Vcds Engine Measuring Blocks are crucial for diagnosing modern car issues. At CAR-CODING.EDU.VN, we offer expert remote support to navigate the complexities of engine diagnostics, ECU programming, and feature activation safely and efficiently. Our support enhances the skills of technicians, helping them tackle intricate coding issues and provide superior service.

Contents

- 1. What Are VCDS Engine Measuring Blocks?

- 1.1 How Do VCDS Measuring Blocks Work?

- 1.1.1 Communication Protocols

- 1.1.2 Data Interpretation

- 1.2 Why Are VCDS Measuring Blocks Important for Technicians?

- 2. Essential VCDS Measuring Blocks for Engine Diagnostics

- 2.1 Group 000: Engine Idle Speed and Basic Settings

- 2.2 Group 001: Injected Quantity

- 2.3 Group 003: EGR (Exhaust Gas Recirculation)

- 2.4 Group 004: Start of Injection Timing

- 2.5 Group 007: Temperatures

- 2.6 Group 013: Smooth Running Control

- 3. Advanced VCDS Techniques for Engine Tuning and Optimization

- 3.1 Adjusting Injection Timing

- 3.1.1 Procedure

- 3.2 EGR System Tuning

- 3.2.1 Procedure

- 3.3 Fuel Quantity Adjustment

- 3.3.1 Procedure

- 3.4 Air-Fuel Ratio Monitoring

- 3.4.1 Procedure

- 4. Common Issues Diagnosed Using VCDS Engine Measuring Blocks

- 4.1 MAF Sensor Problems

- 4.1.1 Symptoms

- 4.1.2 Diagnosis with VCDS

- 4.2 EGR Valve Problems

- 4.2.1 Symptoms

- 4.2.2 Diagnosis with VCDS

- 4.3 Fuel Injector Problems

- 4.3.1 Symptoms

- 4.3.2 Diagnosis with VCDS

- 4.4 Coolant Temperature Sensor Problems

- 4.4.1 Symptoms

- 4.4.2 Diagnosis with VCDS

- 4.5 Injection Timing Problems

- 4.5.1 Symptoms

- 4.5.2 Diagnosis with VCDS

- 5. Safety Precautions When Using VCDS

- 5.1 Proper Training

- 5.2 Reliable Equipment

- 5.3 Battery Voltage

- 5.4 Backups

- 5.5 Follow Instructions

- 5.6 Verify Changes

- 6. The Role of CAR-CODING.EDU.VN in VCDS Support

- 6.1 Remote Diagnostic Assistance

- 6.1.1 How It Works

- 6.2 ECU Programming and Coding Support

- 6.2.1 Services Offered

- 6.3 Real-Time Technical Support

- 6.3.1 Benefits

- 6.4 Training and Education

- 6.4.1 Training Modules

- 6.5 Custom Solutions

- 6.5.1 Examples

- 7. Activating Hidden Features with VCDS

- 7.1 Examples of Hidden Features

- 7.2 Safety Considerations

- 7.3 Step-by-Step Activation Process

- 7.4 Potential Risks and Mitigation

- 8. Remote Car Coding: The Future of Automotive Diagnostics

- 8.1 Benefits of Remote Coding

- 8.2 How Remote Coding Works

- 8.3 Security Measures

- 8.4 Choosing a Reliable Remote Coding Service

- 9. VCDS Engine Measuring Blocks: Examples and Interpretations

- 9.1 Example 1: Diagnosing a Faulty MAF Sensor

- 9.2 Example 2: Diagnosing an EGR Valve Issue

- 9.3 Example 3: Diagnosing Fuel Injector Problems

- 10. FAQ About VCDS Engine Measuring Blocks

- 10.1 Is It Safe to Perform Coding and Programming on My Car?

- 10.2 What Is the Process for Getting Remote Support from CAR-CODING.EDU.VN?

- 10.3 How Much Does Remote Coding Support Cost?

- 10.4 What Types of Vehicles and Features Do You Support?

- 10.5 What Equipment Do I Need to Connect for Remote Support?

- 10.6 How Can I Ensure the Security of My Vehicle During Remote Coding?

- 10.7 Can You Help Me Activate Hidden Features on My Car?

- 10.8 What Should I Do If Something Goes Wrong During Coding or Programming?

- 10.9 How Can I Learn More About VCDS and Coding Techniques?

- 10.10 What Are the Benefits of Using a Professional Service Like CAR-CODING.EDU.VN?

- Conclusion

1. What Are VCDS Engine Measuring Blocks?

VCDS (VAG-COM Diagnostic System) engine measuring blocks are sets of real-time data parameters from various sensors and systems within a vehicle’s engine, accessible through diagnostic software. These blocks provide critical insights into the engine’s performance, allowing technicians to monitor parameters like engine speed, temperature, fuel injection, and air mass. Understanding these readings is crucial for diagnosing issues and ensuring optimal engine operation.

Measuring blocks are essential for diagnosing engine problems because they offer a detailed view of the engine’s operational status. By observing how different parameters interact, technicians can pinpoint the source of a problem, whether it’s a faulty sensor, a malfunctioning valve, or an issue within the ECU. This real-time data stream helps in making informed decisions about repairs and adjustments.

1.1 How Do VCDS Measuring Blocks Work?

VCDS measuring blocks function by accessing data transmitted from various sensors and modules within the vehicle’s engine control unit (ECU). The VCDS software communicates with the ECU, requesting specific sets of data, which are then displayed in real-time on the technician’s computer. This data is organized into groups, each focusing on specific aspects of the engine’s performance.

1.1.1 Communication Protocols

The communication between VCDS and the ECU relies on standardized automotive communication protocols such as CAN (Controller Area Network), MOST (Media Oriented Systems Transport), FlexRay, and DoIP (Diagnostics over Internet Protocol). These protocols ensure reliable data transmission and allow VCDS to interact with a wide range of vehicle systems.

1.1.2 Data Interpretation

Interpreting the data from VCDS measuring blocks requires a solid understanding of engine mechanics and electronics. Technicians need to know the expected ranges for each parameter and how deviations from these ranges can indicate specific problems. For instance, an abnormal reading from the mass airflow (MAF) sensor could suggest a problem with the sensor itself, an air leak, or an issue with the EGR system.

1.2 Why Are VCDS Measuring Blocks Important for Technicians?

VCDS measuring blocks are vital for technicians for several reasons:

- Accurate Diagnostics: They provide real-time data, enabling precise identification of engine issues.

- Efficiency: They streamline the diagnostic process, saving time and reducing guesswork.

- Comprehensive Insights: They offer a holistic view of engine performance, helping to identify interconnected problems.

- Verification: They allow technicians to verify repairs by monitoring parameters after adjustments or replacements.

- Cost-Effectiveness: By pinpointing the exact problem, they help avoid unnecessary part replacements.

2. Essential VCDS Measuring Blocks for Engine Diagnostics

Navigating the multitude of measuring blocks can be daunting. Here are some essential groups that technicians frequently use for engine diagnostics, along with examples:

2.1 Group 000: Engine Idle Speed and Basic Settings

Group 000 provides a snapshot of the engine’s idle performance and is used to verify basic settings.

- Engine Idle Speed: Should be within the specified range (e.g., 870-950 RPM). Deviations can indicate idle control issues.

- Start of Injection: Indicates the timing of fuel injection. Incorrect timing can affect performance and emissions.

- Throttle Position: Should read 0% at idle. Any non-zero value indicates a throttle issue.

- Injection Quantity: Measures the amount of fuel injected per stroke. Abnormal values can suggest fuel delivery problems.

- Manifold Absolute Pressure: Measures the pressure in the intake manifold. Deviations can indicate vacuum leaks or boost issues.

- Engine Coolant Temperature: Displays the engine’s coolant temperature. Essential for diagnosing overheating or cooling system problems.

- Intake Manifold Temperature: Shows the temperature of the air entering the engine. High temperatures can reduce performance.

- Fuel Temperature: Indicates the temperature of the fuel. Extreme temperatures can affect fuel delivery and combustion.

- Air Mass: Measures the amount of air entering the engine. Critical for diagnosing air intake and EGR system issues.

2.2 Group 001: Injected Quantity

Group 001 focuses on the injected fuel quantity and related parameters.

- Engine RPM: Shows the engine’s current speed.

- Injected Quantity: Indicates the amount of fuel being injected (e.g., 2.2 – 9.0 mg/H).

- Modulating Piston Displacement Sensor Voltage: Measures the voltage from the sensor that monitors the position of the injection pump’s modulating piston.

- Engine Coolant Temperature Sensor: Displays the engine coolant temperature.

If the injected quantity is below 2.2 mg/H, the injection is running too rich; above 9.0 mg/H, it’s running too lean or the engine is cold. Similarly, voltage readings outside the 1.450 – 2.000 V range indicate rich or lean conditions.

2.3 Group 003: EGR (Exhaust Gas Recirculation)

Group 003 is crucial for diagnosing EGR system issues.

- Engine RPM: Shows the engine speed.

- Air Mass Drawn In (Specified): The expected amount of air entering the engine (e.g., 230 – 370 mg/H).

- Air Mass Drawn In (Actual): The actual amount of air entering the engine.

- EGR Vacuum Solenoid Duty Cycle: The percentage of time the EGR solenoid is active.

Deviations between specified and actual air mass can indicate EGR valve problems, air leaks, or a faulty MAF sensor. A constant air mass reading of approximately 550 mg/H often indicates a DTC (Diagnostic Trouble Code) is present.

2.4 Group 004: Start of Injection Timing

Group 004 monitors the start of injection timing.

- Engine RPM: Displays the engine speed.

- Start of Injection (Specified): The intended start of injection timing (e.g., 2 ATDC – 3 BTDC).

- Start of Injection (Actual): The actual start of injection timing.

- Cold Start Injector Duty Cycle: The percentage of time the cold start injector is active.

If the actual start of injection is significantly different from the specified value, it can indicate issues with the injection pump, timing settings, or the cold start injector.

2.5 Group 007: Temperatures

Group 007 provides temperature readings from various sensors.

- Fuel Temperature: Shows the temperature of the fuel.

- Air Intake Temperature: Displays the temperature of the air entering the engine.

- Engine Coolant Temperature: Indicates the engine’s coolant temperature.

These readings should be approximately equal to the ambient air temperature after the car has been sitting overnight. Significant deviations can indicate faulty sensors.

2.6 Group 013: Smooth Running Control

Group 013 shows the smooth running control injected quantity for each cylinder.

- Cylinder 1-4 Values: These values indicate how the ECU is balancing the power for each cylinder at idle (expected range: -2.0 to +2.0 mg/R).

Values outside this range suggest imbalances in cylinder performance due to variations in component tolerances, jet sizes, or compression issues.

3. Advanced VCDS Techniques for Engine Tuning and Optimization

Beyond basic diagnostics, VCDS can be used for advanced engine tuning and optimization.

3.1 Adjusting Injection Timing

VCDS allows technicians to fine-tune injection timing for optimal performance and fuel efficiency. By monitoring Group 004, technicians can adjust the injection pump settings to achieve the specified timing, ensuring efficient combustion.

3.1.1 Procedure

- Access Group 004 in VCDS.

- Observe the “Start of Injection (Actual)” value.

- Adjust the injection pump until the actual value matches the specified value.

- Verify the changes by rechecking the measuring block.

3.2 EGR System Tuning

VCDS can be used to adjust the EGR system for improved emissions and engine performance. By monitoring Group 003, technicians can modify the EGR vacuum solenoid duty cycle to optimize the amount of exhaust gas recirculated into the engine.

3.2.1 Procedure

- Access Group 003 in VCDS.

- Observe the “Air Mass Drawn In (Actual)” value.

- Adjust the EGR vacuum solenoid duty cycle to achieve the desired air mass value.

- Verify the changes by rechecking the measuring block.

3.3 Fuel Quantity Adjustment

VCDS enables technicians to adjust the fuel quantity for optimal fuel consumption and power output. By monitoring Group 001, adjustments can be made to the injection quantity to ensure the engine is running neither too rich nor too lean.

3.3.1 Procedure

- Access Group 001 in VCDS.

- Observe the “Injected Quantity” value.

- Adjust the fuel quantity settings to achieve the desired value.

- Verify the changes by rechecking the measuring block.

3.4 Air-Fuel Ratio Monitoring

Monitoring the air-fuel ratio is crucial for engine performance and emissions. VCDS allows technicians to monitor the air mass and injected quantity to ensure the engine is running at the optimal air-fuel ratio.

3.4.1 Procedure

- Access Groups 000 and 001 in VCDS.

- Observe the “Air Mass” and “Injected Quantity” values.

- Calculate the air-fuel ratio based on these values.

- Adjust the fuel quantity or air intake settings to achieve the desired air-fuel ratio.

- Verify the changes by rechecking the measuring blocks.

4. Common Issues Diagnosed Using VCDS Engine Measuring Blocks

VCDS engine measuring blocks are invaluable for diagnosing a wide array of engine issues. Here are some common problems that can be identified using these tools:

4.1 MAF Sensor Problems

MAF sensor issues can lead to poor engine performance, reduced fuel economy, and increased emissions.

4.1.1 Symptoms

- Rough idling

- Poor acceleration

- Stalling

- Check engine light

4.1.2 Diagnosis with VCDS

Using Group 003, compare the “Air Mass Drawn In (Specified)” and “Air Mass Drawn In (Actual)” values. Significant discrepancies indicate a faulty MAF sensor or air leaks.

4.2 EGR Valve Problems

EGR valve issues can cause drivability problems and increased emissions.

4.2.1 Symptoms

- Rough idling

- Poor acceleration

- Increased emissions

- Check engine light

4.2.2 Diagnosis with VCDS

Using Group 003, monitor the “EGR Vacuum Solenoid Duty Cycle” and “Air Mass Drawn In (Actual)” values. Abnormal readings suggest EGR valve malfunction.

4.3 Fuel Injector Problems

Faulty fuel injectors can lead to misfires, poor fuel economy, and engine damage.

4.3.1 Symptoms

- Misfires

- Poor fuel economy

- Rough idling

- Check engine light

4.3.2 Diagnosis with VCDS

Using Group 013, monitor the smooth running control values for each cylinder. Values outside the -2.0 to +2.0 mg/R range indicate fuel injector issues.

4.4 Coolant Temperature Sensor Problems

Coolant temperature sensor issues can affect engine performance and fuel economy.

4.4.1 Symptoms

- Poor fuel economy

- Hard starting

- Overheating

- Check engine light

4.4.2 Diagnosis with VCDS

Using Group 007, monitor the “Engine Coolant Temperature” value. Significant deviations from ambient temperature indicate a faulty sensor.

4.5 Injection Timing Problems

Incorrect injection timing can lead to poor performance and increased emissions.

4.5.1 Symptoms

- Poor performance

- Increased emissions

- Hard starting

- Engine knocking

4.5.2 Diagnosis with VCDS

Using Group 004, compare the “Start of Injection (Specified)” and “Start of Injection (Actual)” values. Discrepancies suggest injection timing problems.

5. Safety Precautions When Using VCDS

Using VCDS involves accessing and modifying sensitive vehicle systems, so it’s crucial to follow safety precautions.

5.1 Proper Training

Ensure you have adequate training and understanding of VCDS software and vehicle systems before performing any diagnostic or coding procedures.

5.2 Reliable Equipment

Use a genuine VCDS interface and a stable computer with a reliable power source to avoid data corruption or communication errors.

5.3 Battery Voltage

Maintain a stable battery voltage during coding and programming procedures. Use a battery charger or maintainer to prevent voltage drops that can interrupt the process and damage the ECU.

5.4 Backups

Before making any changes, back up the original ECU data. This allows you to revert to the original settings if something goes wrong.

5.5 Follow Instructions

Adhere to the instructions provided by VCDS and the vehicle manufacturer. Incorrect coding or programming can lead to serious problems and potential damage to the vehicle.

5.6 Verify Changes

After making any changes, verify the results using VCDS measuring blocks. Ensure the parameters are within the specified ranges and that the vehicle is functioning correctly.

6. The Role of CAR-CODING.EDU.VN in VCDS Support

CAR-CODING.EDU.VN plays a crucial role in providing expert support for technicians using VCDS. Our services enhance the diagnostic and coding capabilities of automotive professionals, ensuring efficient and safe vehicle maintenance.

6.1 Remote Diagnostic Assistance

We offer remote diagnostic assistance to help technicians interpret VCDS data and troubleshoot complex engine problems. Our experts can remotely access your VCDS data, analyze the measuring blocks, and provide step-by-step guidance to identify and resolve issues.

6.1.1 How It Works

- Connect your VCDS interface to the vehicle and your computer.

- Contact CAR-CODING.EDU.VN for remote assistance.

- Grant our experts remote access to your computer.

- Our experts analyze the VCDS data and provide diagnostic guidance.

6.2 ECU Programming and Coding Support

Our team provides comprehensive ECU programming and coding support, ensuring that changes are made safely and correctly. We offer guidance on coding procedures, feature activation, and ECU updates.

6.2.1 Services Offered

- ECU flashing and updates

- Feature activation (e.g., enabling hidden features)

- VIN coding

- Variant coding

6.3 Real-Time Technical Support

We offer real-time technical support to assist technicians during coding and programming procedures. Our experts are available to answer questions, provide guidance, and troubleshoot issues as they arise.

6.3.1 Benefits

- Immediate assistance during critical procedures

- Expert guidance to avoid mistakes

- Reduced risk of ECU damage

6.4 Training and Education

CAR-CODING.EDU.VN provides training and educational resources to help technicians improve their VCDS skills. Our training programs cover a wide range of topics, from basic diagnostics to advanced coding techniques.

6.4.1 Training Modules

- VCDS Basics: Understanding Measuring Blocks

- Advanced Coding Techniques

- ECU Programming and Flashing

- Troubleshooting Common Issues

6.5 Custom Solutions

We offer custom solutions tailored to the specific needs of your shop or repair facility. Whether you need assistance with a particular vehicle model or help setting up a VCDS diagnostic station, our team can provide the support you need.

6.5.1 Examples

- Customized coding procedures

- Remote setup of VCDS diagnostic stations

- On-site training for your team

7. Activating Hidden Features with VCDS

One of the exciting capabilities of VCDS is the ability to activate hidden features in vehicles. These features, often disabled by default, can enhance the vehicle’s functionality and personalization.

7.1 Examples of Hidden Features

- Coming Home/Leaving Home Lights: Automatically activate headlights when unlocking or locking the vehicle.

- Cornering Lights: Activate fog lights when turning to improve visibility.

- Gauge Staging: Sweep the instrument cluster needles upon startup for a sporty look.

- Emergency Brake Flashing: Automatically activate hazard lights during hard braking.

- Seatbelt Warning Chime Disable: Disable the annoying seatbelt warning chime.

7.2 Safety Considerations

While activating hidden features can be fun, it’s important to consider safety implications. Ensure that any activated feature complies with local regulations and does not compromise vehicle safety.

7.3 Step-by-Step Activation Process

- Connect VCDS to the vehicle.

- Access the appropriate control module (e.g., Central Electronics, Body Control Module).

- Navigate to the coding section.

- Modify the coding values to activate the desired feature.

- Test the activated feature to ensure it functions correctly.

- If needed, seek expert help from CAR-CODING.EDU.VN

7.4 Potential Risks and Mitigation

Incorrect coding can lead to unexpected behavior or system malfunctions. Always back up the original coding values and proceed with caution. If unsure, seek assistance from CAR-CODING.EDU.VN.

8. Remote Car Coding: The Future of Automotive Diagnostics

Remote car coding is revolutionizing the automotive diagnostics industry, offering technicians and repair shops unprecedented flexibility and expertise.

8.1 Benefits of Remote Coding

- Access to Experts: Connect with specialized coders and programmers who have expertise in various vehicle makes and models.

- Cost Savings: Reduce the need for expensive in-house specialists and equipment.

- Time Efficiency: Resolve coding issues quickly and efficiently, minimizing downtime.

- Wide Range of Services: Access a broad spectrum of coding services, from basic diagnostics to advanced ECU programming.

8.2 How Remote Coding Works

- Connect your diagnostic tool (e.g., VCDS) to the vehicle.

- Contact a remote coding service like CAR-CODING.EDU.VN.

- Grant the remote coder access to your computer via a secure connection.

- The coder performs the necessary coding or programming tasks remotely.

- Verify the changes and functionality of the vehicle.

8.3 Security Measures

Remote coding involves accessing sensitive vehicle systems, so security is paramount. Ensure that the remote coding service uses secure connections and data encryption to protect against unauthorized access.

8.4 Choosing a Reliable Remote Coding Service

- Expertise: Verify the credentials and experience of the remote coders.

- Security: Ensure the service uses secure connections and data encryption.

- Support: Choose a service that offers reliable technical support.

- Reputation: Check reviews and testimonials from other users.

9. VCDS Engine Measuring Blocks: Examples and Interpretations

To further illustrate the use of VCDS engine measuring blocks, let’s look at some specific examples and their interpretations.

9.1 Example 1: Diagnosing a Faulty MAF Sensor

Vehicle: 2015 Volkswagen Golf TDI

Problem: Poor performance and reduced fuel economy.

VCDS Procedure:

- Connect VCDS to the vehicle.

- Access Engine Control Module (01).

- Select Measuring Blocks (08).

- Enter Group 003.

- Observe the “Air Mass Drawn In (Specified)” and “Air Mass Drawn In (Actual)” values at idle and during acceleration.

Readings:

- Idle: Specified = 300 mg/H, Actual = 500 mg/H

- Acceleration: Specified = 800 mg/H, Actual = 1200 mg/H

Interpretation:

The actual air mass values are significantly higher than the specified values, indicating a faulty MAF sensor. The sensor is overreporting the amount of air entering the engine, causing the ECU to inject too much fuel, resulting in poor performance and reduced fuel economy.

Solution:

Replace the MAF sensor and clear any related DTCs.

9.2 Example 2: Diagnosing an EGR Valve Issue

Vehicle: 2016 Audi A3 TDI

Problem: Rough idling and increased emissions.

VCDS Procedure:

- Connect VCDS to the vehicle.

- Access Engine Control Module (01).

- Select Measuring Blocks (08).

- Enter Group 003.

- Observe the “EGR Vacuum Solenoid Duty Cycle” and “Air Mass Drawn In (Actual)” values at idle.

Readings:

- EGR Vacuum Solenoid Duty Cycle: 0%

- Air Mass Drawn In (Actual): 550 mg/H

Interpretation:

The EGR vacuum solenoid duty cycle is 0%, indicating that the EGR valve is not opening. The air mass drawn in is higher than expected, suggesting that the EGR valve is stuck closed, leading to rough idling and increased emissions.

Solution:

Inspect and clean or replace the EGR valve.

9.3 Example 3: Diagnosing Fuel Injector Problems

Vehicle: 2014 BMW 328i

Problem: Misfires and rough running.

VCDS Procedure:

- Connect VCDS to the vehicle.

- Access Engine Control Module (01).

- Select Measuring Blocks (08).

- Enter Group 013.

- Observe the smooth running control values for each cylinder at idle.

Readings:

- Cylinder 1: -0.5 mg/R

- Cylinder 2: +2.5 mg/R

- Cylinder 3: -1.0 mg/R

- Cylinder 4: -1.0 mg/R

Interpretation:

The smooth running control value for cylinder 2 is significantly outside the acceptable range (-2.0 to +2.0 mg/R), indicating a fuel injector problem in that cylinder.

Solution:

Inspect and clean or replace the fuel injector in cylinder 2.

10. FAQ About VCDS Engine Measuring Blocks

Here are some frequently asked questions about using VCDS engine measuring blocks for diagnostics:

10.1 Is It Safe to Perform Coding and Programming on My Car?

Yes, coding and programming are generally safe if performed by trained professionals using reliable equipment. However, incorrect coding can lead to system malfunctions, so it’s crucial to follow safety precautions and seek expert assistance when needed.

10.2 What Is the Process for Getting Remote Support from CAR-CODING.EDU.VN?

To get remote support, contact CAR-CODING.EDU.VN via WhatsApp at +1 (641) 206-8880 or visit our website at CAR-CODING.EDU.VN. Our experts will guide you through the process of connecting your diagnostic tool and granting remote access to your computer.

10.3 How Much Does Remote Coding Support Cost?

The cost of remote coding support varies depending on the complexity of the task and the vehicle model. Contact CAR-CODING.EDU.VN for a customized quote.

10.4 What Types of Vehicles and Features Do You Support?

We support a wide range of vehicle makes and models, including Volkswagen, Audi, BMW, Mercedes-Benz, and more. Our services include ECU programming, feature activation, VIN coding, and variant coding.

10.5 What Equipment Do I Need to Connect for Remote Support?

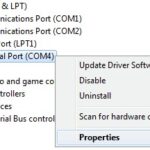

To connect for remote support, you will need a VCDS interface, a stable computer with a reliable internet connection, and a secure remote access tool. Our experts will provide guidance on setting up the connection.

10.6 How Can I Ensure the Security of My Vehicle During Remote Coding?

Ensure that the remote coding service uses secure connections and data encryption to protect against unauthorized access. CAR-CODING.EDU.VN employs industry-standard security measures to safeguard your vehicle’s data.

10.7 Can You Help Me Activate Hidden Features on My Car?

Yes, we can help you activate hidden features on your car. Our experts can guide you through the coding process and ensure that the activated features function correctly.

10.8 What Should I Do If Something Goes Wrong During Coding or Programming?

If something goes wrong during coding or programming, immediately disconnect the diagnostic tool and contact CAR-CODING.EDU.VN for assistance. Our experts can help you troubleshoot the issue and restore the original settings if necessary.

10.9 How Can I Learn More About VCDS and Coding Techniques?

CAR-CODING.EDU.VN offers training and educational resources to help technicians improve their VCDS skills. Visit our website for more information on our training programs.

10.10 What Are the Benefits of Using a Professional Service Like CAR-CODING.EDU.VN?

Using a professional service like CAR-CODING.EDU.VN ensures that coding and programming tasks are performed safely and correctly by experienced experts. This reduces the risk of system malfunctions and potential damage to the vehicle.

Alt text: A technician using VCDS software to diagnose engine performance, displaying real-time data parameters on a laptop screen.

Conclusion

VCDS engine measuring blocks are powerful tools for diagnosing and optimizing modern vehicle engines. By understanding how to interpret these blocks and following safety precautions, technicians can efficiently identify and resolve a wide range of engine issues. CAR-CODING.EDU.VN offers expert support to enhance your VCDS capabilities, providing remote diagnostic assistance, ECU programming support, and real-time technical guidance. Contact us today at +1 (641) 206-8880 or visit CAR-CODING.EDU.VN to learn more. Our office is located at 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States.