Decoding your vehicle’s performance data is achievable with the correct tools and knowledge. Understanding How To Read A Vcds Log, crucial for diagnosing issues and optimizing performance, can be simplified with guidance from CAR-CODING.EDU.VN. Our remote automotive coding support provides expert assistance, ensuring you can accurately interpret logs and make informed decisions. Whether you’re analyzing engine performance, diagnosing fault codes, or activating hidden features, our team is here to help with remote automotive coding support.

Contents

- 1. What is a VCDS Log and Why is it Important?

- 1.1 Understanding VCDS

- 1.2 The Role of Logging in Vehicle Diagnostics

- 1.3 Why VCDS Logs Matter

- 2. Essential Tools and Software

- 2.1 VCDS Software and Interface Cable

- 2.2 Computer Requirements

- 2.3 Additional Software for Log Analysis

- 3. Step-by-Step Guide to Capturing a VCDS Log

- 3.1 Connecting to the Vehicle

- 3.2 Checking for Fault Codes

- 3.3 Selecting the Control Module

- 3.4 Accessing Advanced Measuring Values

- 3.5 Selecting Parameters for Logging

- 3.6 Saving the Parameter List

- 3.7 Configuring Logging Options

- 3.8 Starting and Stopping the Logging Process

- 4. Understanding Key Parameters in a VCDS Log

- 4.1 Engine Speed (RPM)

- 4.2 Accelerator Pedal Position

- 4.3 Intake Air Temperature (IAT)

- 4.4 Mass Air Flow (MAF)

- 4.5 Ignition Timing

- 4.6 Knock Retard

- 4.7 Boost Pressure

- 4.8 Lambda/Air-Fuel Ratio (AFR)

- 4.9 Fuel Trims

- 5. Interpreting VCDS Logs: A Detailed Approach

- 5.1 Opening and Formatting the Log File

- 5.2 Calculating Derived Values

- 5.3 Identifying Anomalies and Potential Issues

- 5.4 Using Graphs to Visualize Data

- 5.5 Seeking Expert Assistance

- 6. Common Logging Scenarios and Troubleshooting

- 6.1 Diagnosing Performance Issues

- 6.2 Optimizing Fuel Efficiency

- 6.3 Troubleshooting Logging Problems

- 7. Advanced Logging Techniques

- 7.1 Logging Specific Modules

- 7.2 Using Custom Parameter Groups

- 7.3 Analyzing Data with Third-Party Tools

- 8. Examples of Coding Adjustments Based on Log Analysis

- 8.1 Adjusting Boost Levels

- 8.2 Fine-Tuning Fuel Injection

- 8.3 Modifying Ignition Timing

- 8.4 Optimizing Transmission Shift Points

- 8.5 Enabling/Disabling Features Based on Data

- 9. The Importance of Professional Assistance

- 9.1 Expertise and Experience

- 9.2 Access to Advanced Tools

- 9.3 Safe and Reliable Coding

- 9.4 Accurate Diagnostics

- 9.5 Remote Support Benefits

- 10. Frequently Asked Questions (FAQ) About VCDS Logging

- 10.1 Is it Safe to Perform Coding Adjustments?

- 10.2 What is the Process for Remote Support?

- 10.3 How Much Does Remote Coding Support Cost?

- 10.4 What Types of Vehicles/Features are Supported?

- 10.5 What Equipment is Required on the Technician’s End?

- 10.6 How Can I Ensure the Safety of My Vehicle During Coding?

- 10.7 What Can I Do If Something Goes Wrong During Coding?

- 10.8 What Should I Do Before Starting Coding?

- 10.9 Is it Possible to Damage My Car’s ECU While Coding?

- 10.10 Is There a Way to Revert Coding Changes?

- Take Action Now

1. What is a VCDS Log and Why is it Important?

A VCDS (VAG-COM Diagnostic System) log is a data recording of various parameters from your vehicle’s control modules, and it’s important because it provides insights into your car’s operation, helping diagnose issues and optimize performance. Think of it as a detailed health report for your car.

1.1 Understanding VCDS

VCDS, developed by Ross-Tech, is a diagnostic tool used primarily for Volkswagen Audi Group (VAG) vehicles, including Volkswagen, Audi, Škoda, and SEAT. It allows users to access and diagnose various control modules within the vehicle, such as the engine, transmission, ABS, and airbags. It also enables users to perform coding, adaptations, and other advanced functions. VCDS is a Windows-based software that connects to the vehicle via a special interface cable that plugs into the OBD-II port.

1.2 The Role of Logging in Vehicle Diagnostics

Logging is the process of recording data from the vehicle’s control modules over a period of time. This data can then be analyzed to identify potential issues, monitor performance, and optimize settings. Logging is particularly useful for diagnosing intermittent problems that may not be readily apparent during a static inspection.

1.3 Why VCDS Logs Matter

VCDS logs are important for several reasons:

- Diagnostic Accuracy: They provide a detailed record of vehicle behavior, aiding in accurate diagnosis of faults.

- Performance Monitoring: They allow you to monitor the performance of your engine and other systems under various conditions.

- Tuning Optimization: They help you fine-tune your vehicle’s performance by analyzing data related to boost, fuel, and timing.

- Problem Prevention: They enable you to identify potential issues before they become major problems.

2. Essential Tools and Software

To effectively read and interpret VCDS logs, you need the right tools and software. The core components include the VCDS software, a compatible interface cable, and a computer running Windows.

2.1 VCDS Software and Interface Cable

The VCDS software is the primary tool for accessing and logging data from your vehicle’s control modules. It requires a special interface cable that connects your computer to the vehicle’s OBD-II port. Ross-Tech offers various cable options, including the HEX-V2 and the older HEX+CAN. Make sure to purchase a genuine Ross-Tech cable to ensure compatibility and access to all features.

2.2 Computer Requirements

VCDS is Windows-based software, so you’ll need a computer running Windows XP, Vista, 7, 8, 10, or 11. The software has minimal hardware requirements, so most modern laptops or desktops should work fine. It’s recommended to have a stable internet connection for software updates and accessing online resources.

2.3 Additional Software for Log Analysis

While VCDS can display logged data, it’s often helpful to use additional software for more in-depth analysis. Microsoft Excel or similar spreadsheet programs can be used to open and analyze the CSV files generated by VCDS. These programs allow you to create graphs, charts, and perform calculations on the data.

3. Step-by-Step Guide to Capturing a VCDS Log

Capturing a VCDS log involves several steps, from connecting the cable to selecting the right parameters. Follow these steps to ensure you get accurate and useful data.

3.1 Connecting to the Vehicle

- Plug in the Cable: Turn off the vehicle. Locate the OBD-II port, usually found under the dashboard on the driver’s side. Plug the Ross-Tech VCDS cable into the OBD-II port.

- Turn on the Ignition: Turn the ignition to the “ON” position, but do not start the engine.

- Launch VCDS: Open the VCDS software on your computer.

Connecting the VCDS cable to the OBDII port

Connecting the VCDS cable to the OBDII port

3.2 Checking for Fault Codes

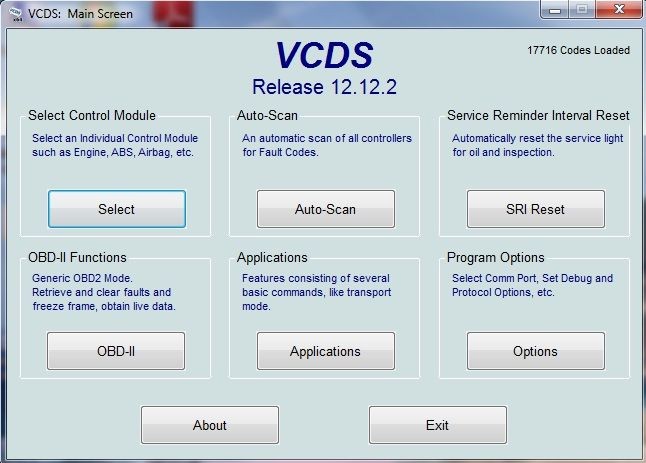

- Run an Auto-Scan: On the VCDS main menu, click the “Auto-Scan” button.

- Start the Scan: In the Auto-Scan section, click the “Start” button to scan for fault codes in all modules. This process may take a few minutes.

- Save and Clear Faults: If any faults are found, save the scan results (copy/paste, save, or print). Then, click the “Clear all DTC’s” button to clear the fault codes.

- Close Auto-Scan: Click “Close” to return to the main menu.

3.3 Selecting the Control Module

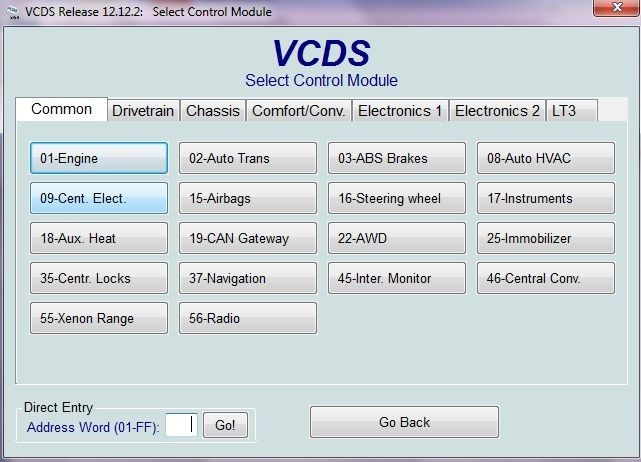

- Select Control Module: On the main menu, click the “Select” button under “Select Control Module”.

- Choose the Engine Module: Under the “Common” tab, click the “01-Engine” module button.

Selecting the engine control module in VCDS

Selecting the engine control module in VCDS

3.4 Accessing Advanced Measuring Values

- Adv. Meas. Values: In the Engine Controller module, click the “Adv. Meas. Values” button to access the logging section.

3.5 Selecting Parameters for Logging

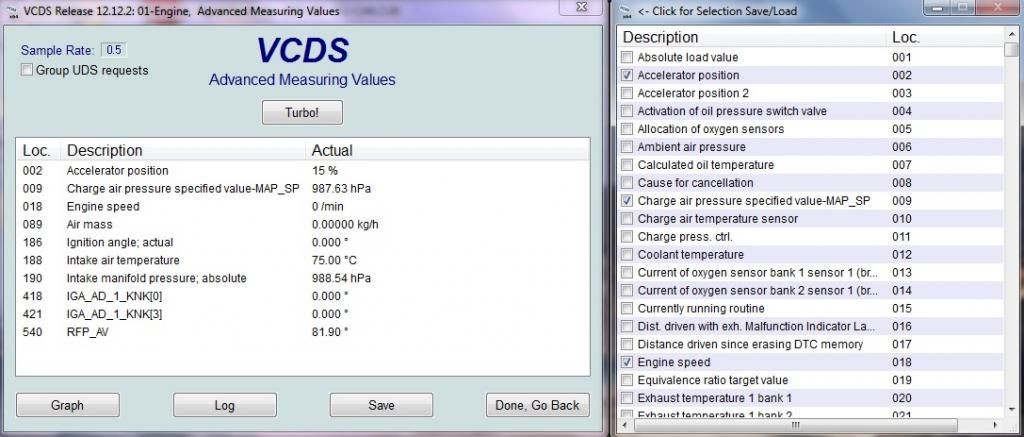

-

Ambient Air Pressure: Select the “Ambient Air Pressure” value from the parameter list. Note the displayed value for later use, then uncheck the box.

-

Choose Logging Parameters: Select the parameters you want to log. VCDS allows a maximum of 12 parameters, or 10 if using grouping.

- Recommended Parameters for Performance Logging (B8/B8.5):

- Accelerator position (%)

- Charge air pressure specified value (hPa)

- Engine speed (RPM)

- Air mass (kg/h)

- Ignition angle; actual (degrees)

- Intake air temperature (degrees C)

- Intake manifold pressure; absolute (hPa)

- IGA_AD_KNK[x] (knock detection/timing pulled on cylinders 1-4)

- RFP_AV (bypass valve %)

- Recommended Parameters for Performance Logging (B8/B8.5):

Selecting logging fields in VCDS

Selecting logging fields in VCDS

3.6 Saving the Parameter List

- Save Parameter List: Save the parameter list for future use by clicking the “VCDS” icon in the top-left corner. Name the file “performance” or similar.

3.7 Configuring Logging Options

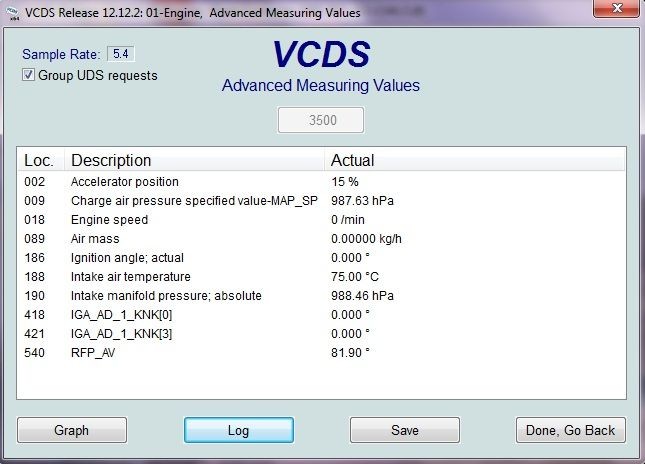

- Turbo Mode and Group UDS Requests: This is crucial for accurate logs. Click the “Turbo” button, and check the “Group UDS requests” box at the top of the screen. This speeds up logging and groups all fields to the same timestamp.

Configuring VCDS logging options

Configuring VCDS logging options

3.8 Starting and Stopping the Logging Process

- Initiate Logging Session: Click the “Log” button to initiate the logging session.

- Start Logging: Click the “Start” button to begin the actual logging process.

- Notes for Logging:

- Perform logging in a safe, controlled environment where you can reach 85-90 MPH.

- Capture a full 3rd gear pull (3000 RPM to 7000 RPM) at a minimum.

- Turn off A/C and radio, close windows, set car to dynamic mode (if available), and turn off traction/ASR.

- Log on a flat surface and in similar conditions each time for accurate data comparison.

- Notes for Logging:

- Stop Logging: Once you have captured the necessary logs, click the “Stop” button to stop the logging process, and then click “Done, close”. The logs will be saved as a .CSV file in the Ross-Tech/VCDS/Logs folder.

4. Understanding Key Parameters in a VCDS Log

Interpreting a VCDS log requires knowledge of the key parameters and what they indicate about your vehicle’s performance. Here are some of the most important parameters to monitor.

4.1 Engine Speed (RPM)

Engine speed, measured in revolutions per minute (RPM), indicates how fast the engine’s crankshaft is rotating. Monitoring RPM is crucial for understanding engine load and performance.

4.2 Accelerator Pedal Position

This parameter indicates the percentage of throttle opening. It reflects how much the driver is demanding from the engine.

4.3 Intake Air Temperature (IAT)

Intake Air Temperature (IAT) is measured in degrees Celsius or Fahrenheit and reflects the temperature of the air entering the engine. High IAT can reduce engine performance and increase the risk of knocking.

4.4 Mass Air Flow (MAF)

Mass Air Flow (MAF) measures the amount of air entering the engine, usually in kilograms per hour (kg/h) or grams per second (g/s). This parameter is important for calculating the air-fuel ratio and ensuring proper combustion.

4.5 Ignition Timing

Ignition timing, measured in degrees before top dead center (BTDC), indicates when the spark plugs fire in relation to the piston’s position. Adjusting ignition timing can improve engine power and efficiency, but excessive advance can lead to knocking.

4.6 Knock Retard

Knock retard, measured in degrees, indicates how much the ECU is retarding the ignition timing due to detected engine knock. High knock retard values suggest potential issues with fuel quality, engine temperature, or other factors.

4.7 Boost Pressure

Boost pressure, measured in hectopascals (hPa) or pounds per square inch (PSI), indicates the amount of pressure generated by the turbocharger. Monitoring boost pressure is essential for ensuring the turbocharger is performing as expected. Note that VCDS often displays boost as an absolute value (specified boost + ambient air pressure), requiring calculation to determine actual boost.

4.8 Lambda/Air-Fuel Ratio (AFR)

Lambda or Air-Fuel Ratio (AFR) is crucial for understanding the engine’s combustion efficiency. It represents the ratio of air to fuel in the combustion chamber. Optimal AFR ensures efficient combustion and minimizes emissions.

4.9 Fuel Trims

Fuel trims indicate the adjustments the ECU is making to the fuel mixture to maintain the desired AFR. Short-term fuel trims (STFT) reflect immediate adjustments, while long-term fuel trims (LTFT) indicate more sustained deviations.

5. Interpreting VCDS Logs: A Detailed Approach

Interpreting VCDS logs involves analyzing the data to identify patterns, anomalies, and potential issues. This section provides a detailed approach to log analysis, including calculating derived values and identifying common problems.

5.1 Opening and Formatting the Log File

- Locate the Log File: Navigate to the Ross-Tech/VCDS/Logs folder on your computer and find the .CSV file you saved.

- Open with Excel: Open the .CSV file with Microsoft Excel or a similar spreadsheet program.

- Format the Data: Adjust the column widths for better readability. You may also want to freeze the top row to keep the parameter names visible while scrolling.

5.2 Calculating Derived Values

In many cases, the raw data in a VCDS log needs to be processed to derive meaningful values. Here are a few examples:

- Actual Boost Pressure: Subtract the ambient air pressure (recorded earlier) from the intake manifold pressure (absolute) to get the actual boost pressure.

- Air-Fuel Ratio (AFR): Use the provided table to convert Lambda values to AFR.

- Injector Duty Cycle (IDC): Calculate the injector duty cycle using the formula: (RPM x IPW)/300 = IDC.

5.3 Identifying Anomalies and Potential Issues

- Boost Deviations: Compare the specified boost pressure to the actual boost pressure. Significant deviations may indicate a boost leak, faulty diverter valve, or other turbocharger-related issues.

- Knock Retard: Monitor the knock retard values. High values may indicate issues with fuel quality, excessive engine temperature, or other factors that could lead to engine damage.

- Fuel Trim Deviations: Analyze the short-term and long-term fuel trims. Large deviations may indicate vacuum leaks, faulty MAF sensor, or fuel delivery problems.

- Misfires: Check for misfires on individual cylinders. Frequent misfires may indicate issues with spark plugs, ignition coils, fuel injectors, or compression.

- Lambda/AFR Imbalances: Ensure the actual Lambda/AFR values are close to the specified values. Significant imbalances may indicate fueling issues or problems with the oxygen sensors.

5.4 Using Graphs to Visualize Data

Creating graphs can help visualize trends and anomalies in the data. Here are a few examples of useful graphs:

- Boost Pressure vs. RPM: This graph can help identify boost leaks or turbocharger performance issues.

- Ignition Timing vs. RPM: This graph can reveal timing pull due to knock or other factors.

- Air-Fuel Ratio vs. RPM: This graph can help identify fueling issues or lean/rich conditions.

5.5 Seeking Expert Assistance

If you’re unsure about interpreting your VCDS logs, don’t hesitate to seek assistance from experts at CAR-CODING.EDU.VN. Our experienced technicians can analyze your logs and provide valuable insights and recommendations.

6. Common Logging Scenarios and Troubleshooting

VCDS logs are useful in various scenarios, from diagnosing performance issues to optimizing fuel efficiency. This section covers common logging scenarios and provides troubleshooting tips.

6.1 Diagnosing Performance Issues

When diagnosing performance issues, it’s important to log relevant parameters based on the symptoms you’re experiencing. For example:

- Loss of Power: Log boost pressure, MAF, IAT, and ignition timing to identify potential issues with the turbocharger, air intake, or ignition system.

- Poor Fuel Economy: Log AFR, fuel trims, and O2 sensor data to identify potential issues with fuel delivery or combustion efficiency.

- Engine Misfires: Log misfire counts for each cylinder to identify potential issues with spark plugs, ignition coils, or fuel injectors.

6.2 Optimizing Fuel Efficiency

To optimize fuel efficiency, log parameters related to fuel consumption and combustion efficiency:

- AFR: Monitor AFR to ensure it’s within the optimal range for fuel efficiency (typically around 14.7:1 for gasoline engines).

- Fuel Trims: Monitor fuel trims to identify potential issues with fuel delivery or vacuum leaks.

- O2 Sensor Data: Monitor O2 sensor data to ensure the sensors are functioning properly and providing accurate feedback to the ECU.

6.3 Troubleshooting Logging Problems

If you encounter issues while logging, here are a few troubleshooting tips:

- Communication Errors: Ensure the VCDS cable is properly connected and the ignition is turned on. Try restarting the VCDS software or your computer.

- Low Resolution: If you’re experiencing low resolution with the latest version of VCDS, try adjusting the Block Int and Char Int parameters as recommended by Ross-Tech.

- Missing Parameters: If certain parameters are missing from the list, ensure you’ve selected the correct control module and that the parameters are supported by your vehicle.

7. Advanced Logging Techniques

For more advanced users, there are several advanced logging techniques that can provide even greater insights into vehicle performance.

7.1 Logging Specific Modules

In addition to the engine module, VCDS allows you to log data from other control modules, such as the transmission, ABS, and airbags. This can be useful for diagnosing issues with these systems.

7.2 Using Custom Parameter Groups

VCDS allows you to create custom parameter groups to log specific combinations of parameters that are relevant to your needs. This can help streamline the logging process and ensure you’re capturing the most important data.

7.3 Analyzing Data with Third-Party Tools

There are several third-party tools available that can help you analyze VCDS logs more effectively. These tools often offer advanced features, such as automated anomaly detection, data visualization, and performance analysis.

8. Examples of Coding Adjustments Based on Log Analysis

VCDS logs not only help diagnose problems but can also inform coding adjustments to optimize vehicle performance and personalize features. Here are a few examples:

8.1 Adjusting Boost Levels

Aftermarket tunes often aim to increase boost levels for enhanced performance. Analyzing VCDS logs can reveal if the actual boost matches the specified boost. If there’s a discrepancy, adjustments may be needed to the tune or hardware components.

8.2 Fine-Tuning Fuel Injection

Logs showing AFR deviations can guide adjustments to fuel injection settings. Whether it’s modifying injector pulse width or adjusting fuel pressure, the goal is to maintain an optimal AFR for power and efficiency.

8.3 Modifying Ignition Timing

If logs indicate excessive knock retard, ignition timing can be adjusted to reduce the risk of engine damage. This involves carefully reducing the advance to prevent knocking while maintaining optimal performance.

8.4 Optimizing Transmission Shift Points

For vehicles with automatic transmissions, logs can reveal if the shift points are optimal for the driver’s style and driving conditions. Coding adjustments can then be made to fine-tune these shift points.

8.5 Enabling/Disabling Features Based on Data

Certain features, like start-stop systems, may not be desirable for all drivers. VCDS logs showing the impact of these features on fuel consumption can inform decisions to enable or disable them through coding.

9. The Importance of Professional Assistance

While this guide provides a comprehensive overview of how to read a VCDS log, interpreting the data and making appropriate adjustments can be complex. Professional assistance is invaluable for several reasons:

9.1 Expertise and Experience

Professionals have extensive experience interpreting VCDS logs and diagnosing vehicle issues. Their expertise can save you time and prevent costly mistakes.

9.2 Access to Advanced Tools

Professionals often have access to advanced diagnostic tools and software that can provide even greater insights into vehicle performance.

9.3 Safe and Reliable Coding

Coding adjustments can have a significant impact on vehicle performance and safety. Professionals can ensure that coding is performed safely and reliably.

9.4 Accurate Diagnostics

Misinterpreting VCDS logs can lead to incorrect diagnoses and unnecessary repairs. Professionals can provide accurate diagnoses and recommend the most appropriate solutions.

9.5 Remote Support Benefits

CAR-CODING.EDU.VN offers remote support, providing expertise from the comfort of your garage. Our remote automotive coding support ensures you get accurate diagnostics and coding adjustments without needing to visit a shop.

10. Frequently Asked Questions (FAQ) About VCDS Logging

Here are some frequently asked questions about VCDS logging to help you further understand the process.

10.1 Is it Safe to Perform Coding Adjustments?

When performed correctly by knowledgeable professionals, coding adjustments are generally safe. However, incorrect coding can lead to unexpected behavior or even damage to the vehicle’s control modules. It’s advisable to seek professional help to ensure a safe and reliable coding process. CAR-CODING.EDU.VN offers remote support for safe and precise coding adjustments.

10.2 What is the Process for Remote Support?

The process for remote support typically involves connecting your computer to the vehicle using a VCDS cable, then granting remote access to a technician who can analyze the logs and make necessary coding adjustments.

10.3 How Much Does Remote Coding Support Cost?

The cost of remote coding support varies depending on the complexity of the task and the provider’s rates. Contact CAR-CODING.EDU.VN for a quote tailored to your specific needs.

10.4 What Types of Vehicles/Features are Supported?

VCDS primarily supports Volkswagen Audi Group (VAG) vehicles, including Volkswagen, Audi, Škoda, and SEAT. The specific features that can be coded vary depending on the vehicle model and year.

10.5 What Equipment is Required on the Technician’s End?

On the technician’s end, a computer with a stable internet connection, remote access software, and expertise in VCDS and vehicle coding are required.

10.6 How Can I Ensure the Safety of My Vehicle During Coding?

Ensure the safety of your vehicle during coding by using a genuine Ross-Tech VCDS cable, following proper procedures, and seeking professional assistance from experienced technicians.

10.7 What Can I Do If Something Goes Wrong During Coding?

If something goes wrong during coding, immediately stop the process and seek assistance from a professional. Do not attempt to fix the issue yourself, as this could potentially cause further damage. Contact CAR-CODING.EDU.VN for immediate assistance.

10.8 What Should I Do Before Starting Coding?

Before starting coding, make sure the car battery is fully charged and there are no other electrical issues.

10.9 Is it Possible to Damage My Car’s ECU While Coding?

Yes, it is possible to damage your car’s ECU while coding. However, the risk is low if you have professional assistance. Coding should be performed safely and reliably.

10.10 Is There a Way to Revert Coding Changes?

Yes, coding changes can typically be reverted to their original settings. However, it’s important to keep a record of the original coding values before making any changes, which can be saved.

Take Action Now

Don’t let complex coding tasks intimidate you. Whether you’re facing challenging coding tasks or need real-time assistance, CAR-CODING.EDU.VN is here to help. Our remote support provides expert assistance, ensuring accurate diagnostics and coding adjustments. Expand your garage’s capabilities and contact us today for a consultation. Visit CAR-CODING.EDU.VN or WhatsApp us at +1 (641) 206-8880 for immediate assistance. Our office is located at 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States.