Modern car battery replacement requires coding, and if you’re struggling with the correct Vcds Battery Code for your new car battery, especially when the battery lacks a clear BEM code or the numbers don’t match VCDS requirements, CAR-CODING.EDU.VN offers expert remote support to ensure accurate coding and optimal vehicle performance. Our expert assistance can help you to avoid potential issues caused by incorrect coding, such as battery charging problems, electrical system malfunctions, or even ECU damage, which might occur during battery replacement.

Contents

- 1. Understanding VCDS Battery Coding and Its Importance

- Why is Battery Coding Necessary?

- Consequences of Incorrect Battery Coding

- 2. Decoding Battery Information: VIN, Part Number, and More

- Understanding Battery Specifications

- Locating Key Information on the Battery

- Common Challenges in Decoding Battery Information

- 3. Step-by-Step Guide to VCDS Battery Coding

- Prerequisites for VCDS Battery Coding

- Connecting VCDS to the Vehicle

- Entering New Battery Information

- Troubleshooting Common Issues

- Seeking Professional Assistance

- 4. Common Mistakes to Avoid During Battery Coding

- Using Incorrect Battery Information

- Ignoring Battery Specifications

- Failing to Follow the Correct Procedure

- Using Incompatible Tools

- Interrupting the Coding Process

- Ignoring Error Messages

- Overlooking Firmware Updates

- 5. When to Seek Professional Remote Assistance

- Complex or Unclear Battery Information

- Unfamiliarity with VCDS Software

- Troubleshooting Difficult Issues

- High-Value or Complex Vehicles

- Lack of Confidence

- Time Constraints

- Warranty Concerns

- 6. The Benefits of Using CAR-CODING.EDU.VN for Remote Assistance

- Expertise and Experience

- Remote Convenience

- Cost-Effectiveness

- Time Savings

- Error Prevention

- Support and Guidance

- Warranty Protection

- 7. Detailed Explanation: CAN Bus, MOST, FlexRay, and DoIP

- CAN Bus (Controller Area Network)

- MOST (Media Oriented Systems Transport)

- FlexRay

- DoIP (Diagnostics over Internet Protocol)

- 8. Safety Precautions During VCDS Battery Coding

- Working in a Well-Ventilated Area

- Wearing Protective Gear

- Disconnecting the Battery Properly

- Avoiding Sparks

- Using Insulated Tools

- Proper Disposal of Old Batteries

- Consulting a Professional

- 9. Example Cases: Successful VCDS Battery Coding with Remote Support

- Case 1: Coding an AGM Battery on an Audi A6

- Case 2: Troubleshooting Communication Errors on a VW Golf

- Case 3: Coding a Battery Without a BEM Code on a BMW 5 Series

- Case 4: Solving Battery Drain Issues on a Mercedes-Benz C-Class

- Case 5: Coding a High-Capacity Battery on a Land Rover Range Rover

- 10. Frequently Asked Questions (FAQ) About VCDS Battery Coding

- Q1: Is it safe to perform VCDS battery coding myself?

- Q2: What is the process for remote assistance with CAR-CODING.EDU.VN?

- Q3: How much does remote VCDS battery coding cost?

- Q4: What types of vehicles and batteries are supported?

- Q5: What equipment is required on my end for remote assistance?

- Q6: How long does the remote battery coding process take?

- Q7: What if I encounter issues during the coding process?

- Q8: Will coding a new battery void my vehicle’s warranty?

- Q9: What happens if the coding is not done correctly?

- Q10: How can I schedule remote assistance with CAR-CODING.EDU.VN?

1. Understanding VCDS Battery Coding and Its Importance

VCDS battery coding is the process of informing your vehicle’s Battery Management System (BMS) that a new battery has been installed. This coding ensures the car charges the battery correctly, extends battery life, and optimizes the vehicle’s electrical system performance. Proper coding is crucial because modern vehicles use sophisticated charging algorithms tailored to the battery’s specific characteristics.

Why is Battery Coding Necessary?

Modern vehicles require battery coding for several reasons:

- Optimal Charging: Coding ensures the vehicle’s charging system is optimized for the new battery’s specifications, preventing overcharging or undercharging.

- Extended Battery Life: Proper charging cycles, managed by the BMS, can significantly extend the life of the new battery.

- Electrical System Performance: Correct battery coding helps maintain stable voltage levels, ensuring all electrical components function correctly.

- Error Prevention: Coding helps prevent error messages related to battery performance and charging issues.

Consequences of Incorrect Battery Coding

Failing to code a new battery or entering incorrect information can lead to:

- Reduced Battery Life: Inefficient charging cycles can shorten the battery’s lifespan.

- Charging Problems: The battery may not charge fully or may overcharge, causing damage.

- Electrical Issues: Unstable voltage can affect various electrical components, leading to malfunctions.

- Warning Lights: The vehicle may display warning lights related to battery or electrical system issues.

2. Decoding Battery Information: VIN, Part Number, and More

Identifying the correct battery information is the first step in the VCDS coding process. Understanding the various codes and numbers on the battery can be confusing, but each piece of information plays a crucial role.

Understanding Battery Specifications

Before attempting to code a new battery, it’s essential to understand the key specifications and codes printed on the battery label:

- Battery Type: Lead-acid, AGM (Absorbent Glass Mat), or EFB (Enhanced Flooded Battery). AGM and EFB batteries are common in modern vehicles due to their improved performance and durability.

- Capacity (Ah): Ampere-hour rating indicates the battery’s ability to store electrical charge. It’s crucial to match the new battery’s Ah rating to the original specification.

- Cold Cranking Amps (CCA): CCA measures the battery’s ability to start the engine in cold conditions.

- Part Number: The manufacturer’s part number is a unique identifier for the battery model.

- Vendor Code: A code that identifies the battery manufacturer (e.g., Varta, Bosch, Exide).

- Serial Number: A unique serial number assigned to each individual battery.

- BEM Code: (Battery Energy Management Code): A specific code used by some manufacturers (like VAG) to identify battery parameters. This is often a QR code that can be scanned.

Locating Key Information on the Battery

The required information for VCDS coding can typically be found on the battery label. Here’s what to look for:

- Part Number: Usually a series of numbers and letters.

- Vendor Code: Often a short code or abbreviation indicating the manufacturer.

- Serial Number: A longer sequence of numbers and letters, often unique to the battery.

- BEM Code: This may be printed as a QR code or a string of characters.

Common Challenges in Decoding Battery Information

Sometimes, obtaining the correct information can be challenging:

- Missing BEM Code: Some aftermarket batteries may not have a BEM code, requiring manual entry of the part number, vendor code, and serial number.

- Incorrect Length: The codes on the battery may not match the expected length for VCDS (e.g., VCDS may require 11 digits for the part number, while the battery has 12).

- Confusing Numbers: Multiple codes and numbers on the battery can be confusing, making it difficult to identify the correct ones.

If you encounter these issues, CAR-CODING.EDU.VN can assist in decoding the battery information and determining the correct VCDS coding parameters.

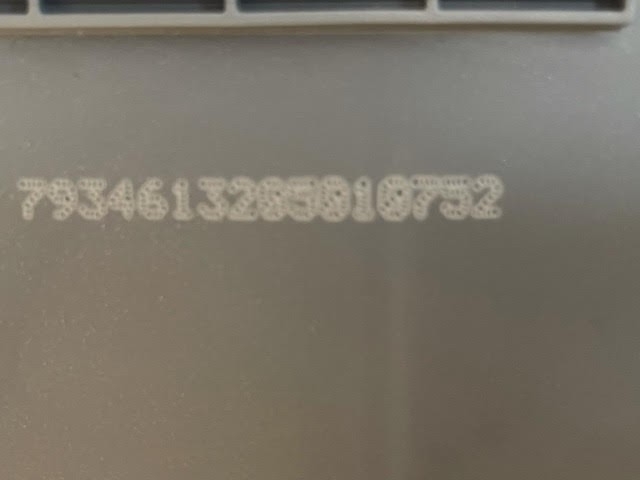

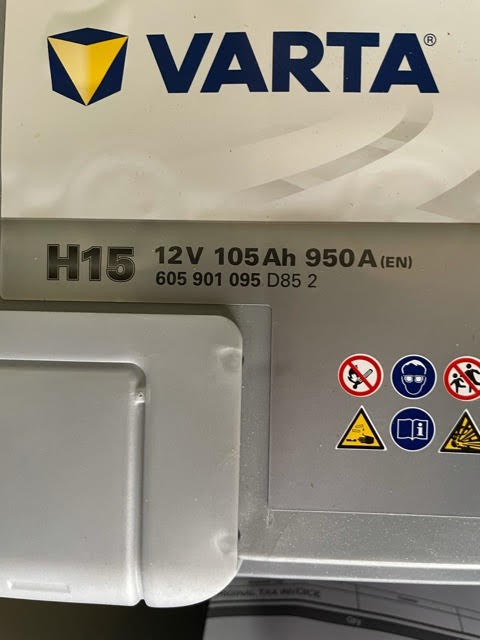

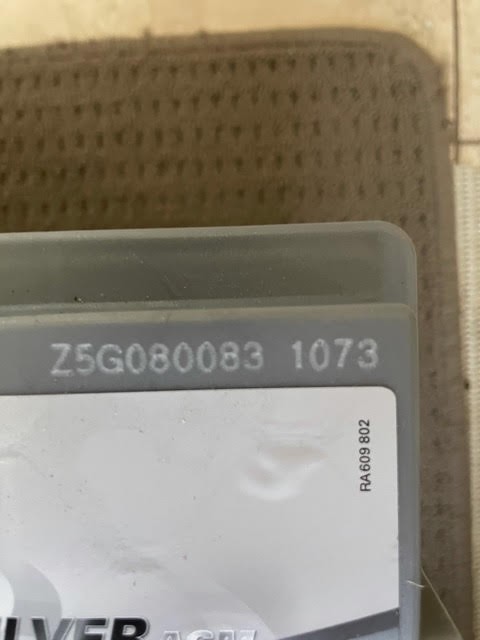

Varta Battery Label

Varta Battery Label

An example of a Varta battery label with various codes and numbers that might be needed for VCDS battery coding

3. Step-by-Step Guide to VCDS Battery Coding

Using VCDS (Vag-Com Diagnostic System) for battery coding involves a systematic process to ensure the vehicle’s Battery Management System (BMS) correctly recognizes the new battery. Here’s a detailed guide:

Prerequisites for VCDS Battery Coding

Before starting the coding process, ensure you have the following:

- VCDS Software: The latest version of the VCDS software installed on your laptop.

- VCDS Interface Cable: A genuine Ross-Tech VCDS interface cable.

- Laptop: A laptop with a stable internet connection and sufficient battery life.

- Battery Information: Gather all necessary information from the new battery label, including the part number, vendor code, and serial number.

Connecting VCDS to the Vehicle

- Connect the VCDS cable: Plug the VCDS interface cable into the OBD-II port of your vehicle (usually located under the dashboard).

- Turn on the ignition: Turn the ignition key to the “ON” position without starting the engine.

- Launch VCDS: Open the VCDS software on your laptop.

- Select Control Module:

- Click on “Select” to choose a control module.

- Select “61 – Battery Regulation”.

- The system will connect to the Battery Regulation module, displaying the current battery information.

Entering New Battery Information

- Access Adaptation:

- Click on “Adaptation – 10”.

- In the channel selection, look for “Battery Identification” or a similar description.

- Enter New Values:

- You will typically need to enter three values:

- Battery Part Number: A series of numbers and letters (usually 11 digits).

- Battery Vendor Code: A 3-digit code identifying the manufacturer.

- Battery Serial Number: A unique serial number for the battery (usually 10 digits).

- Enter the correct values from the new battery label into the corresponding fields.

- You will typically need to enter three values:

- Save the Changes:

- Click on “Do It!” to save the new battery information.

- The system will prompt you to confirm the changes. Click “Yes” to proceed.

- Verify the Coding:

- After saving, read the adaptation values again to ensure the new battery information has been correctly entered.

Troubleshooting Common Issues

- Incorrect Values: If you enter incorrect values, VCDS will display an error message. Double-check the information from the battery label and try again.

- Communication Errors: If VCDS cannot connect to the Battery Regulation module, ensure the cable is properly connected and the ignition is turned on.

- Unsupported Functions: Some older vehicles may not support battery coding via VCDS. In such cases, consult a professional technician.

Seeking Professional Assistance

If you encounter any difficulties during the VCDS battery coding process, CAR-CODING.EDU.VN offers professional remote support to guide you through each step. Our experts can help you troubleshoot issues, verify the coding, and ensure the battery is correctly registered with the vehicle’s BMS.

4. Common Mistakes to Avoid During Battery Coding

When performing battery coding, avoiding common mistakes is crucial to ensure the process is successful and doesn’t lead to further issues. Here are some mistakes to avoid:

Using Incorrect Battery Information

One of the most common mistakes is entering incorrect information from the battery label. This can lead to the vehicle’s Battery Management System (BMS) mismanaging the charging cycles, reducing battery life and causing electrical issues.

- Double-Check the Information: Always double-check the part number, vendor code, and serial number from the battery label before entering them into VCDS.

- Verify the Values: After entering the values, read the adaptation values again to ensure they have been correctly saved.

Ignoring Battery Specifications

Ignoring the battery specifications, such as the Ah rating and battery type (AGM, EFB), can lead to improper charging and reduced performance.

- Match the Specifications: Ensure the new battery’s specifications match the original battery or the vehicle’s requirements.

- Use the Correct Battery Type: If the vehicle originally used an AGM battery, replace it with another AGM battery and code it accordingly.

Failing to Follow the Correct Procedure

Skipping steps or not following the correct procedure can result in incomplete coding or errors.

- Follow the Steps: Adhere to the step-by-step guide provided in VCDS or consult a professional for guidance.

- Avoid Shortcuts: Do not skip any steps or try to take shortcuts, as this can lead to errors.

Using Incompatible Tools

Using non-genuine or incompatible VCDS cables and software can cause communication errors and lead to incorrect coding.

- Use Genuine Tools: Always use a genuine Ross-Tech VCDS interface cable and the latest version of the VCDS software.

- Check Compatibility: Ensure the VCDS software is compatible with your vehicle’s model and year.

Interrupting the Coding Process

Interrupting the coding process, such as disconnecting the cable or turning off the ignition, can cause data corruption and lead to ECU issues.

- Maintain a Stable Connection: Ensure the laptop has a stable internet connection and sufficient battery life.

- Avoid Interruptions: Do not disconnect the cable or turn off the ignition during the coding process.

Ignoring Error Messages

Ignoring error messages displayed by VCDS can lead to unresolved issues and potential damage.

- Read Error Messages: Pay attention to any error messages displayed by VCDS and troubleshoot the issue before proceeding.

- Consult a Professional: If you are unsure about an error message, consult a professional technician or CAR-CODING.EDU.VN for assistance.

Overlooking Firmware Updates

Failing to update the VCDS software and firmware can result in compatibility issues and errors.

- Keep Software Updated: Regularly update the VCDS software to the latest version.

- Update Firmware: Ensure the VCDS interface cable has the latest firmware installed.

By avoiding these common mistakes, you can ensure a smooth and successful battery coding process. If you encounter any difficulties or are unsure about any step, CAR-CODING.EDU.VN offers professional remote support to guide you through the process and ensure the battery is correctly registered with the vehicle’s BMS.

VCDS Interface

VCDS Interface

Example of a VCDS interface connected to a vehicle for diagnostic and coding purposes.

5. When to Seek Professional Remote Assistance

While VCDS battery coding can be performed independently, certain situations warrant seeking professional remote assistance from experts like CAR-CODING.EDU.VN.

Complex or Unclear Battery Information

If the battery label lacks a clear BEM code or the numbers don’t match VCDS requirements, professional assistance can help decode the battery information and determine the correct coding parameters.

Unfamiliarity with VCDS Software

If you are not familiar with VCDS software or have limited experience with vehicle diagnostics, seeking professional guidance can prevent errors and potential damage to the vehicle’s ECU.

Troubleshooting Difficult Issues

If you encounter issues during the coding process, such as communication errors or incorrect values, professional assistance can help troubleshoot the problem and ensure the battery is correctly registered with the vehicle’s BMS.

High-Value or Complex Vehicles

For high-value or complex vehicles with advanced electrical systems, it’s best to seek professional assistance to avoid potential issues that could result in costly repairs.

Lack of Confidence

If you lack confidence in your ability to perform the coding process correctly, seeking professional assistance can provide peace of mind and ensure the job is done right.

Time Constraints

If you have limited time or need the battery coded quickly, professional remote assistance can expedite the process and minimize downtime.

Warranty Concerns

If you are concerned about voiding the vehicle’s warranty, seeking professional assistance can ensure the coding is performed according to the manufacturer’s specifications.

CAR-CODING.EDU.VN offers expert remote support to guide you through each step of the VCDS battery coding process. Our experts can help you troubleshoot issues, verify the coding, and ensure the battery is correctly registered with the vehicle’s BMS. Contact us at +1 (641) 206-8880 or visit CAR-CODING.EDU.VN for assistance.

6. The Benefits of Using CAR-CODING.EDU.VN for Remote Assistance

Choosing CAR-CODING.EDU.VN for your remote VCDS battery coding needs offers several advantages over traditional methods or attempting the process independently.

Expertise and Experience

CAR-CODING.EDU.VN has a team of experienced professionals who specialize in VCDS coding and vehicle diagnostics. Our experts have in-depth knowledge of various vehicle makes and models, ensuring accurate and reliable coding.

Remote Convenience

Our remote assistance service allows you to have your battery coded from the comfort of your own garage or workshop. No need to travel to a dealership or specialized shop.

Cost-Effectiveness

Remote assistance is often more cost-effective than traditional methods, as it eliminates the need for expensive equipment or travel costs.

Time Savings

Our experts can quickly and efficiently code your battery, minimizing downtime and allowing you to get back on the road faster.

Error Prevention

By seeking professional assistance, you can avoid common mistakes that can lead to issues with the vehicle’s electrical system.

Support and Guidance

Our team provides comprehensive support and guidance throughout the coding process, answering any questions and addressing any concerns you may have.

Warranty Protection

Our coding services are performed according to the manufacturer’s specifications, ensuring your vehicle’s warranty remains intact.

CAR-CODING.EDU.VN is committed to providing high-quality remote VCDS battery coding services that are accurate, reliable, and cost-effective. Contact us today to learn more about how we can assist you with your battery coding needs. Our office is located at 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States. You can reach us via Whatsapp at +1 (641) 206-8880 or visit our website at CAR-CODING.EDU.VN.

7. Detailed Explanation: CAN Bus, MOST, FlexRay, and DoIP

Modern vehicles rely on sophisticated communication networks to facilitate the exchange of data between various electronic control units (ECUs). Understanding these networks is essential for effective VCDS battery coding and troubleshooting. Here’s an overview of the key communication protocols used in modern vehicles:

CAN Bus (Controller Area Network)

The CAN bus is a robust and widely used communication protocol that allows ECUs to communicate with each other without a central host computer. It was originally developed by Bosch in the 1980s and has become a standard in the automotive industry.

- Key Features:

- High Reliability: CAN bus is designed to operate in harsh automotive environments, with built-in error detection and correction mechanisms.

- Real-Time Communication: CAN bus provides real-time communication capabilities, ensuring timely data exchange between ECUs.

- Cost-Effective: CAN bus is relatively inexpensive to implement, making it a popular choice for automotive applications.

- Applications:

- Engine management systems

- Transmission control systems

- Anti-lock braking systems (ABS)

- Airbag control systems

- Body control modules (BCM)

MOST (Media Oriented Systems Transport)

MOST is a high-speed multimedia network used for transmitting audio, video, and data between ECUs in the vehicle. It is commonly used in infotainment systems, audio amplifiers, and rear-seat entertainment systems.

- Key Features:

- High Bandwidth: MOST provides high bandwidth capabilities, allowing for the transmission of large amounts of multimedia data.

- Real-Time Communication: MOST offers real-time communication capabilities, ensuring seamless audio and video playback.

- Flexible Topology: MOST supports various network topologies, allowing for flexible system designs.

- Applications:

- Infotainment systems

- Audio amplifiers

- Rear-seat entertainment systems

- Navigation systems

FlexRay

FlexRay is a high-speed, fault-tolerant communication protocol designed for safety-critical applications in vehicles. It provides deterministic communication, ensuring data is transmitted and received within a specific timeframe.

- Key Features:

- High Speed: FlexRay offers high-speed communication capabilities, allowing for the transmission of large amounts of data in a short amount of time.

- Fault Tolerance: FlexRay is designed to be fault-tolerant, ensuring continued operation even in the event of a component failure.

- Deterministic Communication: FlexRay provides deterministic communication, ensuring data is transmitted and received within a specific timeframe.

- Applications:

- Steering systems

- Braking systems

- Suspension systems

- Advanced driver-assistance systems (ADAS)

DoIP (Diagnostics over Internet Protocol)

DoIP is a diagnostic protocol that allows diagnostic tools to communicate with ECUs in the vehicle over the internet. It is used for remote diagnostics, software updates, and coding.

- Key Features:

- Remote Access: DoIP enables remote access to vehicle ECUs, allowing for diagnostics and coding from anywhere in the world.

- High Speed: DoIP provides high-speed communication capabilities, allowing for the transmission of large amounts of diagnostic data.

- Security: DoIP incorporates security measures to protect against unauthorized access to vehicle ECUs.

- Applications:

- Remote diagnostics

- Software updates

- Coding and programming

- Vehicle monitoring

Understanding these communication protocols is essential for effective VCDS battery coding and troubleshooting. CAR-CODING.EDU.VN offers expert remote support to guide you through each step of the coding process and ensure the battery is correctly registered with the vehicle’s BMS. Contact us at +1 (641) 206-8880 or visit CAR-CODING.EDU.VN for assistance.

8. Safety Precautions During VCDS Battery Coding

Safety should always be a top priority when performing VCDS battery coding. Here are some essential safety precautions to keep in mind:

Working in a Well-Ventilated Area

When working with car batteries, ensure you are in a well-ventilated area to avoid inhaling harmful gases, such as hydrogen.

Wearing Protective Gear

Wear safety glasses and gloves to protect your eyes and skin from battery acid and other hazardous materials.

Disconnecting the Battery Properly

When disconnecting the battery, follow the manufacturer’s instructions carefully. Typically, you should disconnect the negative terminal first, followed by the positive terminal.

Avoiding Sparks

Avoid creating sparks near the battery, as this could ignite the hydrogen gas and cause an explosion.

Using Insulated Tools

Use insulated tools to prevent accidental short circuits when working with the battery terminals.

Proper Disposal of Old Batteries

Dispose of old batteries properly at a designated recycling center to prevent environmental contamination.

Consulting a Professional

If you are unsure about any step of the battery coding process, consult a professional technician or CAR-CODING.EDU.VN for assistance.

By following these safety precautions, you can minimize the risk of accidents and injuries during VCDS battery coding.

9. Example Cases: Successful VCDS Battery Coding with Remote Support

To illustrate the effectiveness and benefits of remote assistance in VCDS battery coding, here are a few example cases where CAR-CODING.EDU.VN successfully assisted technicians:

Case 1: Coding an AGM Battery on an Audi A6

A technician was replacing the battery on an Audi A6 but was unsure of the correct VCDS coding parameters for the new AGM battery. CAR-CODING.EDU.VN provided remote assistance, guiding the technician through the coding process and ensuring the battery was correctly registered with the vehicle’s BMS.

Case 2: Troubleshooting Communication Errors on a VW Golf

A technician encountered communication errors when attempting to code a new battery on a VW Golf. CAR-CODING.EDU.VN remotely diagnosed the issue and provided a solution, allowing the technician to successfully code the battery.

Case 3: Coding a Battery Without a BEM Code on a BMW 5 Series

A technician was replacing the battery on a BMW 5 Series, but the new battery did not have a BEM code. CAR-CODING.EDU.VN provided remote assistance, helping the technician manually enter the correct battery information and successfully code the battery.

Case 4: Solving Battery Drain Issues on a Mercedes-Benz C-Class

A technician was dealing with a Mercedes-Benz C-Class that had persistent battery drain issues after a battery replacement. CAR-CODING.EDU.VN assisted by remotely checking the coding and adaptation settings, identifying a misconfiguration that was causing the drain. Correcting the coding resolved the issue and prevented further battery drain.

Case 5: Coding a High-Capacity Battery on a Land Rover Range Rover

A technician was upgrading the battery on a Land Rover Range Rover to a higher-capacity model for enhanced performance. CAR-CODING.EDU.VN provided remote support to ensure the vehicle’s charging system was properly configured for the new battery, optimizing its performance and lifespan.

These examples demonstrate the value of remote assistance in VCDS battery coding. CAR-CODING.EDU.VN offers expert support to guide you through each step of the coding process and ensure the battery is correctly registered with the vehicle’s BMS. Contact us at +1 (641) 206-8880 or visit CAR-CODING.EDU.VN for assistance.

Coding in Progress

Coding in Progress

Remote coding in progress, facilitated by CAR-CODING.EDU.VN experts

10. Frequently Asked Questions (FAQ) About VCDS Battery Coding

Q1: Is it safe to perform VCDS battery coding myself?

Yes, if you have the necessary knowledge, tools, and follow the correct procedures. However, if you are unsure or lack experience, it’s best to seek professional assistance to avoid potential issues.

Q2: What is the process for remote assistance with CAR-CODING.EDU.VN?

The process involves connecting your laptop to the vehicle’s OBD-II port, launching VCDS software, and granting remote access to our experts. Our team will guide you through the coding process and ensure the battery is correctly registered.

Q3: How much does remote VCDS battery coding cost?

The cost of remote VCDS battery coding varies depending on the vehicle make, model, and complexity of the coding process. Contact CAR-CODING.EDU.VN for a personalized quote.

Q4: What types of vehicles and batteries are supported?

CAR-CODING.EDU.VN supports a wide range of vehicle makes and models, including Audi, VW, BMW, Mercedes-Benz, and more. We also support various battery types, including lead-acid, AGM, and EFB batteries.

Q5: What equipment is required on my end for remote assistance?

You will need a laptop with a stable internet connection, a genuine Ross-Tech VCDS interface cable, and the VCDS software installed on your laptop.

Q6: How long does the remote battery coding process take?

The duration of the remote battery coding process varies depending on the vehicle and complexity of the coding. In most cases, it can be completed within 30-60 minutes.

Q7: What if I encounter issues during the coding process?

CAR-CODING.EDU.VN provides comprehensive support and guidance throughout the coding process. Our experts can troubleshoot issues and ensure the battery is correctly registered with the vehicle’s BMS.

Q8: Will coding a new battery void my vehicle’s warranty?

No, coding a new battery according to the manufacturer’s specifications should not void your vehicle’s warranty. However, it’s essential to follow the correct procedures and use genuine tools to avoid potential issues.

Q9: What happens if the coding is not done correctly?

Incorrect coding can lead to reduced battery life, charging problems, electrical issues, and warning lights. It’s essential to ensure the coding is performed correctly or seek professional assistance.

Q10: How can I schedule remote assistance with CAR-CODING.EDU.VN?

You can schedule remote assistance by contacting us at +1 (641) 206-8880 or visiting our website at CAR-CODING.EDU.VN. Our team will assist you in scheduling a convenient time for the coding process.

CAR-CODING.EDU.VN is your trusted partner for remote VCDS battery coding. Contact us today for expert assistance and ensure your vehicle’s electrical system is functioning optimally. Our office is located at 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States. You can reach us via Whatsapp at +1 (641) 206-8880 or visit our website at CAR-CODING.EDU.VN.

Don’t let battery coding challenges slow you down. Contact CAR-CODING.EDU.VN now for immediate remote support and keep your customers’ vehicles running smoothly. Our expert team is ready to assist you with VCDS battery coding, ECU programming, and hidden feature activation. Reach out via Whatsapp at +1 (641) 206-8880 or visit CAR-CODING.EDU.VN for reliable automotive coding solutions.