Is your car’s performance suffering? Checking injector values with VCDS can help identify potential problems. CAR-CODING.EDU.VN provides expert remote support for diagnosing and resolving complex car coding issues, including injector-related problems. Get the assistance you need to ensure your vehicle runs smoothly. Our services include ECU programming, fault code clearing, and feature activation.

Contents

- 1. Understanding Injector Function and Importance

- 2. Common Causes of Injector Issues

- 3. Symptoms of Failing Injectors

- 4. Checking Injector Values on 1.6, 1.9, and 2.0 TDI Engines

- 5. Testing Injectors/High-Pressure Rail on 2.0 FSI, TSI, and TFSI Engines

- 6. Diagnosing Injector Problems on 2.7 and 3.0 V6 TDI Common Rail Engines

- 7. FAQ: Injector Values and VCDS

- 1. Is it safe to perform injector coding myself?

- 2. What is the process for remote support from CAR-CODING.EDU.VN?

- 3. How much does remote injector coding support cost?

- 4. What types of vehicles and features does CAR-CODING.EDU.VN support?

- 5. What equipment do I need to use CAR-CODING.EDU.VN’s remote support services?

- 6. How can I ensure the safety of my vehicle during remote coding?

- 7. What are the benefits of coding injectors correctly?

- 8. How quickly can CAR-CODING.EDU.VN provide remote support?

- 9. What if something goes wrong during the coding process?

- 10. Can CAR-CODING.EDU.VN help with other car coding issues besides injector coding?

- 8. Need Help? Contact CAR-CODING.EDU.VN Today

Table of Contents:

- Understanding Injector Function and Importance

- Common Causes of Injector Issues

- Symptoms of Failing Injectors

- Checking Injector Values on 1.6, 1.9, and 2.0 TDI Engines

- Testing Injectors/High-Pressure Rail on 2.0 FSI, TSI, and TFSI Engines

- Diagnosing Injector Problems on 2.7 and 3.0 V6 TDI Common Rail Engines

- FAQ: Injector Values and VCDS

- Need Help? Contact CAR-CODING.EDU.VN Today

1. Understanding Injector Function and Importance

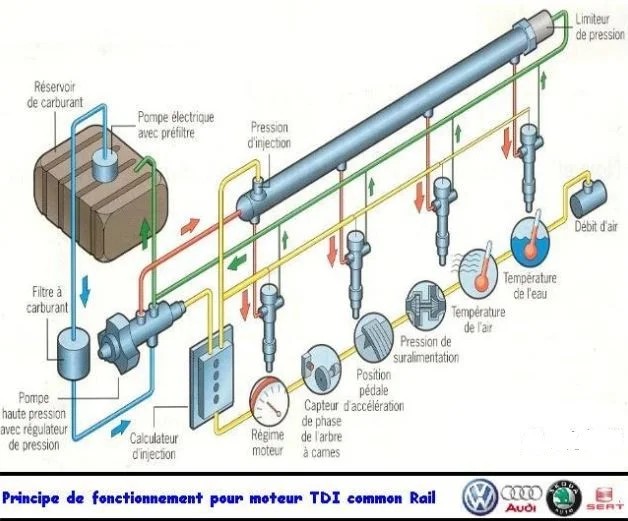

What is the role of fuel injectors in a car’s engine? Fuel injectors are critical components responsible for atomizing and delivering fuel into the engine’s cylinders. Located either at the intake manifold or directly in the cylinder, the injector sprays fuel in microscopic droplets to ensure efficient combustion.

Fuel injectors ensure the proper air-fuel mixture is delivered to the engine, which is essential for starting and running smoothly. The injection system calculates the correct fuel-to-air ratio to optimize combustion. Modern electronic injection systems enhance engine performance, reduce fuel consumption, and decrease emissions.

2. Common Causes of Injector Issues

What causes fuel injector issues? Injector problems often stem from fuel quality and combustion byproducts. While injectors are designed to last, they can become clogged or damaged by various factors.

Common causes include:

- Poor Fuel Quality: Low-quality fuel can contain contaminants that clog injectors.

- Carbon Deposits: Combustion produces carbon deposits that accumulate in the injectors.

- Residue Build-up: Residue from fuel combustion can obstruct the injectors.

- Infrequent Maintenance: Lack of regular maintenance can exacerbate these issues.

3. Symptoms of Failing Injectors

What are the signs of a failing fuel injector? Identifying the symptoms of a failing injector early can prevent further engine damage. Here are common signs to watch for:

- Engine Power Loss: Reduced power and acceleration indicate a potential injector problem.

- Black Exhaust Smoke: Incomplete combustion due to faulty injectors can cause black smoke.

- Increased Fuel Consumption: Failing injectors may deliver too much fuel, increasing consumption.

- Erratic Idling: Rough or unstable idling can be a sign of injector issues.

- Difficulty Starting: A clogged or malfunctioning injector can make starting the engine difficult.

- Persistent Fuel Odor: A strong fuel smell may indicate a leaking injector.

- Acceleration Hesitation: Delays or stumbles during acceleration suggest an injector problem.

If your vehicle exhibits these symptoms, it’s crucial to check the injectors using VCDS to identify any defects before considering replacement.

4. Checking Injector Values on 1.6, 1.9, and 2.0 TDI Engines

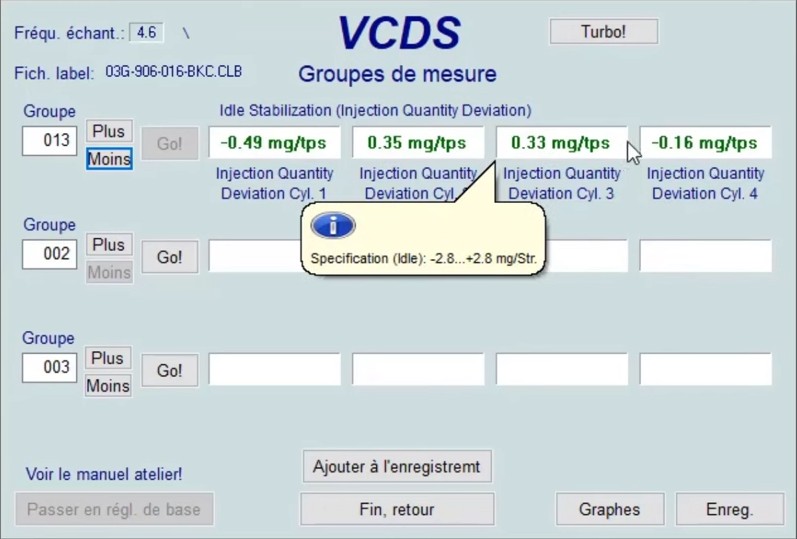

How can I check injector values on my 1.6, 1.9, or 2.0 TDI engine using VCDS? Checking injector values with VCDS can help identify malfunctioning injectors and ensure optimal engine performance. Here’s how to do it:

Checking Injector Values on TDI Engines with VCDS: Ensure optimal engine performance by identifying malfunctioning injectors with the help of VCDS

Checking Injector Values on TDI Engines with VCDS: Ensure optimal engine performance by identifying malfunctioning injectors with the help of VCDS

Applicable Models: VW Golf 5/6, Polo 4/5, Audi A3 8P, Seat Ibiza 6L/6P, Leon, and other models with 1.6, 1.9, and 2.0 TDI Common Rail engines.

Procedure:

- Connect VCDS: With the engine off and ignition off, connect your VAG-COM VCDS cable to your computer and the vehicle’s diagnostic port.

- Start VCDS and Engine: Turn on the ignition, launch the VCDS program, and start the engine.

- Select Engine Control Module: Click “Select” and then “01 – Engine.”

- Access Measuring Blocks: Click “Measuring Blocks – 08.”

- Select Group 013: Enter “013” to view the injector deviation values.

Injector Deviation Values in VCDS: Monitoring injector deviation values in VCDS

Injector Deviation Values in VCDS: Monitoring injector deviation values in VCDS

Interpretation:

At idle, the engine control unit (ECU) adjusts each injector’s flow rate relative to a theoretical value to maintain smooth engine operation. A deviation exceeding +1.5 mg/stroke is considered abnormal but may not always indicate an injector issue. Values above +2.8 mg/stroke usually signify a faulty injector.

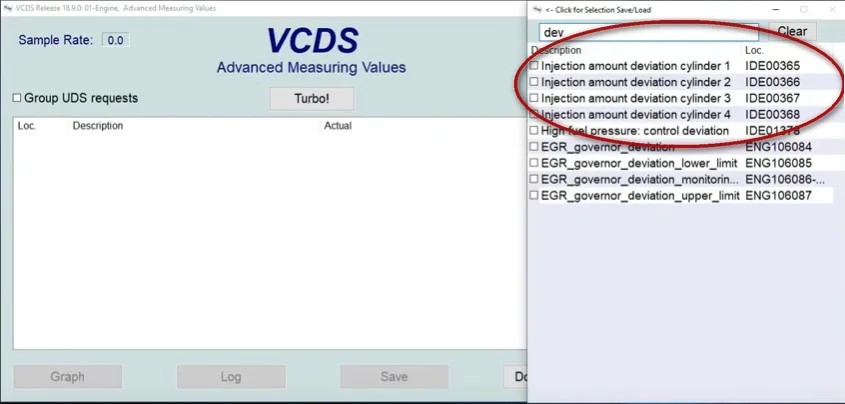

If “Measuring Blocks – 08” is grayed out, use “Advanced Measuring Values.” Search for “injection” or “deviation” and select the lines corresponding to your cylinders.

Advanced Measuring Values for Injector Control in VCDS: Utilizing advanced measuring values for precise injector control diagnostics

Advanced Measuring Values for Injector Control in VCDS: Utilizing advanced measuring values for precise injector control diagnostics

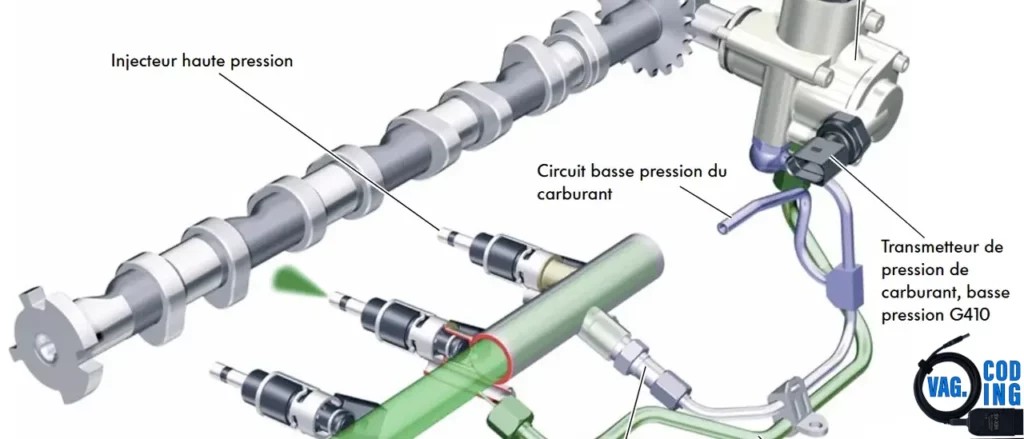

5. Testing Injectors/High-Pressure Rail on 2.0 FSI, TSI, and TFSI Engines

How do I test the high-pressure rail and injectors on a 2.0 FSI, TSI, or TFSI engine? Testing the high-pressure rail and injectors can identify leaks and other issues affecting engine performance. This test helps determine if any injectors are leaking, which can cause various engine problems.

Applicable Models: VW Golf 5/6/7 GTI, VW Golf 6R/7R, Audi S3 8P/8V, and other models with 2.0 EA113 engines.

Injector Function Reminder:

The injectors in TFSI engines are high-pressure injectors operating with direct injection (fuel injected directly into the combustion chamber). This section generally applies to all high-pressure injection engines (FSI, TFSI).

During injection, the magnetic coil inside the injector is activated, creating a magnetic field that lifts a needle and opens a valve, injecting fuel. When the coil is deactivated, the magnetic field collapses, and the needle is pushed back into the valve seat by a spring, stopping fuel flow.

Injector Components:

- Injector Nozzle: Consists of a nozzle sealed by a needle.

- Electromagnetic Core: Controlled by the ECU, it lifts the needle for injection.

Injection Duration:

Injection duration is crucial and is controlled by the engine management computer, based on sensor readings (engine temperature, accelerator pedal position, intake air pressure, etc.).

VCDS Leak Test for TFSI/TSI Injectors: Detecting leaks in TFSI/TSI injectors using VCDS

VCDS Leak Test for TFSI/TSI Injectors: Detecting leaks in TFSI/TSI injectors using VCDS

Causes of Injector Leaks:

Leaks often result from impurities obstructing the injector. These impurities can either prevent the injector from closing properly (causing a leak) or block fuel flow (causing a clogged injector). Regularly replace the fuel filter every 30,000 km to prevent these issues.

Consequences of Leaking Injectors:

A leaking injector disrupts the injection system and can lead to:

- Fuel Contamination of Oil: Diluted oil loses its lubricating properties.

- Increased Oil Level: Fuel in the oil can cause engine and turbo damage.

- Misfires: Inconsistent combustion.

- Imbalanced Load Distribution: Uneven load distribution among cylinders.

- Harmful Emissions: Exposure to fuel vapors and toxic emissions like carbon monoxide.

Detecting Injector Failure:

Signs of failure include:

- Persistent fuel odor

- Power loss

- Starting problems

- Acceleration jerks

- Exhaust smoke

- Fuel smell when opening the oil filler cap

- Misfires after heavy use

Common fault codes include P0300, P0301 (cylinder 1), P0302 (cylinder 2), P0303 (cylinder 3), and P0304 (cylinder 4).

Before diagnosing an injector problem, rule out issues with ignition coils, spark plugs (replace every 40,000 – 60,000 km), and carbon buildup.

VCDS Test for Injector Leaks:

Perform this test with the engine at optimal operating temperature (90°C).

Procedure:

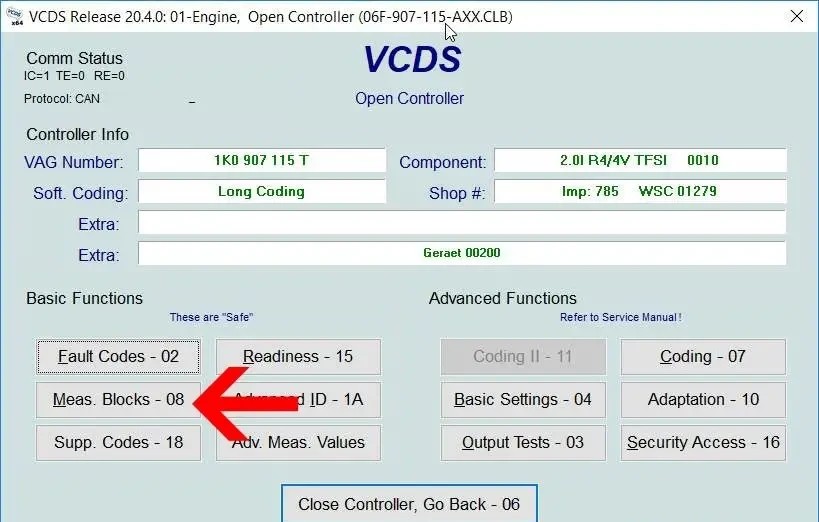

- Connect VCDS: With the engine off and ignition off, connect your VAG-COM VCDS cable to your computer and the vehicle’s diagnostic port.

- Start VCDS and Engine: Turn on the ignition, launch the VCDS program, and start the engine.

- Select Engine Control Module: Click “Select” and then “01 – Engine.”

- Access Measuring Blocks: Click “Measuring Blocks – 08.”

VCDS Measuring Blocks for Injector Leak Test: Selecting appropriate measuring blocks in VCDS for an effective injector leak test

VCDS Measuring Blocks for Injector Leak Test: Selecting appropriate measuring blocks in VCDS for an effective injector leak test

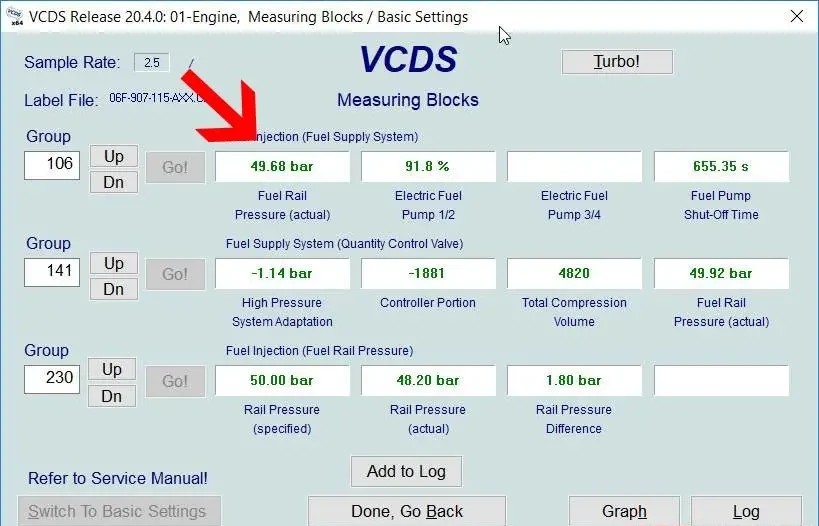

Select channels 106, 141, and 230.

With the engine running, note the rail pressure (e.g., 49.68 bar).

Monitoring Rail Pressure in VCDS for Injector Leak Diagnosis: Monitoring rail pressure through VCDS to diagnose injector leaks accurately

Monitoring Rail Pressure in VCDS for Injector Leak Diagnosis: Monitoring rail pressure through VCDS to diagnose injector leaks accurately

Wait until the coolant temperature reaches 90°C, then turn off the engine.

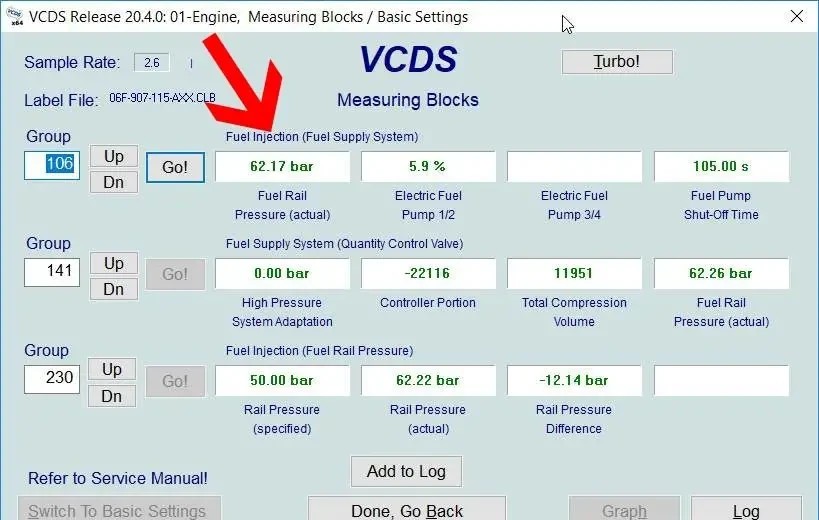

The pressure should gradually increase (e.g., to 62.17 bar).

Observing Pressure Increase in VCDS for Injector Leak Detection: Observing pressure increase via VCDS to accurately detect injector leaks

Observing Pressure Increase in VCDS for Injector Leak Detection: Observing pressure increase via VCDS to accurately detect injector leaks

Monitor the pressure for several minutes. If the pressure does not increase significantly, there is likely a leak.

6. Diagnosing Injector Problems on 2.7 and 3.0 V6 TDI Common Rail Engines

How do I diagnose injector problems on my 2.7 or 3.0 V6 TDI engine using VCDS? Diagnosing injector issues on these engines often involves checking for white smoke and engine shaking, especially after long drives. These symptoms may indicate worn injector seats.

1. White Smoke from Exhaust:

White smoke can result from:

- Unburnt Fuel: Worn injector seats can cause excessive fuel injection, leading to incomplete combustion and white smoke.

- Cooling System Issues: A faulty head gasket can allow coolant to enter the combustion chambers, also producing white smoke. Check for coolant loss or bubbles in the coolant reservoir.

2. Engine Shaking:

Shaking, particularly at idle after extended operation, may be related to:

- Faulty Injectors: Worn or defective injectors can cause irregular fuel injection, leading to engine vibrations.

- Combustion Problems: Poor fuel combustion due to injector issues can also cause shaking and rough idling.

To evaluate the condition of your vehicle’s injectors using measuring block values 72 to 77 with VCDS, follow this detailed guide:

Reading Measurement Block Values:

Procedure:

- Connect VCDS: With the engine off and ignition off, connect your VAG-COM VCDS cable to your computer and the vehicle’s diagnostic port.

- Start VCDS: Turn on the ignition and launch the VCDS program.

- Select Engine Control Module: Click “Select” and then “01 – Engine.”

- Access Measuring Blocks: Click “Measuring Blocks – 08.”

- Select Groups 72 to 77: Enter “72” through “77” to view the injector values.

6. Interpreting Values: Each measurement group displays three values corresponding to different pressure levels (300 bar, 600 bar, 1,000 bar). These values are in milliseconds (ms) and require careful reading.

Analyzing Results:

Examine the values for each group and compare them to the indicated thresholds. Here’s how to interpret the provided values:

Group 72

- Values: -50 ms, -14 ms, -6 ms

- Analysis: The first value (-50 ms) is below the threshold of -45 ms, potentially indicating significant wear of the needle seat for the corresponding injector.

Group 73

- Values: -24 ms, -4 ms, -2 ms

- Analysis: None of the values exceed the critical thresholds. The injectors appear to be in good condition.

Group 74

- Values: -24 ms, -4 ms, -6 ms

- Analysis: None of the values exceed the critical thresholds. The injectors appear to be in good condition.

Group 75

- Values: -54 ms, -12 ms, -6 ms

- Analysis: The first value (-54 ms) exceeds the critical threshold of -45 ms, potentially indicating significant wear of the needle seat.

Group 76

- Values: -36 ms, -6 ms, -6 ms

- Analysis: None of the values exceed the critical thresholds. The injectors appear to be in good condition.

Group 77

- Values: -48 ms, -12 ms, -6 ms

- Analysis: The first value (-48 ms) exceeds the critical threshold of -45 ms, potentially indicating significant wear of the needle seat.

Conclusion and Actions:

- Defective Injectors: Excessive negative values (e.g., -50 ms, -54 ms, -48 ms) indicate that some injectors may be defective due to needle seat wear.

- Replacement: It is recommended to replace the implicated injectors to improve engine performance.

Summary of Critical Thresholds:

- First Pressure Level (300 bar): Values below -45 ms (e.g., -60 ms) indicate wear.

- Second Pressure Level (600 bar): Values below -15 ms (e.g., -20 ms) indicate wear.

Important Notes:

- Attention to Sign (Minus): The values are negative, so a more negative value indicates a more severe problem.

- Precise Interpretation: Ensure a thorough understanding of the values and thresholds before making decisions about injector replacement.

This process allows you to correctly diagnose your vehicle’s injectors and take the necessary steps to ensure their proper function.

7. FAQ: Injector Values and VCDS

1. Is it safe to perform injector coding myself?

Injector coding can be risky if not done correctly. Incorrect coding can lead to poor engine performance or even damage. It’s best to seek professional assistance from CAR-CODING.EDU.VN to ensure the coding is done safely and accurately.

2. What is the process for remote support from CAR-CODING.EDU.VN?

Our remote support process involves connecting to your vehicle’s ECU remotely using specialized tools and software. You’ll need a VCDS cable connected to your car and a stable internet connection. Our expert technicians will guide you through the process step-by-step.

3. How much does remote injector coding support cost?

The cost of remote injector coding support varies depending on the complexity of the job and the vehicle model. Contact CAR-CODING.EDU.VN for a personalized quote based on your specific needs.

4. What types of vehicles and features does CAR-CODING.EDU.VN support?

We support a wide range of vehicles, including VW, Audi, Seat, and Skoda. Our services include injector coding, ECU programming, fault code clearing, and activating hidden features.

5. What equipment do I need to use CAR-CODING.EDU.VN’s remote support services?

To use our remote support services, you need a VCDS cable, a laptop with a stable internet connection, and the VCDS software installed. We’ll provide guidance on setting everything up.

6. How can I ensure the safety of my vehicle during remote coding?

Safety is our top priority. Our technicians follow strict protocols to ensure the coding process is safe. We also recommend having a fully charged battery and a stable internet connection to avoid interruptions during the coding process.

7. What are the benefits of coding injectors correctly?

Correctly coding injectors ensures optimal engine performance, improves fuel efficiency, reduces emissions, and prevents potential engine damage.

8. How quickly can CAR-CODING.EDU.VN provide remote support?

We offer prompt remote support services. In many cases, we can start assisting you within a few hours of your request. Contact us to schedule a session.

9. What if something goes wrong during the coding process?

Our expert technicians are trained to handle any issues that may arise during the coding process. We also have backup procedures in place to restore your vehicle’s original settings if necessary.

10. Can CAR-CODING.EDU.VN help with other car coding issues besides injector coding?

Yes, we offer a wide range of car coding services, including ECU programming, fault code clearing, activating hidden features, and more. Contact us to learn more about our services.

8. Need Help? Contact CAR-CODING.EDU.VN Today

Are you struggling with injector coding or other car coding issues? Don’t risk damaging your vehicle with improper coding. Contact CAR-CODING.EDU.VN for expert remote support that is safe, efficient, and reliable. Our experienced technicians can help you resolve complex coding problems and optimize your vehicle’s performance.

Why Choose CAR-CODING.EDU.VN?

- Expertise: Our technicians have extensive knowledge of car coding and ECU programming.

- Safety: We prioritize the safety of your vehicle during the coding process.

- Convenience: Get remote support from the comfort of your own garage.

- Affordable: Our services are competitively priced.

- Comprehensive Support: We offer a wide range of car coding services.

Contact Us Today:

- US Office: 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States

- WhatsApp: +1 (641) 206-8880

- Website: CAR-CODING.EDU.VN

Don’t wait any longer! Reach out to CAR-CODING.EDU.VN now and let our experts assist you with your car coding needs.