important?

- 1.3 What Parameters are Monitored During the Test?

- 1.4 What Does a Negative or Positive Reading Indicate?

- 1.5 What is the Acceptable Tolerance?

- 2. Common Issues Encountered During Camshaft Adjustment

- 2.1 Incorrect Installation of Timing Belt or Chain

- 2.2 Worn or Damaged Timing Belt or Chain

- 2.3 Faulty Camshaft Adjuster

- 2.4 Issues with Camshaft Position Sensor

- 2.5 Oil Pressure Problems

- 3. Step-by-Step Guide to Performing a VCDS Camshaft Adjustment Test

- 3.1 Preparing for the Test

- 3.2 Accessing Measuring Blocks

- 3.3 Reading Camshaft Timing Parameters

- 3.4 Interpreting the Results

- 3.5 Performing Camshaft Adjustment (If Necessary)

- 4. Common VCDS Codes Related to Camshaft Adjustment

- 5. The Role of CAR-CODING.EDU.VN in Camshaft Adjustment

- 5.1 Expert Remote Support

- 5.2 ECU Programming and Coding

- 5.3 Hidden Feature Activation

- 5.4 Why Choose CAR-CODING.EDU.VN?

- 6. Understanding Engine Timing and Its Importance

- 6.1 What is Engine Timing?

- 6.2 The Importance of Proper Timing

- 6.3 Key Components Involved in Engine Timing

- 6.4 How Engine Timing Works

- 6.5 Factors Affecting Engine Timing

- 7. Deep Dive into Variable Valve Timing (VVT) Systems

- 7.1 What is Variable Valve Timing?

- 7.2 How VVT Systems Work

- 7.3 Types of VVT Systems

- 7.4 Benefits of VVT Systems

- 7.5 Common VVT System Problems

- 8. Best Practices for Accurate Camshaft Adjustment

- 8.1 Use High-Quality Tools and Equipment

- 8.2 Follow the Vehicle’s Repair Manual

- 8.3 Double-Check Alignment Marks

- 8.4 Use a Torque Wrench

- 8.5 Clear Fault Codes After Adjustment

- 8.6 Re-Test After Adjustment

- 9. CAR-CODING.EDU.VN: Your Partner in Automotive Excellence

- 9.1 Comprehensive Coding and Programming Services

- 9.2 Experienced and Certified Technicians

- 9.3 State-of-the-Art Equipment

- 9.4 Customer Satisfaction Guarantee

- 9.5 Contact Us Today

- 10. Frequently Asked Questions (FAQ) About VCDS Camshaft Adjustment

- 10.1 Is it Safe to Perform a Camshaft Adjustment Test with VCDS?

- 10.2 Can CAR-CODING.EDU.VN Assist Me Remotely with Camshaft Adjustment?

- 10.3 How Much Does Remote Support for Camshaft Adjustment Cost?

- 10.4 What Types of Vehicles Can CAR-CODING.EDU.VN Support?

- 10.5 What Equipment Do I Need for Remote Support?

- 10.6 What if I Damage My ECU During the Adjustment Process?

- 10.7 Can CAR-CODING.EDU.VN Activate Hidden Features in My Vehicle?

- 10.8 How Long Does a Remote Camshaft Adjustment Session Take?

- 10.9 What Happens if the Remote Session is Unsuccessful?

- 10.10 How Can I Schedule a Remote Support Session?

1. Understanding the VCDS Camshaft Adjustment Test

1.1 What is the VCDS Camshaft Adjustment Test?

The VCDS (VAG-COM Diagnostic System) camshaft adjustment test is a diagnostic procedure used to verify and adjust the camshaft timing on Volkswagen Audi Group (VAG) vehicles. It utilizes the VCDS software to read and interpret data from engine sensors, particularly those related to camshaft position and crankshaft position. By comparing these readings, technicians can determine if the camshaft timing is within the specified parameters.

1.2 Why is Camshaft Timing Important?

Camshaft timing is critical for optimal engine performance, fuel efficiency, and emissions control. Incorrect camshaft timing can lead to:

- Reduced power and torque

- Poor fuel economy

- Increased emissions

- Engine knocking or misfires

- Potential engine damage

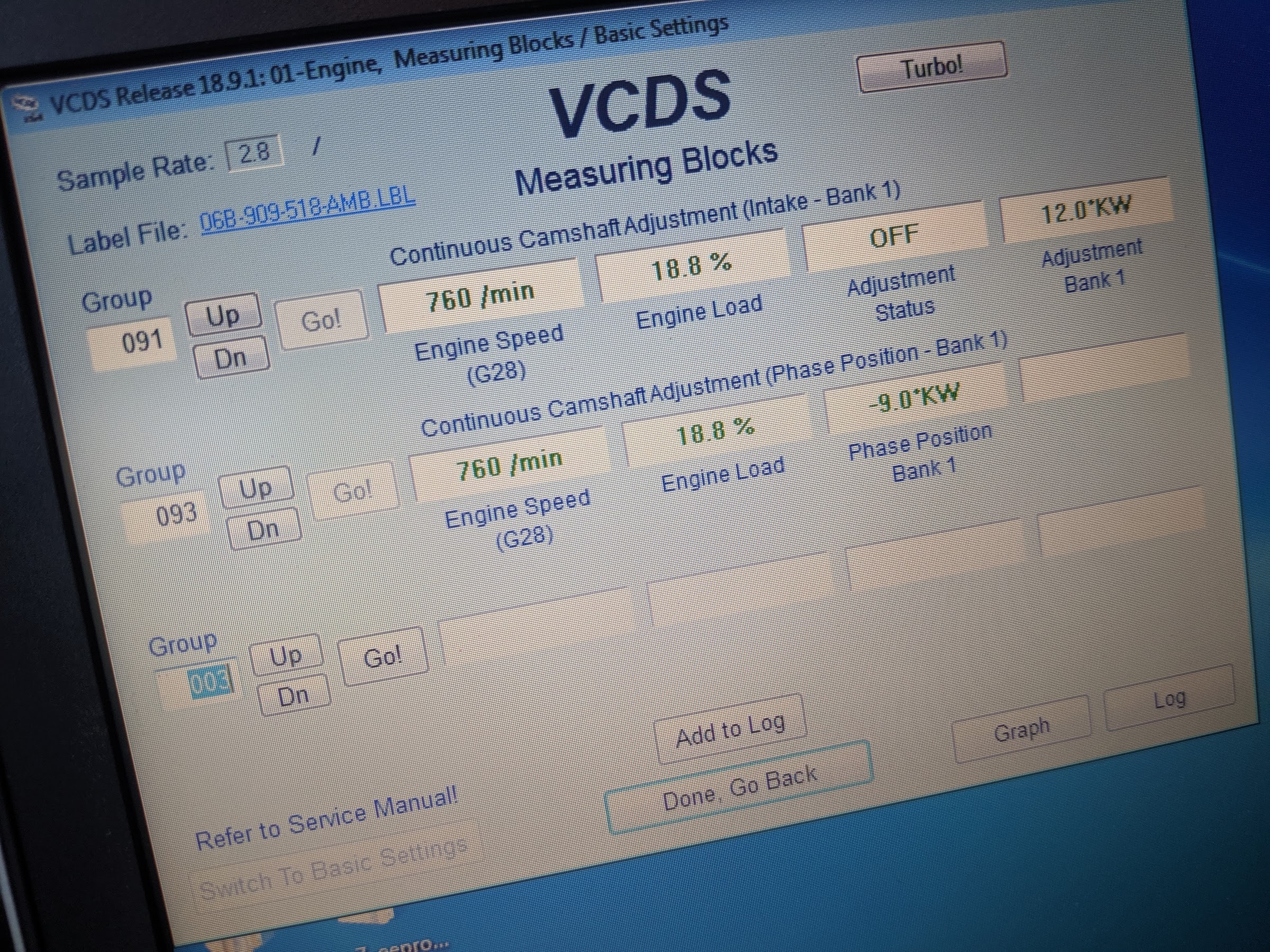

1.3 What Parameters are Monitored During the Test?

During a VCDS camshaft adjustment test, several parameters are monitored, including:

- Phase Position Bank 1: This reading indicates the deviation of the intake camshaft position from the desired value. Ideally, this should be close to 0 degrees.

- Adjustment Bank 1: This value reflects the actual adjustment made by the camshaft adjuster.

- Camshaft Adaptation Values: These values show the learned adjustments made by the ECU to compensate for wear or slight timing variations.

1.4 What Does a Negative or Positive Reading Indicate?

- Negative Reading: A negative reading in the Phase Position Bank 1 (e.g., -11 degrees KW) typically indicates that the camshaft is retarded, meaning it is lagging behind the crankshaft.

- Positive Reading: A positive reading indicates that the camshaft is advanced, meaning it is ahead of the crankshaft.

1.5 What is the Acceptable Tolerance?

The acceptable tolerance for the Phase Position Bank 1 reading is typically +/- 6 degrees. Any reading outside this range suggests that the camshaft timing is not within the specified parameters and requires adjustment.

2. Common Issues Encountered During Camshaft Adjustment

2.1 Incorrect Installation of Timing Belt or Chain

One of the most common causes of incorrect camshaft timing is the improper installation of the timing belt or chain. This can occur if the marks on the camshaft and crankshaft pulleys are not aligned correctly during installation.

2.2 Worn or Damaged Timing Belt or Chain

A worn or stretched timing belt or chain can also cause camshaft timing issues. As the belt or chain wears, it can elongate, leading to a change in the relative positions of the camshaft and crankshaft.

2.3 Faulty Camshaft Adjuster

The camshaft adjuster, also known as the variable valve timing (VVT) actuator, is responsible for dynamically adjusting the camshaft timing based on engine load and speed. A faulty camshaft adjuster can cause incorrect timing, leading to performance issues.

2.4 Issues with Camshaft Position Sensor

The camshaft position sensor provides the ECU with information about the camshaft’s position. A faulty or misaligned sensor can provide incorrect data, leading to inaccurate camshaft timing adjustments.

2.5 Oil Pressure Problems

Some VVT systems rely on oil pressure to actuate the camshaft adjuster. Low oil pressure due to a faulty oil pump or clogged oil passages can affect the adjuster’s performance and lead to timing issues.

3. Step-by-Step Guide to Performing a VCDS Camshaft Adjustment Test

3.1 Preparing for the Test

-

Gather Necessary Tools and Equipment:

- VCDS software and interface cable

- Laptop with VCDS installed

- Vehicle repair manual for specific engine

- Basic hand tools (wrenches, sockets, etc.)

-

Connect VCDS to the Vehicle:

- Locate the OBD-II port on your vehicle (usually under the dashboard).

- Plug the VCDS interface cable into the OBD-II port and connect it to your laptop.

- Turn on the vehicle’s ignition but do not start the engine.

-

Launch VCDS Software:

- Open the VCDS software on your laptop.

- Select the appropriate control module (usually Engine).

3.2 Accessing Measuring Blocks

-

Select “Select Control Module”:

- In VCDS, choose the “Select Control Module” option.

-

Choose Engine Control Module:

- Select the engine control module (usually labeled as “01-Engine”).

-

Access Measuring Blocks:

- Click on “Measuring Blocks – 08”.

3.3 Reading Camshaft Timing Parameters

-

Enter Group Numbers:

- Enter the appropriate group numbers for camshaft timing parameters. Common group numbers include 091 and 093. Refer to your vehicle’s repair manual for specific group numbers.

-

Record Values:

- Record the values displayed for Phase Position Bank 1 and Adjustment Bank 1. Note whether the Phase Position Bank 1 reading is within the acceptable tolerance (+/- 6 degrees).

3.4 Interpreting the Results

-

Evaluate Phase Position Bank 1:

- If the Phase Position Bank 1 reading is outside the acceptable tolerance, further investigation and adjustment are required.

-

Check Adjustment Bank 1:

- Observe the Adjustment Bank 1 value to see how much the camshaft adjuster is compensating. A high value may indicate a problem with the adjuster itself.

-

Review Camshaft Adaptation Values:

- If available, review the camshaft adaptation values to understand the ECU’s learned adjustments.

3.5 Performing Camshaft Adjustment (If Necessary)

-

Adjust Timing Belt or Chain:

- If the timing is off due to improper installation, carefully adjust the timing belt or chain according to the vehicle’s repair manual.

- Ensure that the marks on the camshaft and crankshaft pulleys are correctly aligned.

-

Test Camshaft Adjuster:

- Use VCDS to test the camshaft adjuster. You may need to perform an output test to activate the adjuster and observe its response.

-

Clear Fault Codes:

- After making adjustments, clear any related fault codes using VCDS.

-

Re-Test Camshaft Timing:

- Repeat the VCDS camshaft adjustment test to verify that the timing is now within the specified parameters.

4. Common VCDS Codes Related to Camshaft Adjustment

| Code | Description | Possible Causes |

|---|---|---|

| P0011 | Camshaft Position A – Timing Over-Advanced or System Performance (Bank 1) | Incorrect camshaft timing, faulty camshaft adjuster, low oil pressure, faulty camshaft position sensor |

| P0012 | Camshaft Position A – Timing Over-Retarded (Bank 1) | Incorrect camshaft timing, faulty camshaft adjuster, low oil pressure, faulty camshaft position sensor |

| P0016 | Crankshaft Position – Camshaft Position Correlation (Bank 1 Sensor A) | Incorrect camshaft timing, stretched timing chain, faulty camshaft position sensor, faulty crankshaft position sensor |

| P0017 | Crankshaft Position – Camshaft Position Correlation (Bank 1 Sensor B) | Incorrect camshaft timing, stretched timing chain, faulty camshaft position sensor, faulty crankshaft position sensor |

| P0340 | Camshaft Position Sensor A Circuit (Bank 1 or Single Sensor) | Faulty camshaft position sensor, wiring issues, poor connection |

| P0341 | Camshaft Position Sensor A Circuit Range/Performance (Bank 1 or Single Sensor) | Faulty camshaft position sensor, incorrect camshaft timing, wiring issues |

| P0342 | Camshaft Position Sensor A Circuit Low Input (Bank 1 or Single Sensor) | Faulty camshaft position sensor, wiring issues, low voltage |

| P0343 | Camshaft Position Sensor A Circuit High Input (Bank 1 or Single Sensor) | Faulty camshaft position sensor, wiring issues, high voltage |

| P0346 | Camshaft Position Sensor B Circuit Range/Performance (Bank 2) | Faulty camshaft position sensor, incorrect camshaft timing, wiring issues |

| P0347 | Camshaft Position Sensor B Circuit Low Input (Bank 2) | Faulty camshaft position sensor, wiring issues, low voltage |

| P0348 | Camshaft Position Sensor B Circuit High Input (Bank 2) | Faulty camshaft position sensor, wiring issues, high voltage |

5. The Role of CAR-CODING.EDU.VN in Camshaft Adjustment

5.1 Expert Remote Support

CAR-CODING.EDU.VN offers expert remote support for VCDS camshaft adjustment tests. Our experienced technicians can guide you through the testing and adjustment process, providing real-time assistance to ensure accurate results.

5.2 ECU Programming and Coding

In some cases, camshaft timing issues may require ECU programming or coding. CAR-CODING.EDU.VN specializes in ECU programming and coding for a wide range of VAG vehicles, ensuring optimal engine performance and reliability.

5.3 Hidden Feature Activation

In addition to camshaft adjustment and ECU programming, CAR-CODING.EDU.VN can also activate hidden features in your vehicle. These features can enhance your driving experience and add convenience to your vehicle.

5.4 Why Choose CAR-CODING.EDU.VN?

- Expertise: Our technicians have extensive experience with VCDS camshaft adjustment tests and ECU programming.

- Remote Support: We provide remote support, allowing you to perform the tests and adjustments from the comfort of your own garage.

- Affordable: Our services are competitively priced, offering a cost-effective solution for your automotive needs.

- Safe and Secure: We use secure connections and follow industry best practices to ensure the safety of your vehicle’s ECU.

6. Understanding Engine Timing and Its Importance

6.1 What is Engine Timing?

Engine timing refers to the precise coordination of various engine components, including the crankshaft, camshaft(s), valves, and pistons. Proper engine timing ensures that the valves open and close at the correct moments in relation to the piston’s position, allowing for optimal combustion and engine performance.

6.2 The Importance of Proper Timing

Proper engine timing is crucial for several reasons:

- Optimal Performance: Correct timing ensures that the engine produces the maximum power and torque.

- Fuel Efficiency: Accurate timing optimizes the combustion process, leading to improved fuel economy.

- Emissions Control: Proper timing helps reduce harmful emissions by ensuring complete combustion.

- Engine Longevity: Incorrect timing can cause engine knocking and stress on engine components, potentially leading to premature wear and damage.

6.3 Key Components Involved in Engine Timing

- Crankshaft: The crankshaft is the main rotating component of the engine, converting the linear motion of the pistons into rotary motion.

- Camshaft: The camshaft controls the opening and closing of the engine’s valves. It is driven by the crankshaft via a timing belt or chain.

- Valves: The valves allow air and fuel to enter the combustion chamber and exhaust gases to exit.

- Pistons: The pistons move up and down within the cylinders, compressing the air-fuel mixture and transferring the force of combustion to the crankshaft.

6.4 How Engine Timing Works

The engine’s timing system ensures that the camshaft and crankshaft are synchronized. The timing belt or chain connects the crankshaft and camshaft, maintaining a precise relationship between their rotational speeds. As the crankshaft rotates, it drives the camshaft, which in turn opens and closes the valves at specific times in the engine’s cycle.

6.5 Factors Affecting Engine Timing

Several factors can affect engine timing, including:

- Timing Belt or Chain Wear: As the timing belt or chain wears, it can stretch, altering the timing relationship between the crankshaft and camshaft.

- Timing Belt or Chain Installation: Improper installation of the timing belt or chain can result in incorrect timing.

- Camshaft Adjuster Malfunction: A faulty camshaft adjuster can cause the timing to deviate from the specified parameters.

- Sensor Issues: Faulty crankshaft or camshaft position sensors can provide incorrect data to the ECU, affecting timing adjustments.

7. Deep Dive into Variable Valve Timing (VVT) Systems

7.1 What is Variable Valve Timing?

Variable Valve Timing (VVT) is a technology used in modern engines to dynamically adjust the timing of the intake and/or exhaust valves. VVT systems optimize engine performance, fuel efficiency, and emissions by varying the valve timing based on engine speed, load, and other factors.

7.2 How VVT Systems Work

VVT systems typically use a camshaft adjuster (also known as a phaser) to alter the relationship between the camshaft and crankshaft. The adjuster can advance or retard the camshaft timing, changing the valve opening and closing events.

7.3 Types of VVT Systems

- Cam Phasing: This type of VVT system adjusts the overall timing of the intake and/or exhaust valves.

- Valve Lift Control: This system varies the amount the valves open, allowing for greater control over airflow into the engine.

- Combined Systems: Some VVT systems combine cam phasing and valve lift control for even greater flexibility.

7.4 Benefits of VVT Systems

- Improved Performance: VVT systems optimize valve timing for different engine speeds and loads, resulting in increased power and torque.

- Enhanced Fuel Efficiency: By optimizing valve timing, VVT systems improve combustion efficiency, leading to better fuel economy.

- Reduced Emissions: VVT systems help reduce harmful emissions by ensuring complete combustion and minimizing unburned hydrocarbons.

- Smoother Idle: VVT systems can improve idle stability by adjusting valve timing at low engine speeds.

7.5 Common VVT System Problems

- Faulty Camshaft Adjuster: A malfunctioning camshaft adjuster can cause incorrect valve timing and trigger fault codes.

- Low Oil Pressure: VVT systems often rely on oil pressure to actuate the camshaft adjuster. Low oil pressure can affect the adjuster’s performance.

- Sensor Issues: Faulty camshaft or crankshaft position sensors can provide incorrect data to the ECU, affecting VVT system operation.

- Clogged Oil Passages: Clogged oil passages can restrict oil flow to the camshaft adjuster, causing it to malfunction.

8. Best Practices for Accurate Camshaft Adjustment

8.1 Use High-Quality Tools and Equipment

When performing a VCDS camshaft adjustment test, it is essential to use high-quality tools and equipment. This includes a reliable VCDS interface cable, a stable laptop with the latest VCDS software, and appropriate hand tools.

8.2 Follow the Vehicle’s Repair Manual

Always refer to the vehicle’s repair manual for specific instructions and torque specifications. The repair manual provides detailed information about the engine’s timing system, including the correct alignment marks and adjustment procedures.

8.3 Double-Check Alignment Marks

Before tightening any components, double-check that the alignment marks on the camshaft and crankshaft pulleys are correctly aligned. Incorrect alignment can lead to inaccurate camshaft timing and potential engine damage.

8.4 Use a Torque Wrench

When tightening bolts and nuts, use a torque wrench to ensure that they are tightened to the correct specifications. Over-tightening or under-tightening can damage components and affect engine timing.

8.5 Clear Fault Codes After Adjustment

After making adjustments to the camshaft timing, clear any related fault codes using VCDS. This will prevent the ECU from using old data and ensure that the engine operates correctly.

8.6 Re-Test After Adjustment

After clearing the fault codes, re-test the camshaft timing using VCDS to verify that the timing is now within the specified parameters. If the timing is still incorrect, repeat the adjustment process until the desired results are achieved.

9. CAR-CODING.EDU.VN: Your Partner in Automotive Excellence

9.1 Comprehensive Coding and Programming Services

CAR-CODING.EDU.VN offers a wide range of coding and programming services for various vehicle makes and models. Our services include:

- ECU Programming

- Key Coding

- Remote Diagnostics

- Hidden Feature Activation

- Fault Code Clearing

9.2 Experienced and Certified Technicians

Our team of technicians is highly experienced and certified in automotive coding and programming. We stay up-to-date with the latest technologies and techniques to provide you with the best possible service.

9.3 State-of-the-Art Equipment

We use state-of-the-art equipment and software to ensure accurate and reliable results. Our remote support system allows us to connect to your vehicle from anywhere in the world, providing you with convenient and efficient service.

9.4 Customer Satisfaction Guarantee

We are committed to providing our customers with the highest level of satisfaction. If you are not completely satisfied with our services, we will work with you to make it right.

9.5 Contact Us Today

If you are experiencing camshaft timing issues or need assistance with VCDS camshaft adjustment, contact CAR-CODING.EDU.VN today. Our expert technicians are ready to help you get your vehicle running smoothly and efficiently.

10. Frequently Asked Questions (FAQ) About VCDS Camshaft Adjustment

10.1 Is it Safe to Perform a Camshaft Adjustment Test with VCDS?

Yes, it is generally safe to perform a camshaft adjustment test with VCDS, provided you follow the correct procedures and have a basic understanding of automotive diagnostics. However, if you are not comfortable working on your vehicle, it is best to seek professional assistance from CAR-CODING.EDU.VN.

10.2 Can CAR-CODING.EDU.VN Assist Me Remotely with Camshaft Adjustment?

Yes, CAR-CODING.EDU.VN offers remote support for VCDS camshaft adjustment tests. Our experienced technicians can guide you through the testing and adjustment process, providing real-time assistance to ensure accurate results.

10.3 How Much Does Remote Support for Camshaft Adjustment Cost?

The cost of remote support for camshaft adjustment varies depending on the complexity of the issue and the vehicle’s make and model. Contact CAR-CODING.EDU.VN for a personalized quote.

10.4 What Types of Vehicles Can CAR-CODING.EDU.VN Support?

CAR-CODING.EDU.VN supports a wide range of vehicles, including Volkswagen, Audi, SEAT, and Skoda models.

10.5 What Equipment Do I Need for Remote Support?

To receive remote support from CAR-CODING.EDU.VN, you will need a VCDS interface cable, a laptop with VCDS software installed, and a stable internet connection.

10.6 What if I Damage My ECU During the Adjustment Process?

While it is rare to damage the ECU during a camshaft adjustment test, it is essential to follow the correct procedures and take precautions. CAR-CODING.EDU.VN provides expert guidance to minimize the risk of damage.

10.7 Can CAR-CODING.EDU.VN Activate Hidden Features in My Vehicle?

Yes, in addition to camshaft adjustment and ECU programming, CAR-CODING.EDU.VN can also activate hidden features in your vehicle, enhancing your driving experience.

10.8 How Long Does a Remote Camshaft Adjustment Session Take?

The duration of a remote camshaft adjustment session depends on the complexity of the issue and the vehicle’s make and model. Most sessions typically take between 1 to 3 hours.

10.9 What Happens if the Remote Session is Unsuccessful?

If the remote session is unsuccessful, CAR-CODING.EDU.VN will provide you with alternative solutions or recommend a local mechanic for further assistance.

10.10 How Can I Schedule a Remote Support Session?

To schedule a remote support session, contact CAR-CODING.EDU.VN via our website or WhatsApp. Our team will assist you in setting up an appointment.

Having trouble with your VCDS camshaft adjustment test? Don’t risk damaging your engine with improper timing. Contact CAR-CODING.EDU.VN today for expert remote assistance. Our team of skilled technicians will guide you through the process, ensuring accurate results and optimal engine performance. Whether you’re facing coding challenges, ECU programming needs, or seeking to unlock hidden features, we’re here to provide safe, efficient, and reliable support. Reach out now for immediate help with ECU flashing, variant coding, and comprehensive automotive coding solutions. Contact us at our US support office: 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States, or WhatsApp: +1 (641) 206-8880. Visit our website at CAR-CODING.EDU.VN to learn more and schedule your remote support session today.

engine-components

engine-components