Navigating modern car coding can be complex, often requiring expert assistance to ensure safety and effectiveness. CAR-CODING.EDU.VN provides reliable remote support for all your coding needs. Benefit from our expertise in ECU programming and hidden feature activation to enhance your vehicle’s performance.

Contents

- 1. What Does Reading Fuel Pump Pressure With VCDS Involve?

- 1.1 Why Is Reading Fuel Pump Pressure Important?

- 1.2 What Tools Do You Need To Read Fuel Pump Pressure?

- 1.3 How Do You Connect VCDS To Your Audi?

- 2. What Are The Steps To Read Fuel Pump Pressure Using VCDS?

- 2.1 Launching VCDS Software And Selecting The Control Module

- 2.2 Accessing Measuring Blocks Or Advanced Measuring Values

- 2.3 Identifying Relevant Fuel Pressure Parameters

- 2.4 Logging And Graphing Fuel Pressure Data

- 2.5 Interpreting Fuel Pressure Readings

- 3. What Are Common Issues Indicated By Fuel Pressure Readings?

- 3.1 Low Fuel Pressure Symptoms

- 3.2 High Fuel Pressure Symptoms

- 3.3 Potential Causes Of Fuel Pressure Issues

- 4. What Are Steps To Troubleshoot Fuel Pressure Problems?

- 4.1 Verifying Fuel Pump Operation

- 4.2 Inspecting And Replacing The Fuel Filter

- 4.3 Checking The Fuel Pressure Regulator

- 4.4 Testing Fuel Injectors For Leaks Or Blockages

- 4.5 Evaluating Fuel Lines And Connections

- 5. How Can Car-Coding.Edu.Vn Assist With Fuel Pressure Diagnostics?

- 5.1 Remote Diagnostic Support

- 5.2 Ecu Programming And Coding Assistance

- 5.3 Clearing Fault Codes Related To Fuel Pressure

- 5.4 Benefits Of Remote Support

- 6. What Is The Importance Of Accurate Fuel Injector Coding?

- 6.1 How Does Fuel Injector Coding Affect Engine Performance?

- 6.2 What Happens If Fuel Injectors Are Not Coded Correctly?

- 6.3 How To Verify And Update Fuel Injector Coding With VCDS

- 7. What Role Does The Fuel Temperature Sensor Play?

- 7.1 How Does The Fuel Temperature Sensor Work?

- 7.2 What Happens If The Fuel Temperature Sensor Fails?

- 7.3 How To Diagnose A Faulty Fuel Temperature Sensor With VCDS

- 8. What Are Best Practices For Fuel System Maintenance?

- 8.1 Regular Fuel Filter Replacement

- 8.2 Using High-Quality Fuel

- 8.3 Inspecting Fuel Lines And Connections Regularly

- 8.4 Monitoring Fuel Pressure Periodically

- 9. How To Clear Fuel Rail/System Pressure Codes?

- 9.1 Addressing The Underlying Issue

- 9.2 Using VCDS To Clear The Code

- 9.3 Verifying The Repair And Monitoring System

- 10. What Are Some Advanced VCDS Coding Options Related To Fuel Systems?

- 10.1 Adjusting Fuel Injector Parameters

- 10.2 Modifying Fuel Pump Control Settings

- 10.3 Optimizing Fuel Mixture Settings

- 10.4 Risks And Precautions

- FAQ: Reading Fuel Pump Pressure Audi VCDS

1. What Does Reading Fuel Pump Pressure With VCDS Involve?

Reading fuel pump pressure using VCDS (VAG-COM Diagnostic System) involves connecting a diagnostic tool to your Audi to monitor the fuel pressure in real-time, helping to diagnose fuel delivery issues. This process uses VCDS to access live data from the engine control unit (ECU), providing precise pressure readings. Understanding how to interpret these readings is crucial for effective troubleshooting.

1.1 Why Is Reading Fuel Pump Pressure Important?

Reading fuel pump pressure is crucial for diagnosing various engine performance issues related to fuel delivery. Accurate fuel pressure is essential for optimal engine operation.

- Identifying Fuel System Problems: Inadequate fuel pressure can cause poor engine performance, stalling, or difficulty starting.

- Preventing Costly Repairs: Early detection of fuel pressure issues can prevent damage to other components, such as the fuel pump or injectors.

- Ensuring Engine Efficiency: Maintaining proper fuel pressure ensures the engine runs efficiently, optimizing fuel economy and reducing emissions.

1.2 What Tools Do You Need To Read Fuel Pump Pressure?

To accurately read fuel pump pressure on an Audi using VCDS, you will need specific tools and software to interface with the vehicle’s ECU. The right equipment ensures reliable data collection and minimizes the risk of errors during diagnostics.

- VCDS Diagnostic Tool: A genuine VCDS cable and software from Ross-Tech are essential for accessing the vehicle’s diagnostic system.

- Laptop With VCDS Software: A laptop with the VCDS software installed is needed to connect to the vehicle and display the data.

- Vehicle Compatibility: Ensure the VCDS tool is compatible with the specific model and year of your Audi for accurate data retrieval.

1.3 How Do You Connect VCDS To Your Audi?

Connecting VCDS to your Audi involves a few straightforward steps to establish communication with the vehicle’s ECU. Proper connection is crucial for accurate data collection and diagnostics.

- Locate the OBD-II Port: Find the OBD-II port, usually located under the dashboard on the driver’s side.

- Connect the VCDS Cable: Plug the VCDS cable into the OBD-II port.

- Turn on the Ignition: Turn the ignition to the “ON” position without starting the engine.

- Launch the VCDS Software: Open the VCDS software on your laptop.

- Select the Control Module: Choose the engine control module (ECU) from the list of available modules.

- Establish Connection: Test the connection to ensure the VCDS can communicate with the ECU.

2. What Are The Steps To Read Fuel Pump Pressure Using VCDS?

Reading fuel pump pressure using VCDS involves several steps within the VCDS software to access and interpret live data. Follow this detailed procedure for accurate readings.

2.1 Launching VCDS Software And Selecting The Control Module

To begin, launch the VCDS software on your computer and select the appropriate control module to access fuel pressure data.

- Open VCDS Software: Double-click the VCDS icon on your desktop to launch the software.

- Select Control Module: On the main screen, click “Select Control Module.”

- Choose Engine Module: Select the engine control module (usually labeled as “01-Engine”).

- Confirm Connection: Ensure the software connects to the ECU without errors before proceeding.

2.2 Accessing Measuring Blocks Or Advanced Measuring Values

Once connected, navigate to the measuring blocks or advanced measuring values section to find the specific parameters for fuel pressure.

- Navigate to Measuring Blocks: Click on “Measuring Blocks – 08” or “Advanced Measuring Values – 08.” The option may vary based on your VCDS version and vehicle model.

- Identify Fuel Pressure Parameters: Look for parameters related to fuel pressure, such as “Fuel Rail Pressure (specified)” and “Fuel Rail Pressure (actual).”

2.3 Identifying Relevant Fuel Pressure Parameters

Identifying the correct fuel pressure parameters is essential for accurate diagnosis. Select parameters that provide both specified and actual fuel pressure readings.

- Fuel Rail Pressure (Specified): This parameter indicates the fuel pressure the ECU is requesting.

- Fuel Rail Pressure (Actual): This parameter shows the actual fuel pressure measured in the fuel rail.

- Fuel Pump Duty Cycle: This parameter can indicate the pump’s effort to maintain pressure.

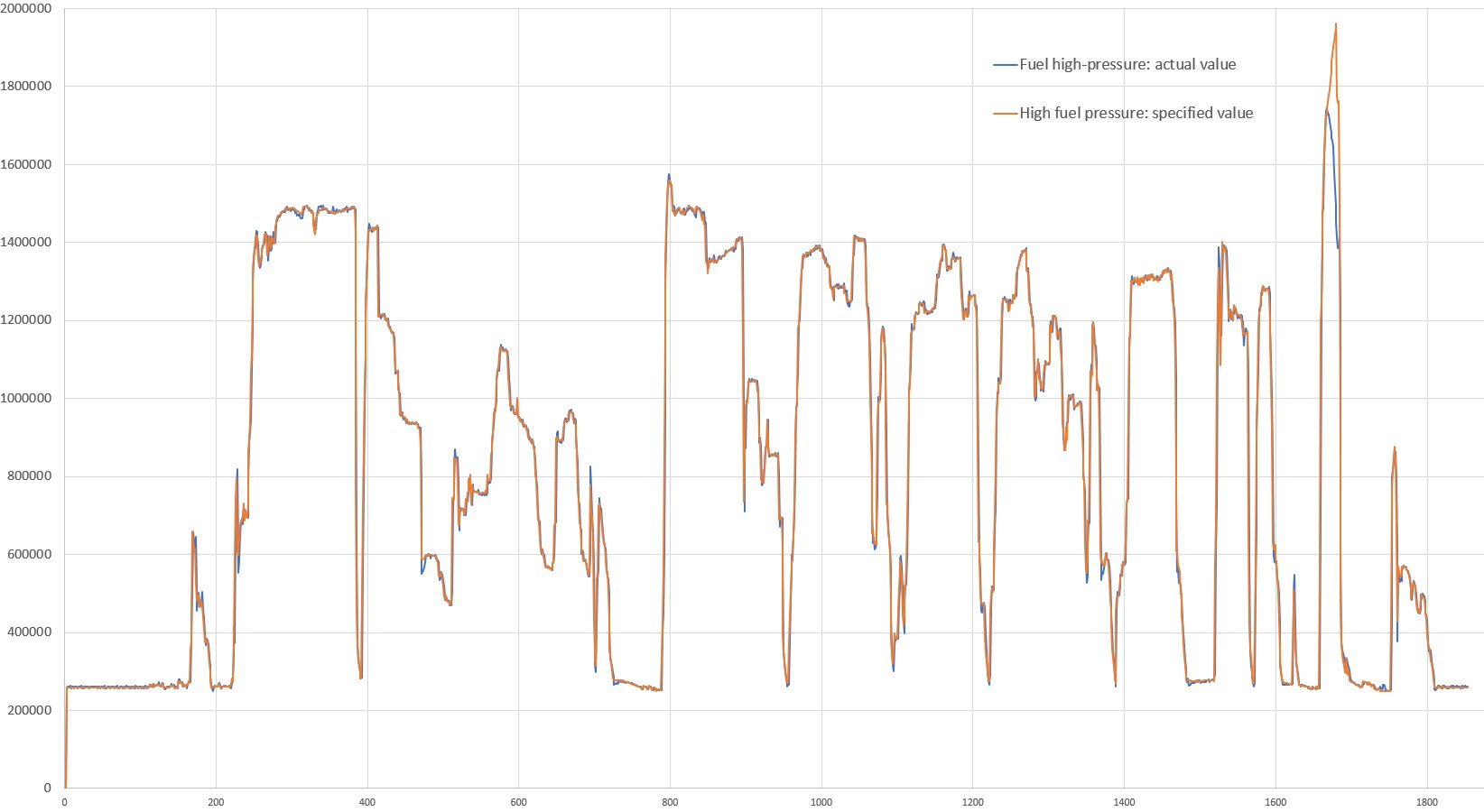

2.4 Logging And Graphing Fuel Pressure Data

Logging and graphing the fuel pressure data allows you to observe how the fuel pressure behaves under different engine loads.

- Start Logging: Click the “Log” button to start recording the data.

- Drive the Vehicle: Drive the vehicle under various conditions (idle, acceleration, cruising) to capture a range of data points.

- Stop Logging: Click the “Stop” button to end the data recording.

- Graph the Data: Use the VCDS software or export the data to a spreadsheet program to create a graph of the fuel pressure over time.

VCDS Fuel Pressure Graph

VCDS Fuel Pressure Graph

2.5 Interpreting Fuel Pressure Readings

Interpreting fuel pressure readings involves comparing the specified and actual values to identify any discrepancies. Understanding these readings is crucial for diagnosing fuel-related issues.

- Normal Operation: The actual fuel pressure should closely match the specified fuel pressure.

- Low Fuel Pressure: If the actual pressure is significantly lower than the specified pressure, it indicates a potential issue with the fuel pump, fuel filter, or fuel pressure regulator.

- High Fuel Pressure: If the actual pressure is significantly higher than the specified pressure, it could indicate a faulty fuel pressure regulator or a blocked fuel return line.

3. What Are Common Issues Indicated By Fuel Pressure Readings?

Fuel pressure readings can indicate a variety of issues within the fuel system. Identifying these issues accurately is crucial for effective troubleshooting and repair.

3.1 Low Fuel Pressure Symptoms

Low fuel pressure can lead to various engine performance issues. Recognizing these symptoms can help diagnose fuel delivery problems early.

- Engine Stalling: The engine may stall, especially under load.

- Difficulty Starting: The vehicle may take longer to start or fail to start at all.

- Poor Acceleration: The engine may lack power during acceleration.

- Rough Idle: The engine may idle roughly or unevenly.

- Check Engine Light: The check engine light may illuminate with codes related to fuel pressure.

3.2 High Fuel Pressure Symptoms

High fuel pressure can also cause engine performance problems. Identifying these symptoms can help pinpoint issues with the fuel pressure regulation system.

- Poor Fuel Economy: The engine may consume more fuel than usual.

- Black Smoke From Exhaust: Excessive fuel can lead to black smoke from the exhaust.

- Engine Hesitation: The engine may hesitate or stumble during acceleration.

- Fuel Odor: A strong fuel odor may be present, indicating a leak or over-fueling.

3.3 Potential Causes Of Fuel Pressure Issues

Several components can cause fuel pressure issues. Diagnosing the root cause requires a systematic approach to identify the faulty part.

- Faulty Fuel Pump: A worn or failing fuel pump may not provide adequate pressure.

- Clogged Fuel Filter: A blocked fuel filter can restrict fuel flow and reduce pressure.

- Failing Fuel Pressure Regulator: A malfunctioning regulator can cause pressure to be too high or too low.

- Leaking Fuel Injectors: Leaking injectors can cause a drop in fuel pressure.

- Damaged Fuel Lines: Damaged or kinked fuel lines can restrict fuel flow.

4. What Are Steps To Troubleshoot Fuel Pressure Problems?

Troubleshooting fuel pressure problems involves a systematic approach to identify and resolve the underlying issues. Follow these steps for effective diagnostics and repair.

4.1 Verifying Fuel Pump Operation

Verifying the fuel pump’s operation is a crucial first step in diagnosing fuel pressure issues. Ensure the pump is receiving power and functioning correctly.

- Listen for Fuel Pump Noise: Turn the ignition to the “ON” position and listen for the fuel pump to prime (a brief buzzing sound).

- Check Fuel Pump Relay: Locate the fuel pump relay and check if it is functioning correctly. You can swap it with a known good relay to test.

- Inspect Fuel Pump Wiring: Check the wiring to the fuel pump for any damage or corrosion.

- Measure Fuel Pump Voltage: Use a multimeter to measure the voltage at the fuel pump connector to ensure it is receiving adequate power.

4.2 Inspecting And Replacing The Fuel Filter

Inspecting and replacing the fuel filter is a simple but essential step in troubleshooting fuel pressure issues. A clogged filter can significantly restrict fuel flow.

- Locate the Fuel Filter: Find the fuel filter, usually located in the fuel line between the fuel tank and the engine.

- Inspect the Filter: Check the filter for any signs of clogging or damage.

- Replace the Filter: If the filter is dirty or suspected of being clogged, replace it with a new one. Ensure you install it in the correct direction.

4.3 Checking The Fuel Pressure Regulator

Checking the fuel pressure regulator is essential for ensuring proper fuel pressure control. A faulty regulator can cause pressure to be too high or too low.

- Locate the Fuel Pressure Regulator: Find the fuel pressure regulator, usually located on the fuel rail.

- Inspect for Leaks: Check the regulator for any signs of leaks.

- Test the Regulator: Use a fuel pressure gauge to test the regulator’s ability to maintain the correct fuel pressure. Compare the reading with the vehicle’s specifications.

4.4 Testing Fuel Injectors For Leaks Or Blockages

Testing fuel injectors for leaks or blockages is crucial for ensuring proper fuel delivery. Faulty injectors can cause fuel pressure issues and poor engine performance.

- Visual Inspection: Inspect the injectors for any signs of leaks or damage.

- Resistance Test: Use a multimeter to measure the resistance of each injector. Compare the readings to the vehicle’s specifications.

- Flow Test: Use a fuel injector cleaning and testing machine to check the flow rate and spray pattern of each injector.

4.5 Evaluating Fuel Lines And Connections

Evaluating fuel lines and connections is essential for identifying any restrictions or leaks in the fuel system. Damaged fuel lines can cause significant fuel pressure issues.

- Visual Inspection: Inspect all fuel lines for any signs of damage, such as cracks, kinks, or corrosion.

- Check Connections: Ensure all fuel line connections are secure and free from leaks.

- Pressure Test: Use a fuel pressure gauge to perform a pressure test on the fuel lines to check for leaks.

5. How Can Car-Coding.Edu.Vn Assist With Fuel Pressure Diagnostics?

CAR-CODING.EDU.VN offers expert remote support to assist with fuel pressure diagnostics and troubleshooting. Our services provide timely and effective solutions for complex fuel system issues.

5.1 Remote Diagnostic Support

Our remote diagnostic support provides real-time assistance in diagnosing fuel pressure issues. We can guide you through the process and interpret the data to identify the problem.

- Real-Time Assistance: Connect with our experts for immediate help with fuel pressure diagnostics.

- Data Interpretation: We can analyze your VCDS data to pinpoint the source of the problem.

- Step-by-Step Guidance: Receive step-by-step instructions for troubleshooting and repair.

5.2 Ecu Programming And Coding Assistance

CAR-CODING.EDU.VN offers ECU programming and coding assistance to ensure your vehicle’s fuel system operates correctly. Proper coding can resolve issues related to fuel delivery and engine performance.

- Fuel Injector Coding: Ensure your fuel injectors are correctly coded to optimize fuel delivery.

- Fuel Pump Calibration: Calibrate the fuel pump settings for optimal performance.

- ECU Updates: Receive the latest ECU updates to improve fuel efficiency and performance.

5.3 Clearing Fault Codes Related To Fuel Pressure

We can help clear fault codes related to fuel pressure to ensure your vehicle’s system is functioning correctly. Removing these codes is essential for accurate diagnostics and preventing future issues.

- Fault Code Clearing: Clear any stored fault codes related to fuel pressure.

- Diagnostic Assistance: Help identify the root cause of the fault codes.

- Preventative Measures: Guidance on preventing future fuel pressure issues.

5.4 Benefits Of Remote Support

Remote support from CAR-CODING.EDU.VN offers numerous benefits, including convenience, expertise, and cost savings. Our remote services provide efficient solutions without the need for on-site visits.

- Convenience: Receive expert support from the comfort of your own garage.

- Expertise: Access our team of experienced automotive technicians.

- Cost Savings: Avoid the expense of taking your vehicle to a shop.

- Time Savings: Resolve issues quickly with our real-time support.

- Wide Range of Support: We support a wide range of Audi models and fuel system configurations.

6. What Is The Importance Of Accurate Fuel Injector Coding?

Accurate fuel injector coding is crucial for optimal engine performance, fuel efficiency, and emissions control. Correct coding ensures the ECU can precisely control each injector.

6.1 How Does Fuel Injector Coding Affect Engine Performance?

Fuel injector coding directly affects engine performance by ensuring each injector delivers the correct amount of fuel.

- Optimized Fuel Delivery: Accurate coding ensures each injector delivers the precise amount of fuel required for optimal combustion.

- Improved Engine Smoothness: Correctly coded injectors contribute to smoother engine operation and reduced vibrations.

- Enhanced Power Output: Proper fuel delivery results in improved power output and throttle response.

6.2 What Happens If Fuel Injectors Are Not Coded Correctly?

If fuel injectors are not coded correctly, it can lead to various engine performance issues and potential damage.

- Poor Fuel Economy: Incorrect coding can result in over-fueling or under-fueling, leading to reduced fuel economy.

- Increased Emissions: Inaccurate fuel delivery can increase harmful emissions.

- Engine Misfires: Mismatched injector coding can cause engine misfires and rough running.

- Catalytic Converter Damage: Over-fueling can damage the catalytic converter.

6.3 How To Verify And Update Fuel Injector Coding With VCDS

Verifying and updating fuel injector coding with VCDS is a straightforward process that ensures each injector is correctly configured.

- Connect VCDS: Connect the VCDS tool to your Audi and launch the software.

- Select Engine Control Module: Choose the engine control module from the list of available modules.

- Access Adaptation: Navigate to the “Adaptation – 10” function.

- Select Injector Coding Channels: Choose the channels corresponding to each injector (usually channels 71-76).

- Read Current Values: Read the current coding values for each injector.

- Enter New Values: If necessary, enter the correct coding values for each injector. These values are typically found on the injector itself.

- Save Changes: Save the changes and verify that the new coding values have been successfully applied.

7. What Role Does The Fuel Temperature Sensor Play?

The fuel temperature sensor plays a crucial role in the fuel system by providing the ECU with information needed to adjust fuel delivery based on fuel temperature.

7.1 How Does The Fuel Temperature Sensor Work?

The fuel temperature sensor monitors the temperature of the fuel and sends this information to the ECU.

- Temperature Monitoring: The sensor measures the fuel temperature and converts it into an electrical signal.

- Data Transmission: The signal is sent to the ECU, which uses this information to adjust fuel delivery parameters.

- Fuel Mixture Adjustment: The ECU adjusts the fuel mixture to ensure optimal combustion based on the fuel temperature.

7.2 What Happens If The Fuel Temperature Sensor Fails?

If the fuel temperature sensor fails, it can lead to inaccurate fuel delivery and various engine performance issues.

- Incorrect Fuel Mixture: A faulty sensor can cause the ECU to use an incorrect fuel mixture, leading to poor performance.

- Reduced Fuel Economy: Inaccurate fuel delivery can reduce fuel economy.

- Engine Stalling: The engine may stall, especially in extreme temperatures.

- Check Engine Light: The check engine light may illuminate with codes related to the fuel temperature sensor.

7.3 How To Diagnose A Faulty Fuel Temperature Sensor With VCDS

Diagnosing a faulty fuel temperature sensor with VCDS involves checking the sensor’s readings and looking for any fault codes.

- Connect VCDS: Connect the VCDS tool to your Audi and launch the software.

- Select Engine Control Module: Choose the engine control module from the list of available modules.

- Access Measuring Blocks: Navigate to the “Measuring Blocks – 08” function.

- Identify Fuel Temperature Parameter: Look for the parameter related to fuel temperature.

- Read Sensor Value: Read the current value of the fuel temperature sensor. Compare the reading to the expected value based on the ambient temperature.

- Check Fault Codes: Check for any fault codes related to the fuel temperature sensor.

8. What Are Best Practices For Fuel System Maintenance?

Following best practices for fuel system maintenance can help prevent fuel pressure issues and ensure optimal engine performance.

8.1 Regular Fuel Filter Replacement

Regularly replacing the fuel filter is essential for maintaining proper fuel flow and preventing fuel pressure issues.

- Recommended Intervals: Follow the manufacturer’s recommended intervals for fuel filter replacement.

- Filter Quality: Use a high-quality fuel filter to ensure optimal filtration.

- Inspection: Inspect the fuel filter regularly for any signs of clogging or damage.

8.2 Using High-Quality Fuel

Using high-quality fuel can help prevent fuel system issues and maintain optimal engine performance.

- Octane Rating: Use the correct octane rating fuel as specified by the manufacturer.

- Fuel Additives: Consider using fuel additives to help clean fuel injectors and prevent deposits.

- Avoid Contaminated Fuel: Avoid using fuel from unreliable sources to prevent contamination.

8.3 Inspecting Fuel Lines And Connections Regularly

Regularly inspecting fuel lines and connections can help identify and address any potential leaks or damage.

- Visual Inspection: Inspect fuel lines and connections for any signs of cracks, kinks, or corrosion.

- Tighten Connections: Ensure all fuel line connections are secure and free from leaks.

- Replace Damaged Lines: Replace any damaged fuel lines to prevent fuel leaks and pressure issues.

8.4 Monitoring Fuel Pressure Periodically

Periodically monitoring fuel pressure can help detect potential issues early and prevent more significant problems.

- VCDS Monitoring: Use VCDS to monitor fuel pressure readings regularly.

- Fuel Pressure Gauge: Consider using a fuel pressure gauge to monitor fuel pressure directly.

- Early Detection: Early detection of fuel pressure issues can prevent damage to other components.

9. How To Clear Fuel Rail/System Pressure Codes?

Clearing fuel rail/system pressure codes requires addressing the underlying issue causing the code and then using a diagnostic tool to clear the code from the ECU.

9.1 Addressing The Underlying Issue

Before clearing the code, it’s crucial to identify and resolve the root cause of the fuel pressure issue.

- Diagnose the Problem: Use VCDS or other diagnostic tools to pinpoint the cause of the low fuel pressure.

- Repair or Replace Components: Repair or replace any faulty components, such as the fuel pump, fuel filter, or fuel pressure regulator.

- Verify Repair: After the repair, verify that the fuel pressure is within the specified range.

9.2 Using VCDS To Clear The Code

Once the underlying issue is resolved, use VCDS to clear the fuel rail/system pressure code from the ECU.

- Connect VCDS: Connect the VCDS tool to your Audi and launch the software.

- Select Engine Control Module: Choose the engine control module from the list of available modules.

- Access Fault Codes: Navigate to the “Fault Codes – 02” function.

- Clear Fault Codes: Click the “Clear Codes – 05” button to clear the stored fault codes.

- Verify Code Clearing: Verify that the fuel rail/system pressure code has been successfully cleared.

9.3 Verifying The Repair And Monitoring System

After clearing the code, it’s essential to verify the repair and monitor the system to ensure the issue does not return.

- Test Drive: Perform a test drive to ensure the engine is running smoothly and the fuel pressure is stable.

- Monitor Fuel Pressure: Use VCDS to monitor fuel pressure readings and ensure they remain within the specified range.

- Check For Recurring Codes: Check for any recurring fault codes related to fuel pressure.

10. What Are Some Advanced VCDS Coding Options Related To Fuel Systems?

Advanced VCDS coding options related to fuel systems can optimize fuel delivery, improve engine performance, and enhance fuel efficiency.

10.1 Adjusting Fuel Injector Parameters

Adjusting fuel injector parameters can fine-tune fuel delivery for optimal engine performance.

- Injector Calibration: Calibrate fuel injectors to ensure precise fuel delivery.

- Injection Timing: Adjust injection timing to optimize combustion.

- Fuel Cutoff Settings: Modify fuel cutoff settings to improve fuel efficiency.

10.2 Modifying Fuel Pump Control Settings

Modifying fuel pump control settings can improve fuel pump performance and prevent fuel pressure issues.

- Pump Voltage: Adjust pump voltage to optimize fuel delivery.

- Duty Cycle: Modify the fuel pump duty cycle to improve performance.

- Pump Activation Thresholds: Adjust pump activation thresholds to prevent fuel starvation.

10.3 Optimizing Fuel Mixture Settings

Optimizing fuel mixture settings can improve engine performance and reduce emissions.

- Air-Fuel Ratio: Adjust the air-fuel ratio to optimize combustion.

- Lambda Control: Fine-tune lambda control settings to reduce emissions.

- Fuel Trim Adjustments: Make fuel trim adjustments to compensate for engine wear.

10.4 Risks And Precautions

When performing advanced VCDS coding, it’s crucial to be aware of the risks and take necessary precautions.

- Back Up Original Settings: Always back up the original coding settings before making any changes.

- Use Reliable Information: Use reliable coding information from trusted sources.

- Follow Instructions Carefully: Follow coding instructions carefully to avoid errors.

- Seek Expert Assistance: If you’re unsure about any coding procedure, seek expert assistance from CAR-CODING.EDU.VN.

FAQ: Reading Fuel Pump Pressure Audi VCDS

1. Is It Safe To Read Fuel Pump Pressure With VCDS?

Yes, it is generally safe to read fuel pump pressure with VCDS as long as you follow the proper procedures and use a genuine VCDS tool.

2. What Is The Process For Remote Assistance From Car-Coding.Edu.Vn?

The remote assistance process involves connecting with our experts, who will guide you through the diagnostic and coding procedures using VCDS.

3. How Much Does Remote Support Cost?

The cost of remote support varies depending on the complexity of the issue. Contact us for a personalized quote.

4. Which Audi Models Are Supported For Fuel Pressure Diagnostics?

We support a wide range of Audi models for fuel pressure diagnostics, including A3, A4, A6, Q5, and Q7.

5. What Types Of Fuel System Issues Can Be Resolved With Remote Coding Support?

Remote coding support can resolve issues such as fuel injector coding problems, fuel pump calibration issues, and ECU-related fuel delivery problems.

6. What Equipment Is Needed On My End To Receive Remote Support?

You will need a genuine VCDS tool, a laptop with VCDS software installed, and a stable internet connection.

7. How Quickly Can I Get Remote Support?

We offer both immediate and scheduled remote support options. Contact us to arrange the most convenient time.

8. Can Remote Coding Damage My Car’s ECU?

When performed correctly by experienced technicians, remote coding is safe and will not damage your car’s ECU. Always ensure you are working with trusted professionals.

9. What Are The Benefits Of Choosing Car-Coding.Edu.Vn For Remote Support?

The benefits include expert technicians, cost savings, convenience, and a wide range of support for various Audi models and fuel system configurations.

10. Are There Any Risks Involved In Adjusting Fuel System Parameters?

Yes, there are risks involved in adjusting fuel system parameters. Always back up original settings, use reliable information, and follow instructions carefully.

Addressing fuel pressure issues in your Audi requires a thorough understanding of the fuel system and the proper use of diagnostic tools like VCDS. CAR-CODING.EDU.VN offers expert remote support to guide you through the process, ensuring accurate diagnostics and effective solutions. Whether you need help interpreting fuel pressure readings, coding fuel injectors, or clearing fault codes, our team is ready to assist you. Contact us today at +1 (641) 206-8880 or visit our website at CAR-CODING.EDU.VN for more information and support. Our office is located at 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States. Get the expert assistance you need to keep your Audi running smoothly and efficiently.

Don’t let fuel pressure problems keep you off the road. Reach out to CAR-CODING.EDU.VN now for immediate remote support and get your Audi back in top condition. Our expert technicians are standing by to provide the solutions you need quickly and effectively.