Are you struggling to diagnose fuel pressure issues in your VW or Audi using VCDS? CAR-CODING.EDU.VN offers expert remote car coding assistance to help you accurately measure fuel rail pressure and troubleshoot engine problems. Our team of experienced technicians provides safe and efficient coding, ECU programming, and hidden feature activation services.

Contents

- 1. Understanding VAG 106 VCDS and Fuel Rail Pressure Measurement

- 1.1 What is VCDS?

- 1.2 Why Measure Fuel Rail Pressure?

- 1.3 The Challenge: Finding the Correct Measuring Blocks in VCDS

- 2. Troubleshooting VAG 106 VCDS Fuel Rail Pressure Measurement Issues

- 2.1 Verify VCDS Compatibility and Updates

- 2.2 Check the Ross-Tech Wiki and VCDS Forums

- 2.3 Use Advanced Measuring Blocks (If Available)

- 2.4 Search for Relevant Keywords in Advanced Measuring Blocks

- 2.5 Consider the Units of Measurement

- 2.6 Check Wiring and Sensor Connections

- 2.7 Consult a Factory Repair Manual

- 3. Understanding Measuring Blocks vs. Advanced Measuring Values

- 3.1 Measuring Blocks (Standard Mode)

- 3.2 Advanced Measuring Values (Advanced Mode)

- 3.3 When to Use Each Method

- 4. Specific VCDS Procedures for Measuring Fuel Rail Pressure

- 4.1 Connect VCDS to the Vehicle

- 4.2 Select the Engine Control Module (ECU)

- 4.3 Access Measuring Blocks or Advanced Measuring Values

- 4.4 Locate Fuel Rail Pressure Data

- 4.5 Monitor Fuel Rail Pressure Readings

- 4.6 Example: Using Advanced Measuring Values

- 5. Common Fuel System Issues Affecting Fuel Rail Pressure

- 5.1 Fuel Pump Problems

- 5.2 Fuel Pressure Regulator Issues

- 5.3 Fuel Injector Problems

- 5.4 Fuel Line Leaks

- 5.5 Sensor Malfunctions

- 6. The Importance of Accurate Diagnosis

- 6.1 Understanding Fuel Trim Values

- 6.2 Interpreting Fuel Trim Values

- 6.3 Using Fuel Trim for Diagnosis

- 6.4 Example: Diagnosing a Vacuum Leak

- 7. Remote Car Coding Assistance with CAR-CODING.EDU.VN

- 7.1 Benefits of Remote Car Coding Assistance

- 7.2 How Remote Car Coding Assistance Works

- 8. Understanding Vehicle Diagnostics Using VCDS

- 8.1 Control Modules and ECUs

- 8.2 Diagnostic Trouble Codes (DTCs)

- 8.3 Live Data and Measuring Blocks

- 8.4 Output Tests

- 8.5 Adaptations and Coding

- 8.6 Communication Protocols

- 9. Common VCDS Coding and Adaptation Procedures

- 9.1 Enabling Hidden Features

- 9.2 Retrofitting Equipment

- 9.3 Adjusting Lighting Settings

- 9.4 Adjusting Suspension Settings

- 9.5 Key Coding

- 9.6 ECU Flashing

- 10. Safety Precautions When Using VCDS

- 10.1 Use a Stable Power Supply

- 10.2 Follow Instructions Carefully

- 10.3 Back Up Control Module Data

- 10.4 Disconnect Unnecessary Accessories

- 10.5 Use a Genuine VCDS Interface

- 11. VAG 106 VCDS FAQ

- 11.1 Is it safe to perform car coding myself?

- 11.2 What is involved in the remote support process?

- 11.3 How much does remote coding support cost?

- 11.4 What types of vehicles and features do you support?

- 11.5 What equipment do I need for remote support?

- 11.6 Can remote coding void my car’s warranty?

- 11.7 How long does a typical remote coding session take?

- 11.8 What if something goes wrong during the coding process?

- 11.9 Can you help me find hidden features in my car?

- 11.10 Do you offer support for other diagnostic tools besides VCDS?

1. Understanding VAG 106 VCDS and Fuel Rail Pressure Measurement

Vag 106 Vcds is a powerful diagnostic tool used for Volkswagen Automotive Group (VAG) vehicles, including VW, Audi, Skoda, and SEAT. While VCDS offers extensive diagnostic capabilities, measuring fuel rail pressure can sometimes be challenging due to variations in vehicle models and software versions.

1.1 What is VCDS?

VCDS (VAG-COM Diagnostic System) is a software application used with a diagnostic interface to communicate with the electronic control units (ECUs) in VAG vehicles. It allows technicians to:

- Read and clear diagnostic trouble codes (DTCs)

- View live data from sensors and actuators

- Perform output tests

- Adapt and code control modules

- Flash ECU software

1.2 Why Measure Fuel Rail Pressure?

Measuring fuel rail pressure is crucial for diagnosing various engine-related issues, such as:

- Hard starting or no-start conditions

- Engine misfires

- Poor fuel economy

- Loss of power

- Fuel system leaks

Low fuel rail pressure can prevent the engine from starting or running properly, while excessively high pressure can damage fuel system components.

1.3 The Challenge: Finding the Correct Measuring Blocks in VCDS

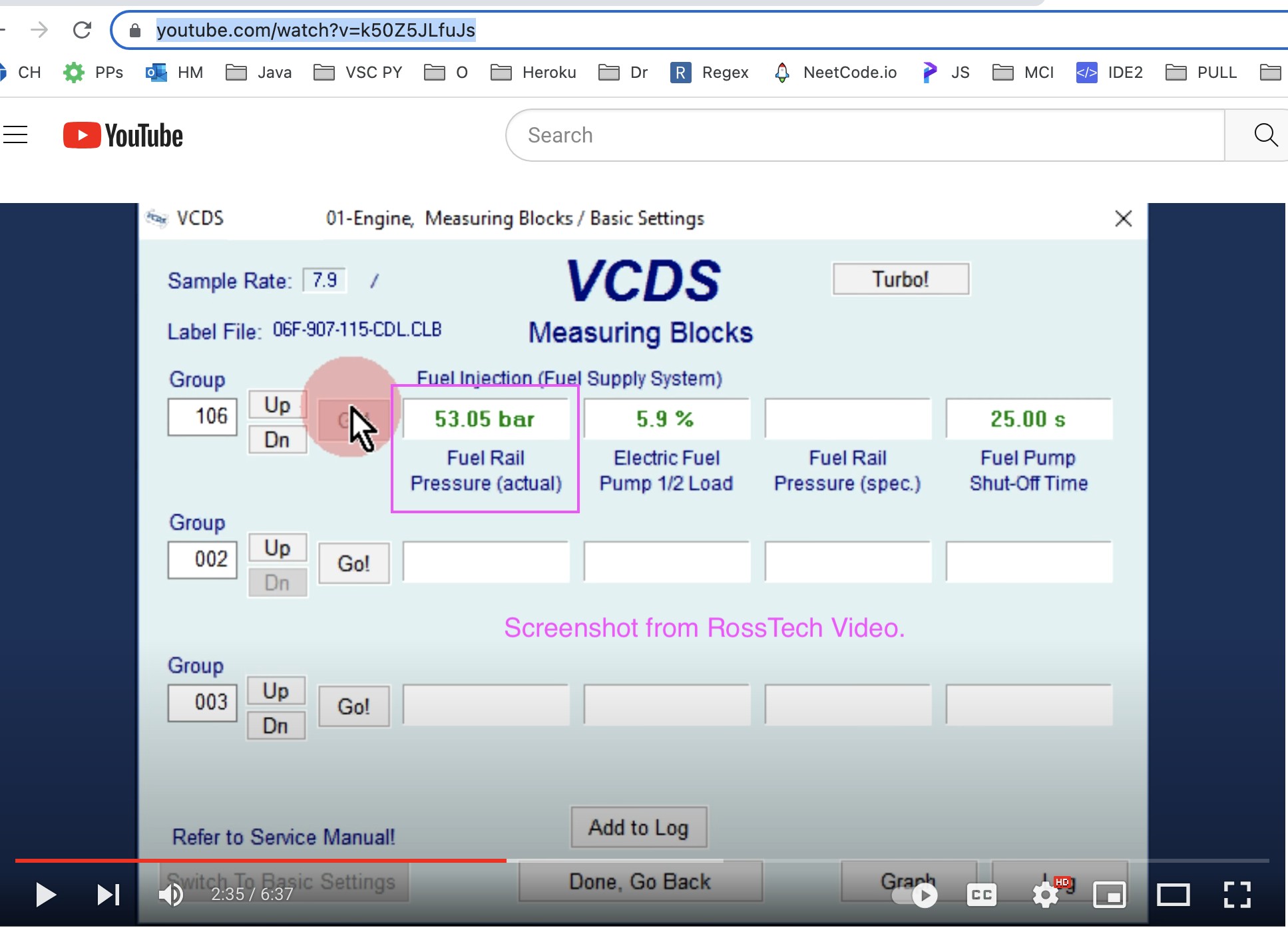

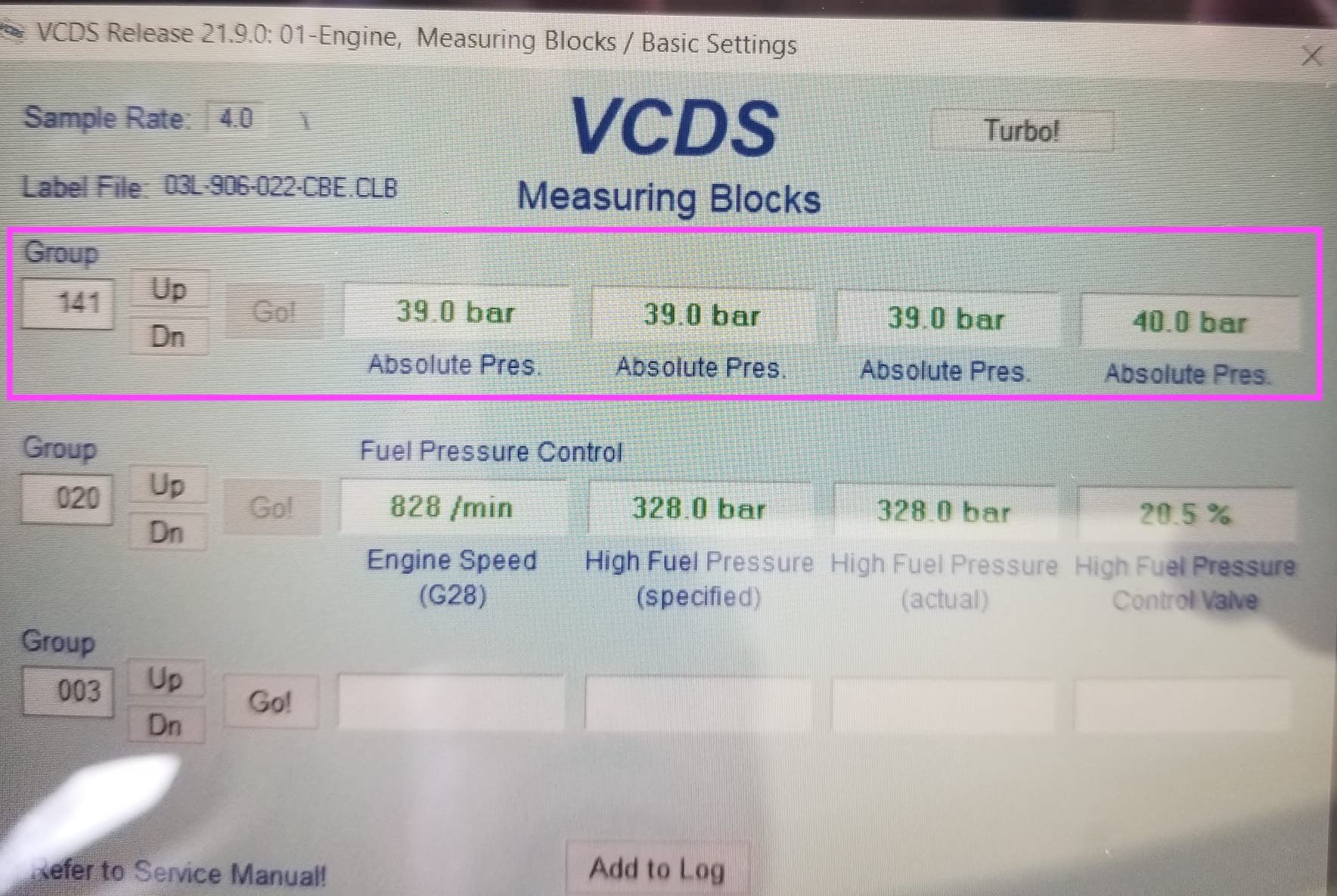

The original poster’s issue highlights a common challenge: locating the correct measuring blocks in VCDS to read fuel rail pressure. The specific measuring blocks can vary depending on the vehicle’s engine type, model year, and ECU software version.

In the original post, the user was unable to find fuel rail pressure data in the measuring blocks suggested by a Ross-Tech video (groups 106, 140, 141, and 230). This indicates that those specific measuring blocks may not be applicable to their 2012 VW Jetta SportWagen TDI (engine code CJAA).

2. Troubleshooting VAG 106 VCDS Fuel Rail Pressure Measurement Issues

If you’re having trouble finding fuel rail pressure data in VCDS, follow these troubleshooting steps:

2.1 Verify VCDS Compatibility and Updates

Ensure that you are using a genuine VCDS interface and that your software is up to date. Older or non-genuine interfaces may not have complete access to all measuring blocks or may provide inaccurate data. Ross-Tech regularly releases software updates that include new measuring blocks and improved compatibility with newer vehicles.

2.2 Check the Ross-Tech Wiki and VCDS Forums

The Ross-Tech Wiki is a valuable resource for VCDS users, providing information on various diagnostic procedures and measuring block locations. Search the Wiki for your specific vehicle model and engine type to see if there are any specific instructions for measuring fuel rail pressure.

The Ross-Tech forums are also a great place to ask questions and get help from experienced VCDS users.

2.3 Use Advanced Measuring Blocks (If Available)

Some ECUs may not display fuel rail pressure in the standard measuring blocks. In these cases, you may need to use the “Advanced Measuring Blocks” or “Advanced ID” function in VCDS. This allows you to select specific parameters to monitor, including fuel rail pressure.

2.4 Search for Relevant Keywords in Advanced Measuring Blocks

When using Advanced Measuring Blocks, try searching for relevant keywords such as “fuel,” “rail,” or “pressure” to filter the available parameters. This can help you quickly locate the fuel rail pressure sensor reading.

2.5 Consider the Units of Measurement

Fuel rail pressure can be displayed in different units, such as bar, kPa, or PSI. Make sure you understand the units being used and compare the readings to the expected values for your vehicle. Consult your vehicle’s repair manual or a trusted online resource for the correct fuel rail pressure specifications.

2.6 Check Wiring and Sensor Connections

If you are still unable to obtain a fuel rail pressure reading, there may be a problem with the fuel rail pressure sensor or its wiring. Inspect the sensor and its connector for any signs of damage or corrosion. Use a multimeter to check the sensor’s wiring for continuity and proper voltage.

2.7 Consult a Factory Repair Manual

Factory repair manuals often contain detailed information on diagnostic procedures and measuring block locations for specific vehicle models. If you are having trouble finding the information you need in VCDS or online resources, consult a factory repair manual for your vehicle.

3. Understanding Measuring Blocks vs. Advanced Measuring Values

VCDS provides two primary methods for accessing live data: Measuring Blocks and Advanced Measuring Values. Understanding the difference between these methods can help you locate the information you need more efficiently.

3.1 Measuring Blocks (Standard Mode)

- Predefined Groups: Measuring Blocks consist of predefined groups of data, typically containing 3-4 related parameters.

- Limited Customization: You cannot customize the parameters displayed in a Measuring Block.

- Ease of Use: Measuring Blocks are generally easier to use for basic diagnostics, as the parameters are already grouped together.

3.2 Advanced Measuring Values (Advanced Mode)

- Individual Selection: Advanced Measuring Values allow you to select individual parameters to monitor from a comprehensive list.

- Highly Customizable: You can create custom displays with only the parameters you need.

- Greater Flexibility: Advanced Measuring Values are ideal for in-depth diagnostics and troubleshooting specific issues.

- Complexity: Requires more knowledge to configure properly, as you need to know the specific names or IDs of the parameters you want to monitor.

3.3 When to Use Each Method

- Measuring Blocks: Use Measuring Blocks for general diagnostics and monitoring common parameters. If you find a Measuring Block that contains the data you need, it’s often the quickest and easiest option.

- Advanced Measuring Values: Use Advanced Measuring Values when you need to monitor specific parameters that are not available in the standard Measuring Blocks or when you want to create a custom display for in-depth troubleshooting.

4. Specific VCDS Procedures for Measuring Fuel Rail Pressure

While the exact steps may vary slightly depending on the vehicle model, here’s a general procedure for measuring fuel rail pressure using VCDS:

4.1 Connect VCDS to the Vehicle

- Connect your VCDS interface to the vehicle’s OBD-II port.

- Turn on the ignition, but do not start the engine.

- Launch the VCDS software on your computer.

4.2 Select the Engine Control Module (ECU)

- In VCDS, select “Select Control Module.”

- Choose the “01-Engine” control module.

4.3 Access Measuring Blocks or Advanced Measuring Values

- Click on “Measuring Blocks” or “Advanced Measuring Values,” depending on the method you prefer.

4.4 Locate Fuel Rail Pressure Data

- Measuring Blocks: Browse through the available Measuring Blocks to see if any of them contain fuel rail pressure data. Look for blocks with names like “Fuel Pressure,” “Rail Pressure,” or similar terms.

- Advanced Measuring Values: In Advanced Measuring Values, search for “Fuel Rail Pressure” or similar terms in the list of available parameters.

4.5 Monitor Fuel Rail Pressure Readings

- Once you have located the fuel rail pressure data, monitor the readings while the engine is off (ignition on) and while the engine is running.

- Compare the readings to the expected values for your vehicle.

4.6 Example: Using Advanced Measuring Values

- In VCDS, select “Select Control Module.”

- Choose the “01-Engine” control module.

- Click on “Advanced Measuring Values.”

- In the “Group Filter,” type “Fuel Rail Pressure” or “Rail Pressure.”

- Select the parameter that corresponds to fuel rail pressure.

- Click “Add to List.”

- Click “OK” to view the live data.

5. Common Fuel System Issues Affecting Fuel Rail Pressure

Several fuel system issues can cause low or high fuel rail pressure. Here are some of the most common:

5.1 Fuel Pump Problems

- Weak Fuel Pump: A failing fuel pump may not be able to deliver enough fuel to the fuel rail, resulting in low pressure.

- Clogged Fuel Filter: A clogged fuel filter restricts fuel flow to the pump, reducing its output.

- Fuel Pump Relay Failure: A faulty fuel pump relay can prevent the pump from running or cause it to run intermittently.

5.2 Fuel Pressure Regulator Issues

- Faulty Regulator: A malfunctioning fuel pressure regulator can cause the pressure to be too low or too high.

- Vacuum Leaks: Vacuum leaks in the regulator’s vacuum line can affect its ability to maintain the correct pressure.

5.3 Fuel Injector Problems

- Leaking Injectors: Leaking fuel injectors can cause a drop in fuel rail pressure when the engine is off.

- Clogged Injectors: Clogged injectors restrict fuel flow, which can affect engine performance.

5.4 Fuel Line Leaks

- Damaged Fuel Lines: Leaks in the fuel lines can cause a loss of fuel pressure.

- Loose Connections: Loose fuel line connections can also lead to leaks.

5.5 Sensor Malfunctions

- Faulty Fuel Rail Pressure Sensor: If the fuel rail pressure sensor is faulty, it may provide inaccurate readings, leading to incorrect diagnosis.

6. The Importance of Accurate Diagnosis

Accurate diagnosis is essential for resolving fuel system issues effectively. Relying solely on VCDS readings without understanding the underlying principles of fuel system operation can lead to misdiagnosis and unnecessary repairs.

6.1 Understanding Fuel Trim Values

Fuel trim values provide valuable insights into how the engine control unit (ECU) is compensating for deviations in the air-fuel mixture. Analyzing fuel trim data can help you identify potential fuel system problems.

- Short-Term Fuel Trim (STFT): STFT reflects immediate adjustments the ECU is making to maintain the ideal air-fuel ratio.

- Long-Term Fuel Trim (LTFT): LTFT represents the accumulated adjustments the ECU has made over time.

6.2 Interpreting Fuel Trim Values

-

Positive Fuel Trim (e.g., +10%): Indicates that the ECU is adding fuel to compensate for a lean condition (too much air, not enough fuel). This could be due to:

- Vacuum leaks

- Low fuel pressure

- Faulty mass airflow (MAF) sensor

- Clogged fuel injectors

-

Negative Fuel Trim (e.g., -10%): Indicates that the ECU is reducing fuel to compensate for a rich condition (too much fuel, not enough air). This could be due to:

- Leaking fuel injectors

- High fuel pressure

- Faulty oxygen (O2) sensor

- Restricted air filter

6.3 Using Fuel Trim for Diagnosis

- Monitor STFT and LTFT: Use VCDS to monitor both STFT and LTFT values while the engine is running at idle and under load.

- Analyze the Trends:

- High positive LTFT values suggest a persistent lean condition.

- High negative LTFT values suggest a persistent rich condition.

- Large fluctuations in STFT values may indicate a transient issue.

- Identify Potential Causes: Based on the fuel trim trends, investigate potential causes such as vacuum leaks, fuel pressure problems, or sensor malfunctions.

- Perform Further Testing: Use other diagnostic tools and procedures to confirm your diagnosis and pinpoint the exact cause of the problem.

6.4 Example: Diagnosing a Vacuum Leak

If you observe high positive LTFT values at idle, suspect a vacuum leak. A vacuum leak allows unmetered air to enter the engine, causing a lean condition. To confirm, use a smoke tester to introduce smoke into the intake system and look for leaks.

7. Remote Car Coding Assistance with CAR-CODING.EDU.VN

If you’re struggling with VCDS diagnostics or need assistance with car coding, CAR-CODING.EDU.VN offers expert remote support. Our experienced technicians can help you:

- Accurately measure fuel rail pressure using VCDS

- Diagnose fuel system problems

- Perform ECU programming and coding

- Activate hidden features

- Clear fault codes permanently

- Provide real-time technical support

7.1 Benefits of Remote Car Coding Assistance

- Expert Guidance: Our technicians have extensive experience with VAG vehicles and VCDS.

- Safe and Reliable Coding: We ensure that all coding procedures are performed safely and reliably.

- Time and Cost Savings: Remote assistance can save you time and money compared to taking your vehicle to a dealership or specialist.

- Convenient Support: Get the help you need from the comfort of your own garage.

- Wide Range of Services: We offer a comprehensive range of car coding and programming services.

7.2 How Remote Car Coding Assistance Works

- Contact Us: Reach out to CAR-CODING.EDU.VN via Whatsapp +1 (641) 206-8880 or visit our website CAR-CODING.EDU.VN.

- Describe Your Issue: Explain the problem you’re experiencing and the type of assistance you need.

- Connect Remotely: Our technician will guide you through the process of connecting your VCDS interface to your vehicle and establishing a remote connection.

- Receive Expert Support: Our technician will remotely access your VCDS software and provide expert guidance and assistance.

8. Understanding Vehicle Diagnostics Using VCDS

Vehicle diagnostics using VCDS (VAG-COM Diagnostic System) is a complex process that requires a deep understanding of automotive systems and software. Here’s a detailed breakdown of key aspects:

8.1 Control Modules and ECUs

Modern vehicles contain numerous electronic control units (ECUs), also known as control modules. These modules manage various functions, such as:

- Engine Control Module (ECM): Manages engine operation, fuel injection, ignition, and emissions.

- Transmission Control Module (TCM): Controls automatic transmission functions.

- Anti-lock Braking System (ABS) Module: Manages ABS and stability control systems.

- Airbag Control Module: Controls airbag deployment.

- Body Control Module (BCM): Manages various body functions, such as lighting, door locks, and wipers.

- Instrument Cluster: Displays vehicle information, such as speed, RPM, and fuel level.

VCDS allows you to communicate with each of these modules to diagnose problems, read data, and perform coding and adaptations.

8.2 Diagnostic Trouble Codes (DTCs)

When a fault occurs in a vehicle system, the corresponding control module stores a diagnostic trouble code (DTC). These codes provide valuable information about the nature and location of the fault.

- Reading DTCs: VCDS allows you to read DTCs from each control module. The codes are typically displayed with a code number (e.g., P0171) and a description of the fault.

- Interpreting DTCs: DTCs are standardized across the industry, but it’s essential to consult the vehicle’s repair manual or a reliable online resource to understand the specific meaning of each code.

- Clearing DTCs: After repairing a fault, you can use VCDS to clear the DTC from the control module. However, it’s crucial to ensure that the fault is actually resolved before clearing the code, as it may reappear if the problem persists.

8.3 Live Data and Measuring Blocks

VCDS allows you to view live data from sensors and actuators in real-time. This data can be invaluable for diagnosing intermittent faults or monitoring system performance.

- Measuring Blocks: Measuring blocks are predefined groups of related data parameters. Each block typically contains 3-4 parameters.

- Advanced Measuring Values: Advanced measuring values allow you to select individual parameters to monitor from a comprehensive list. This provides greater flexibility for in-depth diagnostics.

- Graphing Data: VCDS allows you to graph live data, which can be helpful for visualizing trends and identifying anomalies.

8.4 Output Tests

Output tests allow you to activate specific components in the vehicle to verify their operation. For example, you can use an output test to activate the fuel pump, turn on the headlights, or cycle the ABS solenoids.

8.5 Adaptations and Coding

Adaptations and coding allow you to modify the behavior of control modules.

- Adaptations: Adaptations involve adjusting specific settings within a control module to match the vehicle’s configuration or driver preferences.

- Coding: Coding involves changing the software code of a control module to enable or disable specific features or functions.

- Caution: Incorrect coding or adaptations can cause serious problems and may even damage the control module. It’s essential to proceed with caution and follow the correct procedures.

8.6 Communication Protocols

VAG vehicles use various communication protocols to allow the control modules to communicate with each other.

- CAN Bus (Controller Area Network): CAN bus is the most common communication protocol in modern vehicles. It’s a high-speed, two-wire bus that allows modules to share information.

- MOST Bus (Media Oriented Systems Transport): MOST bus is used for multimedia systems, such as audio and video.

- FlexRay: FlexRay is a high-speed communication protocol used in some advanced systems, such as adaptive cruise control and active suspension.

- DoIP (Diagnostics over Internet Protocol): DoIP is a newer protocol used for diagnostics and flashing over Ethernet.

Understanding these communication protocols is essential for diagnosing network-related problems.

9. Common VCDS Coding and Adaptation Procedures

VCDS is used for various coding and adaptation procedures. Here are some common examples:

9.1 Enabling Hidden Features

Many VAG vehicles have hidden features that can be enabled through coding. These features may include:

- Cornering Lights: Activating fog lights as cornering lights.

- Gauge Staging: Sweeping the instrument cluster needles on startup.

- Coming Home/Leaving Home Lights: Activating headlights or fog lights when unlocking or locking the vehicle.

- Emergency Brake Flashing: Flashing brake lights during hard braking.

9.2 Retrofitting Equipment

When retrofitting new equipment to a vehicle, such as a new radio or navigation system, coding and adaptations may be required to ensure proper operation.

9.3 Adjusting Lighting Settings

VCDS can be used to adjust various lighting settings, such as:

- Daytime Running Lights (DRL): Enabling or disabling DRLs and adjusting their brightness.

- Automatic Headlights: Adjusting the sensitivity of the automatic headlight sensor.

9.4 Adjusting Suspension Settings

Some VAG vehicles have adjustable suspension systems that can be configured using VCDS.

9.5 Key Coding

When replacing a lost or stolen key, VCDS can be used to code a new key to the vehicle.

9.6 ECU Flashing

ECU flashing involves replacing the software on a control module with a new version. This may be necessary to fix software bugs, improve performance, or install new features.

10. Safety Precautions When Using VCDS

Using VCDS involves risks, and it’s essential to take precautions to prevent damage to the vehicle or injury to yourself.

10.1 Use a Stable Power Supply

When performing coding, adaptations, or ECU flashing, it’s crucial to use a stable power supply to prevent voltage fluctuations. Voltage fluctuations can interrupt the process and may damage the control module.

10.2 Follow Instructions Carefully

Always follow the instructions in the vehicle’s repair manual or a reliable online resource. Incorrect coding or adaptations can cause serious problems.

10.3 Back Up Control Module Data

Before making any changes to a control module, it’s essential to back up the existing data. This will allow you to restore the module to its original state if something goes wrong.

10.4 Disconnect Unnecessary Accessories

Disconnect any unnecessary accessories, such as aftermarket stereos or GPS devices, before performing coding or adaptations. These accessories may interfere with the process.

10.5 Use a Genuine VCDS Interface

Using a non-genuine VCDS interface can damage the vehicle or provide inaccurate data. Always use a genuine Ross-Tech interface.

11. VAG 106 VCDS FAQ

Here are some frequently asked questions about using VCDS for car coding and diagnostics:

11.1 Is it safe to perform car coding myself?

Car coding can be safe if you follow instructions carefully and use a genuine VCDS interface. However, incorrect coding can cause problems, so it’s essential to proceed with caution.

11.2 What is involved in the remote support process?

Remote support involves connecting your VCDS interface to your vehicle and allowing a technician to remotely access your software to provide assistance.

11.3 How much does remote coding support cost?

The cost of remote coding support varies depending on the complexity of the task. Contact CAR-CODING.EDU.VN for a quote.

11.4 What types of vehicles and features do you support?

CAR-CODING.EDU.VN supports a wide range of VAG vehicles and features, including ECU programming, hidden feature activation, and fault code clearing.

11.5 What equipment do I need for remote support?

To receive remote support, you need a genuine VCDS interface, a laptop with internet access, and the VCDS software installed.

11.6 Can remote coding void my car’s warranty?

In some cases, coding changes can void your car’s warranty, especially if the changes are not approved by the manufacturer. Check with your dealer before performing any coding.

11.7 How long does a typical remote coding session take?

A typical remote coding session can take anywhere from 30 minutes to several hours, depending on the complexity of the task.

11.8 What if something goes wrong during the coding process?

If something goes wrong during the coding process, our technicians can help you restore the control module to its original state.

11.9 Can you help me find hidden features in my car?

Yes, CAR-CODING.EDU.VN can help you find hidden features in your car and enable them through coding.

11.10 Do you offer support for other diagnostic tools besides VCDS?

While we specialize in VCDS, we also have experience with other diagnostic tools and may be able to provide support for those as well. Contact us to inquire.

Are you ready to experience the power of expert car coding assistance? Contact CAR-CODING.EDU.VN today at Whatsapp +1 (641) 206-8880 or visit our website CAR-CODING.EDU.VN for immediate support and to schedule a remote coding session. Our office is located at 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States. Let us help you unlock your vehicle’s full potential!

VCDS Interface Connection for Remote Car Coding Assistance

VCDS Interface Connection for Remote Car Coding Assistance

VCDS Measuring Block Display for Fuel Rail Pressure Diagnostics

VCDS Measuring Block Display for Fuel Rail Pressure Diagnostics