Modern car coding can be complex, especially when dealing with seemingly simple issues like a persistent Vcds Washer Fluid Warning. At CAR-CODING.EDU.VN, we provide expert remote assistance to diagnose and resolve these issues efficiently. Benefit from our specialized knowledge in ECU programming, enabling hidden features, and comprehensive technical support.

Contents

- 1. Understanding the VCDS Washer Fluid Warning

- 1.1 What Does the Washer Fluid Warning Indicate?

- 1.2 Why Is This Warning Important?

- 1.3 How Does VCDS Help Diagnose the Issue?

- 2. Common Causes of a Persistent VCDS Washer Fluid Warning

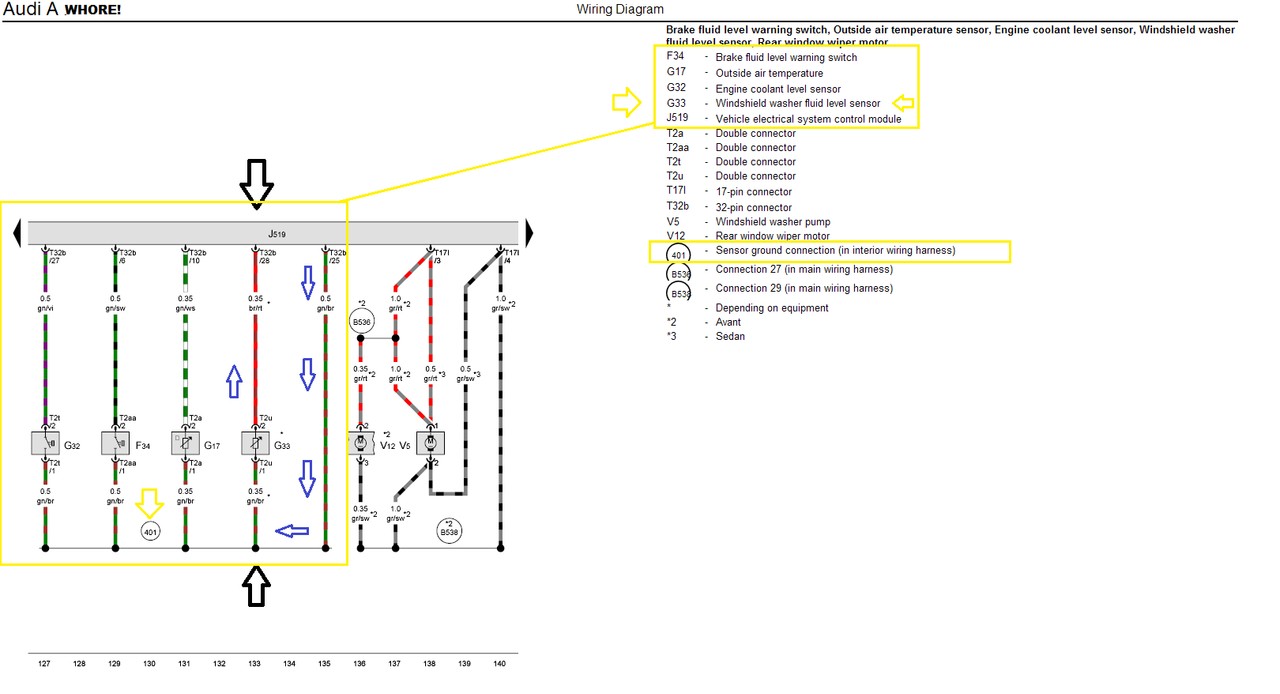

- 2.1 Faulty Washer Fluid Level Sensor (G33)

- 2.2 Wiring and Connection Issues

- 2.3 Low Washer Fluid Level

- 2.4 Faulty Body Control Module (BCM)

- 2.5 Clogged Washer Nozzles

- 3. Step-by-Step Diagnostic Procedure Using VCDS

- 3.1 Connecting VCDS to the Vehicle

- 3.2 Scanning for Fault Codes

- 3.3 Identifying Relevant Fault Codes

- 3.4 Reading Measuring Blocks

- 3.5 Performing Output Tests

- 4. Troubleshooting Steps for a Persistent Washer Fluid Warning

- 4.1 Inspecting the Washer Fluid Level Sensor

- 4.2 Checking Wiring and Connections

- 4.3 Testing Sensor Voltage

- 4.4 Verifying Ground Connection

- 4.5 Replacing the Washer Fluid Level Sensor

- 5. Advanced VCDS Coding for Washer Fluid System

- 5.1 Accessing the BCM Coding

- 5.2 Understanding Coding Options

- 5.3 Making Necessary Adjustments

- 5.4 Saving and Testing Coding Changes

- 6. Benefits of Professional Remote Coding Assistance from CAR-CODING.EDU.VN

- 6.1 Expert Guidance and Support

- 6.2 Remote Access and Coding

- 6.3 Safe and Reliable Coding

- 6.4 Cost-Effective Solution

- 6.5 Wide Range of Vehicle Support

- 7. Case Studies: Resolving Washer Fluid Warning with Remote Coding Assistance

- 7.1 Audi A4: Faulty Sensor Replacement

- 7.2 Volkswagen Golf: Wiring Harness Repair

- 7.3 Skoda Octavia: BCM Recoding

- 8. Maintaining Your Washer Fluid System

- 8.1 Using the Correct Washer Fluid

- 8.2 Regularly Checking Fluid Levels

- 8.3 Cleaning Washer Nozzles

- 8.4 Inspecting Hoses and Connections

- 8.5 Winterizing the System

- 9. Understanding VCDS (VAG-COM Diagnostic System)

- 9.1 What is VCDS?

- 9.2 Key Features of VCDS

- 9.3 How VCDS Enhances Vehicle Diagnostics

- 10. The Role of the Body Control Module (BCM) in Washer Fluid System

- 10.1 What is the Body Control Module (BCM)?

- 10.2 BCM Functions in the Washer Fluid System

- 10.3 How the BCM Affects Washer Fluid Warning

- 11. Exploring Washer Fluid Level Sensor (G33)

- 11.1 What is the Washer Fluid Level Sensor (G33)?

- 11.2 Functionality of the G33 Sensor

- 11.3 Common Issues with the G33 Sensor

- 12. The Importance of Correct Wiring and Connections

- 12.1 Why Wiring Matters in the Washer Fluid System

- 12.2 Common Wiring Problems

- 12.3 How to Check Wiring and Connections

- 13. Understanding and Clearing Fault Codes Related to Washer Fluid

- 13.1 What are Fault Codes?

- 13.2 Common Fault Codes Related to Washer Fluid

- 13.3 Using VCDS to Read and Clear Fault Codes

- 14. Exploring Coding Options in VCDS for Washer Fluid System

- 14.1 What is Coding in VCDS?

- 14.2 Coding Options for Washer Fluid System

- 14.3 How to Access and Modify Coding Options

- 15. Utilizing Measuring Blocks in VCDS for Sensor Diagnostics

- 15.1 What are Measuring Blocks?

- 15.2 Measuring Blocks for Washer Fluid Level Sensor

- 15.3 How to Use Measuring Blocks for Diagnostics

- 16. Performing Output Tests with VCDS to Verify System Functionality

- 16.1 What are Output Tests?

- 16.2 Output Tests for Washer Fluid System

- 16.3 How to Perform Output Tests

- 17. Addressing Common Misconceptions About Washer Fluid Warnings

- 17.1 Misconception: “It’s Just a Low Fluid Level”

- 17.2 Misconception: “Any Washer Fluid Will Do”

- 17.3 Misconception: “The Sensor Always Needs Replacing”

- 17.4 Misconception: “Coding Can’t Fix the Problem”

- 18. Advanced Techniques for Diagnosing Intermittent Washer Fluid Warnings

- 18.1 Understanding Intermittent Issues

- 18.2 Techniques for Diagnosing Intermittent Warnings

- 18.3 Tools for Diagnosing Intermittent Issues

- 19. How to Handle Complex Coding Scenarios with CAR-CODING.EDU.VN Assistance

- 19.1 Understanding Complex Coding

- 19.2 Scenarios Requiring Professional Assistance

- 19.3 Benefits of CAR-CODING.EDU.VN Assistance

- 20. The Future of Car Coding and Washer Fluid System Diagnostics

- 20.1 Emerging Technologies

- 20.2 Future Trends in Washer Fluid System Diagnostics

- 20.3 How CAR-CODING.EDU.VN Stays Ahead

- 21. FAQ: Addressing Common Questions About VCDS Washer Fluid Warning

- 21.1 Is It Safe to Perform Coding on My Car’s ECU?

- 21.2 How Does Remote Support Work?

- 21.3 What is the Cost of Remote Coding Assistance?

- 21.4 What Types of Vehicles Do You Support?

- 21.5 What Kind of Features Can Be Coded?

- 21.6 What Equipment Do I Need for Remote Coding?

- 21.7 How Long Does Remote Coding Take?

- 21.8 What If Something Goes Wrong During Coding?

- 21.9 Can Coding Void My Car’s Warranty?

- 21.10 How Can I Get Started with Remote Coding Assistance?

1. Understanding the VCDS Washer Fluid Warning

The VCDS (VAG-COM Diagnostic System) washer fluid warning indicates a problem with the washer fluid level sensor or the associated wiring in Volkswagen Audi Group (VAG) vehicles. It’s a common issue that can arise from several factors, necessitating a systematic approach to diagnosis and repair.

1.1 What Does the Washer Fluid Warning Indicate?

The warning typically suggests that the washer fluid level is low, but it can also be triggered by a malfunctioning sensor, wiring issues, or even a faulty Body Control Module (BCM).

1.2 Why Is This Warning Important?

Ignoring this warning can lead to an empty washer fluid reservoir, impairing visibility and posing a safety risk, especially during inclement weather. Proper functionality of the windshield washer system is crucial for maintaining a clear view of the road.

1.3 How Does VCDS Help Diagnose the Issue?

VCDS allows technicians to read fault codes, monitor sensor values, and perform output tests to pinpoint the exact cause of the warning. This diagnostic capability is essential for efficient and accurate repairs.

2. Common Causes of a Persistent VCDS Washer Fluid Warning

Several factors can lead to a persistent washer fluid warning, even after refilling the reservoir. Identifying these causes is the first step in resolving the issue.

2.1 Faulty Washer Fluid Level Sensor (G33)

The most common culprit is a defective washer fluid level sensor. Over time, these sensors can fail due to corrosion, debris accumulation, or electrical damage.

2.2 Wiring and Connection Issues

Damaged or corroded wiring, loose connections, or shorts in the wiring harness can disrupt the signal from the sensor to the BCM, triggering the warning.

2.3 Low Washer Fluid Level

While seemingly obvious, a low washer fluid level is a frequent cause. Ensure the reservoir is filled to the correct level and check for any leaks.

2.4 Faulty Body Control Module (BCM)

In rare cases, a malfunctioning BCM can incorrectly interpret the sensor signal, leading to a false warning.

2.5 Clogged Washer Nozzles

Clogged nozzles can cause the system to work harder, potentially affecting sensor readings or fluid levels over time.

3. Step-by-Step Diagnostic Procedure Using VCDS

Diagnosing a persistent washer fluid warning requires a methodical approach using VCDS to identify the root cause accurately.

3.1 Connecting VCDS to the Vehicle

Connect the VCDS interface to the vehicle’s OBD-II port and ensure a stable connection. Turn on the ignition but do not start the engine.

3.2 Scanning for Fault Codes

Use VCDS to scan all control modules for fault codes. Pay close attention to codes related to the BCM or the washer fluid system.

3.3 Identifying Relevant Fault Codes

Look for specific fault codes such as:

- 00526 – Brake Light Switch-F

- 00907 – Intervention load Management

These codes can provide valuable clues about the underlying issue.

3.4 Reading Measuring Blocks

Access the measuring blocks in the BCM to monitor the washer fluid level sensor’s output. Observe the sensor’s readings as you fill and empty the washer fluid reservoir.

3.5 Performing Output Tests

Use VCDS to perform output tests on the washer pump and other related components to verify their functionality.

4. Troubleshooting Steps for a Persistent Washer Fluid Warning

Once you’ve gathered diagnostic information, follow these troubleshooting steps to address the issue.

4.1 Inspecting the Washer Fluid Level Sensor

Visually inspect the sensor for any signs of damage or corrosion. Clean the sensor and its contacts, and test its resistance using a multimeter.

4.2 Checking Wiring and Connections

Carefully examine the wiring harness and connectors associated with the washer fluid level sensor. Look for any signs of damage, corrosion, or loose connections. Repair or replace any damaged wiring.

4.3 Testing Sensor Voltage

Use a multimeter to test the voltage at the sensor connector. Ensure that the sensor is receiving the correct voltage from the BCM.

4.4 Verifying Ground Connection

Check the ground connection for the washer fluid level sensor. A poor ground connection can cause inaccurate readings and trigger the warning.

4.5 Replacing the Washer Fluid Level Sensor

If the sensor is faulty, replace it with a new, OEM-quality sensor. Ensure that the new sensor is properly installed and connected.

5. Advanced VCDS Coding for Washer Fluid System

In some cases, coding adjustments may be necessary to resolve the washer fluid warning, especially after replacing components or performing other repairs.

5.1 Accessing the BCM Coding

Use VCDS to access the coding section of the BCM. This will allow you to make adjustments to the system’s configuration.

5.2 Understanding Coding Options

Familiarize yourself with the available coding options related to the washer fluid system. Refer to the vehicle’s repair manual or online resources for guidance.

5.3 Making Necessary Adjustments

Make any necessary coding adjustments to ensure that the BCM is correctly interpreting the sensor’s signal. Be cautious when making changes, as incorrect coding can lead to other issues.

5.4 Saving and Testing Coding Changes

After making coding changes, save the new configuration and test the washer fluid system to ensure that the warning has been resolved.

6. Benefits of Professional Remote Coding Assistance from CAR-CODING.EDU.VN

For complex coding tasks or when facing persistent issues, professional remote coding assistance from CAR-CODING.EDU.VN can provide invaluable support.

6.1 Expert Guidance and Support

Our team of experienced technicians can provide expert guidance and support throughout the diagnostic and coding process. We can help you identify the root cause of the issue and implement the correct solution.

6.2 Remote Access and Coding

We can remotely access your vehicle’s control modules and perform coding adjustments on your behalf. This eliminates the need to visit a dealership or specialized repair shop.

6.3 Safe and Reliable Coding

We use industry-best practices and follow strict safety protocols to ensure that all coding changes are performed safely and reliably.

6.4 Cost-Effective Solution

Remote coding assistance can be a more cost-effective solution compared to traditional repair methods, saving you time and money.

6.5 Wide Range of Vehicle Support

We offer remote coding assistance for a wide range of VAG vehicles, including Audi, Volkswagen, Seat, and Skoda models.

7. Case Studies: Resolving Washer Fluid Warning with Remote Coding Assistance

Here are a few examples of how remote coding assistance from CAR-CODING.EDU.VN has helped resolve persistent washer fluid warnings.

7.1 Audi A4: Faulty Sensor Replacement

A customer replaced a faulty washer fluid level sensor in their Audi A4, but the warning persisted. Our technicians remotely accessed the vehicle’s BCM and performed coding adjustments to calibrate the new sensor, resolving the issue.

7.2 Volkswagen Golf: Wiring Harness Repair

A Volkswagen Golf owner had repaired a damaged wiring harness, but the washer fluid warning remained. We remotely inspected the coding and identified an incorrect setting, which we corrected to clear the warning.

7.3 Skoda Octavia: BCM Recoding

After a BCM replacement in a Skoda Octavia, the washer fluid warning appeared. Our team remotely recoded the BCM to match the vehicle’s specifications, eliminating the warning.

8. Maintaining Your Washer Fluid System

Proper maintenance of your washer fluid system can help prevent issues and ensure its optimal performance.

8.1 Using the Correct Washer Fluid

Use a high-quality washer fluid that is specifically designed for your vehicle. Avoid using plain water, as it can freeze and damage the system.

8.2 Regularly Checking Fluid Levels

Check the washer fluid level regularly and refill as needed. This will help prevent the system from running dry and causing damage.

8.3 Cleaning Washer Nozzles

Clean the washer nozzles regularly to remove any debris or clogs. Use a small needle or compressed air to clear any obstructions.

8.4 Inspecting Hoses and Connections

Inspect the hoses and connections for any signs of leaks or damage. Replace any damaged components promptly.

8.5 Winterizing the System

In cold climates, use a washer fluid with antifreeze to prevent the system from freezing.

9. Understanding VCDS (VAG-COM Diagnostic System)

VCDS is a powerful diagnostic tool used for Volkswagen Audi Group (VAG) vehicles, providing in-depth access to vehicle systems and allowing for advanced diagnostics and coding.

9.1 What is VCDS?

VCDS (VAG-COM Diagnostic System) is a software and hardware package developed by Ross-Tech, designed for diagnosing and modifying the control modules in VAG vehicles, including Volkswagen, Audi, Seat, and Skoda.

9.2 Key Features of VCDS

- Fault Code Reading and Clearing: Retrieves and clears Diagnostic Trouble Codes (DTCs) from various control modules.

- Live Data Monitoring: Displays real-time data from sensors and systems within the vehicle.

- Output Tests: Activates and tests various components to verify their functionality.

- Coding and Adaptation: Allows for modifying control module settings to customize vehicle behavior and enable features.

- Basic Settings: Performs calibrations and adaptations of various systems, such as throttle body alignment.

9.3 How VCDS Enhances Vehicle Diagnostics

VCDS provides a comprehensive view of the vehicle’s electronic systems, enabling technicians to quickly identify and address issues. Its ability to access live data, perform output tests, and modify coding makes it an indispensable tool for advanced diagnostics and repairs.

10. The Role of the Body Control Module (BCM) in Washer Fluid System

The Body Control Module (BCM) plays a central role in managing various vehicle functions, including the washer fluid system.

10.1 What is the Body Control Module (BCM)?

The BCM is an electronic control unit (ECU) responsible for controlling and monitoring various body-related functions in a vehicle, such as lighting, wipers, door locks, and the washer fluid system.

10.2 BCM Functions in the Washer Fluid System

- Monitoring Fluid Level: Receives input from the washer fluid level sensor and triggers a warning if the fluid level is low.

- Controlling Washer Pump: Activates the washer pump when the driver requests washer fluid.

- Managing Wiper Operation: Coordinates the operation of the windshield wipers with the washer pump.

- Providing Diagnostic Information: Stores fault codes related to the washer fluid system and provides diagnostic information to technicians.

10.3 How the BCM Affects Washer Fluid Warning

A malfunctioning BCM can lead to false washer fluid warnings, incorrect pump operation, or other issues with the system. Proper BCM coding and diagnostics are essential for resolving these problems.

11. Exploring Washer Fluid Level Sensor (G33)

The washer fluid level sensor, often referred to as G33, is a critical component in the washer fluid system, responsible for monitoring the fluid level and alerting the driver when it is low.

11.1 What is the Washer Fluid Level Sensor (G33)?

The G33 sensor is a float-type sensor located inside the washer fluid reservoir. It uses a float and a magnetic switch to detect the fluid level and send a signal to the BCM.

11.2 Functionality of the G33 Sensor

- Fluid Level Detection: The float rises and falls with the fluid level. When the fluid level drops below a certain point, the float activates a magnetic switch.

- Signal Transmission: The magnetic switch sends a signal to the BCM, indicating that the fluid level is low.

- Warning Activation: The BCM then activates the washer fluid warning on the instrument cluster.

11.3 Common Issues with the G33 Sensor

- Sensor Failure: The sensor can fail due to corrosion, debris accumulation, or electrical damage.

- Float Issues: The float can become stuck or damaged, leading to inaccurate readings.

- Wiring Problems: Damaged wiring or loose connections can disrupt the signal from the sensor to the BCM.

12. The Importance of Correct Wiring and Connections

Proper wiring and secure connections are crucial for the reliable operation of the washer fluid system.

12.1 Why Wiring Matters in the Washer Fluid System

The wiring harness and connectors provide the electrical pathways for the washer fluid level sensor and the washer pump. Any issues with the wiring can disrupt the system’s operation.

12.2 Common Wiring Problems

- Corrosion: Corrosion can build up on connectors and wiring, leading to poor connections and signal loss.

- Damage: Wires can become damaged due to wear and tear, exposure to the elements, or accidental damage.

- Loose Connections: Connectors can become loose over time, causing intermittent issues.

12.3 How to Check Wiring and Connections

- Visual Inspection: Inspect the wiring harness and connectors for any signs of damage or corrosion.

- Continuity Testing: Use a multimeter to test the continuity of the wires and ensure that there are no breaks or shorts.

- Voltage Testing: Test the voltage at the sensor connector to ensure that the sensor is receiving the correct voltage.

- Cleaning Connectors: Clean any corroded connectors with a wire brush or contact cleaner.

13. Understanding and Clearing Fault Codes Related to Washer Fluid

Fault codes provide valuable information about issues within the washer fluid system, and understanding how to read and clear them is essential for effective diagnostics.

13.1 What are Fault Codes?

Fault codes, also known as Diagnostic Trouble Codes (DTCs), are codes stored in the vehicle’s control modules that indicate a problem has been detected.

13.2 Common Fault Codes Related to Washer Fluid

- B104D15 – Washer Fluid Level Sensor: Open or Short to Ground: Indicates an issue with the sensor circuit.

- B104D11 – Washer Fluid Level Sensor: Short to Plus: Indicates a short circuit in the sensor circuit.

- B104D00 – Washer Fluid Level Sensor: General Failure: Indicates a general failure of the sensor.

13.3 Using VCDS to Read and Clear Fault Codes

- Connect VCDS: Connect the VCDS interface to the vehicle’s OBD-II port.

- Scan for Fault Codes: Use VCDS to scan all control modules for fault codes.

- Identify Relevant Codes: Look for fault codes related to the BCM or the washer fluid system.

- Clear Fault Codes: After addressing the issue, use VCDS to clear the fault codes.

- Verify Repair: Test the system to ensure that the fault codes do not return.

14. Exploring Coding Options in VCDS for Washer Fluid System

VCDS provides various coding options that allow technicians to customize the behavior of the washer fluid system.

14.1 What is Coding in VCDS?

Coding in VCDS involves modifying the software settings in the vehicle’s control modules to customize various functions and features.

14.2 Coding Options for Washer Fluid System

- Washer Fluid Level Warning Threshold: Adjust the level at which the washer fluid warning is triggered.

- Washer Pump Activation Delay: Adjust the delay between when the driver requests washer fluid and when the pump activates.

- Washer Fluid Heater Activation: Enable or disable the washer fluid heater, if equipped.

14.3 How to Access and Modify Coding Options

- Connect VCDS: Connect the VCDS interface to the vehicle’s OBD-II port.

- Access Control Module: Use VCDS to access the control module related to the washer fluid system (typically the BCM).

- Enter Coding Section: Navigate to the coding section of the control module.

- Modify Coding: Make the necessary coding adjustments.

- Save Coding: Save the new coding settings.

- Test System: Test the system to ensure that the coding changes have been applied correctly.

15. Utilizing Measuring Blocks in VCDS for Sensor Diagnostics

Measuring blocks in VCDS provide real-time data from sensors and systems, enabling technicians to diagnose issues more effectively.

15.1 What are Measuring Blocks?

Measuring blocks are groups of data values that can be monitored in real-time using VCDS. These values provide information about the performance of various sensors and systems.

15.2 Measuring Blocks for Washer Fluid Level Sensor

- Washer Fluid Level: Displays the current fluid level as measured by the sensor.

- Sensor Voltage: Displays the voltage output from the sensor.

- Sensor Status: Indicates whether the sensor is active or inactive.

15.3 How to Use Measuring Blocks for Diagnostics

- Connect VCDS: Connect the VCDS interface to the vehicle’s OBD-II port.

- Access Control Module: Use VCDS to access the control module related to the washer fluid system (typically the BCM).

- Enter Measuring Blocks: Navigate to the measuring blocks section of the control module.

- Monitor Data: Monitor the data values related to the washer fluid level sensor.

- Analyze Data: Analyze the data to identify any issues with the sensor or the system.

16. Performing Output Tests with VCDS to Verify System Functionality

Output tests in VCDS allow technicians to activate and test various components, verifying their functionality and helping to pinpoint issues.

16.1 What are Output Tests?

Output tests are diagnostic procedures that allow technicians to activate specific components in the vehicle to verify their functionality.

16.2 Output Tests for Washer Fluid System

- Washer Pump Activation: Activates the washer pump to test its operation.

- Washer Nozzle Activation: Activates the washer nozzles to test their spray pattern.

16.3 How to Perform Output Tests

- Connect VCDS: Connect the VCDS interface to the vehicle’s OBD-II port.

- Access Control Module: Use VCDS to access the control module related to the washer fluid system (typically the BCM).

- Enter Output Tests: Navigate to the output tests section of the control module.

- Select Test: Select the desired output test (e.g., washer pump activation).

- Run Test: Run the test and observe the component’s behavior.

- Analyze Results: Analyze the results to determine if the component is functioning correctly.

17. Addressing Common Misconceptions About Washer Fluid Warnings

Several misconceptions surround washer fluid warnings, which can lead to incorrect diagnoses and ineffective repairs.

17.1 Misconception: “It’s Just a Low Fluid Level”

While a low fluid level is a common cause, it’s essential to investigate further if the warning persists after refilling the reservoir. The issue may be a faulty sensor or wiring problem.

17.2 Misconception: “Any Washer Fluid Will Do”

Using the wrong type of washer fluid can damage the system. Always use a high-quality washer fluid that is specifically designed for your vehicle.

17.3 Misconception: “The Sensor Always Needs Replacing”

While the sensor is a common failure point, other components, such as the wiring or the BCM, can also cause the warning. Thorough diagnostics are essential before replacing the sensor.

17.4 Misconception: “Coding Can’t Fix the Problem”

In some cases, coding adjustments are necessary to resolve the washer fluid warning, especially after replacing components or performing other repairs.

18. Advanced Techniques for Diagnosing Intermittent Washer Fluid Warnings

Intermittent washer fluid warnings can be particularly challenging to diagnose, requiring advanced techniques and a systematic approach.

18.1 Understanding Intermittent Issues

Intermittent issues occur sporadically, making them difficult to identify and diagnose. They can be caused by loose connections, damaged wiring, or faulty components that only fail under certain conditions.

18.2 Techniques for Diagnosing Intermittent Warnings

- Detailed Visual Inspection: Conduct a thorough visual inspection of the wiring harness, connectors, and components.

- Stress Testing: Apply stress to the wiring and connectors by wiggling them or applying slight pressure. Monitor the sensor readings in VCDS to see if the warning appears.

- Data Logging: Use VCDS to log data from the washer fluid level sensor over an extended period. This can help identify patterns or conditions that trigger the warning.

- Component Isolation: Isolate individual components to determine if they are causing the issue. For example, disconnect the sensor and see if the warning disappears.

18.3 Tools for Diagnosing Intermittent Issues

- Multimeter: Use a multimeter to test the continuity and voltage of the wiring and connectors.

- VCDS: Use VCDS to monitor sensor readings, perform output tests, and log data.

- Wiring Diagrams: Refer to the vehicle’s wiring diagrams to trace the wiring and identify potential problem areas.

19. How to Handle Complex Coding Scenarios with CAR-CODING.EDU.VN Assistance

Complex coding scenarios can arise when dealing with advanced vehicle systems or when performing custom modifications.

19.1 Understanding Complex Coding

Complex coding involves making changes to multiple control modules or performing advanced adaptations to customize vehicle behavior.

19.2 Scenarios Requiring Professional Assistance

- Retrofitting Components: Retrofitting components, such as adding a new feature or upgrading an existing system, often requires complex coding.

- Custom Modifications: Performing custom modifications, such as changing the behavior of the lighting system or the engine control unit, can involve advanced coding techniques.

- Troubleshooting Coding Issues: Troubleshooting coding issues, such as incorrect coding or conflicts between different modules, can require specialized knowledge and tools.

19.3 Benefits of CAR-CODING.EDU.VN Assistance

- Expertise: Our team of experienced technicians has the expertise to handle complex coding scenarios.

- Remote Access: We can remotely access your vehicle’s control modules and perform coding adjustments on your behalf.

- Safe and Reliable Coding: We use industry-best practices and follow strict safety protocols to ensure that all coding changes are performed safely and reliably.

20. The Future of Car Coding and Washer Fluid System Diagnostics

The field of car coding and diagnostics is constantly evolving, with new technologies and techniques emerging all the time.

20.1 Emerging Technologies

- Over-the-Air (OTA) Updates: OTA updates allow vehicle manufacturers to remotely update the software in the vehicle’s control modules, including the BCM.

- Artificial Intelligence (AI): AI is being used to develop more advanced diagnostic tools that can automatically identify and diagnose issues.

- Cloud-Based Diagnostics: Cloud-based diagnostics allow technicians to access diagnostic information and coding resources from anywhere with an internet connection.

20.2 Future Trends in Washer Fluid System Diagnostics

- More Advanced Sensors: Washer fluid level sensors are becoming more advanced, with the ability to detect not only the fluid level but also the quality of the fluid.

- Integration with Advanced Driver Assistance Systems (ADAS): The washer fluid system is becoming increasingly integrated with ADAS, such as automatic emergency braking and lane keeping assist.

- Remote Diagnostics and Coding: Remote diagnostics and coding are becoming more common, allowing technicians to diagnose and repair vehicles from anywhere in the world.

Washer Fluid Level Sensor

Washer Fluid Level Sensor

20.3 How CAR-CODING.EDU.VN Stays Ahead

At CAR-CODING.EDU.VN, we are committed to staying at the forefront of these advancements by continuously training our technicians and investing in the latest tools and technologies.

21. FAQ: Addressing Common Questions About VCDS Washer Fluid Warning

Here are some frequently asked questions about the VCDS washer fluid warning, along with detailed answers to help you better understand the issue.

21.1 Is It Safe to Perform Coding on My Car’s ECU?

Yes, coding is generally safe if performed by experienced technicians following proper procedures. At CAR-CODING.EDU.VN, we prioritize safety and use industry-best practices to ensure reliable coding changes.

21.2 How Does Remote Support Work?

Remote support involves connecting to your vehicle’s control modules via a secure internet connection. Our technicians can then perform diagnostics, coding, and adaptations remotely, saving you time and money.

21.3 What is the Cost of Remote Coding Assistance?

The cost of remote coding assistance varies depending on the complexity of the task. Contact us for a personalized quote based on your specific needs.

21.4 What Types of Vehicles Do You Support?

We offer remote coding assistance for a wide range of VAG vehicles, including Audi, Volkswagen, Seat, and Skoda models. Contact us to confirm support for your specific vehicle.

21.5 What Kind of Features Can Be Coded?

Many features can be coded, including enabling hidden features, customizing vehicle behavior, and retrofitting components. Contact us to learn more about the available coding options for your vehicle.

21.6 What Equipment Do I Need for Remote Coding?

You’ll need a VCDS interface, a laptop with a stable internet connection, and the VCDS software installed. We can provide guidance on selecting and setting up the necessary equipment.

21.7 How Long Does Remote Coding Take?

The duration of remote coding varies depending on the complexity of the task. Simple coding changes can be completed in a few minutes, while more complex coding may take longer.

21.8 What If Something Goes Wrong During Coding?

Our technicians take precautions to prevent issues during coding. In the rare event that something goes wrong, we have procedures in place to restore the vehicle to its original state.

21.9 Can Coding Void My Car’s Warranty?

Coding can potentially void your car’s warranty if it is not performed by an authorized technician or if it results in damage to the vehicle. Consult with your dealer or warranty provider for more information.

21.10 How Can I Get Started with Remote Coding Assistance?

To get started with remote coding assistance, simply contact us via WhatsApp at +1 (641) 206-8880 or visit our website at CAR-CODING.EDU.VN. Our team will be happy to assist you with your coding needs. Our US support office is located at 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States.

Don’t let a persistent VCDS washer fluid warning keep you from enjoying your vehicle. Contact CAR-CODING.EDU.VN today for expert remote coding assistance and get your washer fluid system working properly again! Reach out now via WhatsApp at +1 (641) 206-8880 or visit CAR-CODING.EDU.VN. We’re here to help you resolve your car coding issues quickly and safely! Let our expertise at CAR-CODING.EDU.VN provide solutions.