Are you struggling to interpret Lambda values in your VCDS logs and prefer to see Air-Fuel Ratio (AFR) instead? Absolutely, it’s possible to convert Lambda values to AFR for easier understanding and analysis. At CAR-CODING.EDU.VN, we offer expert remote support to help you navigate car coding and diagnostics, including accurate interpretation of engine performance data. Need assistance with ECU programming, activating hidden features, or clearing fault codes? Contact us for prompt and reliable remote automotive coding support.

Contents

- 1. Understanding Lambda and AFR

- 1.1 Why Convert Lambda to AFR?

- 1.2 The Conversion Formula

- 2. Reading Lambda Values in VCDS

- 2.1 Identifying Lambda Parameters

- 2.2 Interpreting Lambda Readings

- 3. Converting Lambda to AFR in VCDS Logs

- 3.1 Exporting VCDS Logs

- 3.2 Converting Lambda to AFR in a Spreadsheet

- 4. Analyzing AFR for Performance Tuning

- 4.1 Naturally Aspirated Engines

- 4.2 Turbocharged Engines

- 4.3 Common Issues Indicated by AFR

- 5. VCDS Logging: A Step-by-Step Guide

- 5.1 Getting Started

- 5.2 Checking for Fault Codes

- 5.3 Setting Up Logging

- 5.4 Initiating and Capturing Logs

- 6. Advanced Logging Parameters

- 6.1 Misfires

- 6.2 Lambda/Air:Fuel/EGT

- 7. Understanding Logged Data

- 7.1 Accelerator Position

- 7.2 Engine Speed

- 7.3 Charge Air Pressure (Specified Value)

- 7.4 Intake Manifold Pressure (Absolute)

- 7.5 Air Mass

- 7.6 Intake Air Temperature

- 7.7 Ignition Angle (Actual)

- 7.8 ING_AD_KNK_x

- 7.9 RFP_AV

- 8. The Importance of Professional Assistance

- 9. Common Car Coding and Programming Tasks

- 9.1 ECU Programming

- 9.2 Variant Coding

- 9.3 Activating Hidden Features

- 9.4 Clearing Fault Codes

- 10. Why Choose CAR-CODING.EDU.VN?

- 11. Understanding Key Terminology

- 11.1 ECU (Engine Control Unit)

- 11.2 VIN Coding

- 11.3 Variant Coding

- 11.4 Flashing

- 11.5 CAN Bus

- 11.6 MOST

- 11.7 FlexRay

- 11.8 DoIP

- 12. Example Coding Scenarios and Success Stories

- 12.1 Activating Cornering Lights on an Audi A4

- 12.2 Clearing Airbag Fault Code on a Volkswagen Golf

- 12.3 Optimizing Performance on a BMW 3 Series

- 13. Latest Updates in Car Coding Technology

- 13.1 Support for New Vehicle Models

- 13.2 Advanced Driver-Assistance Systems (ADAS) Calibration

- 13.3 Cybersecurity Measures

- 14. Frequently Asked Questions (FAQ)

- 14.1 Is Car Coding Safe?

- 14.2 What is the Remote Support Process?

- 14.3 How Much Does Car Coding Cost?

- 14.4 What Types of Vehicles and Features Do You Support?

- 14.5 What Equipment Do I Need?

- 15. Call to Action

1. Understanding Lambda and AFR

Lambda (λ) represents the ratio of actual air-fuel ratio to the stoichiometric air-fuel ratio. A Lambda value of 1 indicates a stoichiometric mixture, where there is a perfect balance of air and fuel for complete combustion. Values less than 1 indicate a rich mixture (more fuel), while values greater than 1 indicate a lean mixture (more air).

Air-Fuel Ratio (AFR) expresses the ratio of air mass to fuel mass in the combustion process. For gasoline engines, the stoichiometric AFR is typically around 14.7:1.

1.1 Why Convert Lambda to AFR?

While Lambda is a useful metric, many technicians and tuners find AFR more intuitive and easier to work with. Converting Lambda to AFR provides a more direct understanding of the air-fuel mixture’s richness or leanness.

1.2 The Conversion Formula

To convert Lambda to AFR, simply multiply the Lambda value by the stoichiometric AFR of the fuel being used:

AFR = Lambda * Stoichiometric AFR

For gasoline, use 14.7:1 as the stoichiometric AFR:

AFR = Lambda * 14.7

For example, if Lambda is 0.9, then AFR = 0.9 * 14.7 = 13.23

This image illustrates a table converting Lambda values to corresponding Air-Fuel Ratio (AFR) values, aiding in understanding engine fuel mixture.

2. Reading Lambda Values in VCDS

VCDS (VAG-COM Diagnostic System) is a powerful tool for diagnosing and logging data from Volkswagen, Audi, Skoda, and SEAT vehicles. It provides access to various engine control module (ECU) parameters, including Lambda values.

2.1 Identifying Lambda Parameters

In VCDS, Lambda values are typically found in the engine control module (01-Engine). Look for parameters such as:

- Lambda probe actual; bank 1

- Lambda probe actual; bank 2

- Lambda probes specification; bank 1

- Lambda probes specification; bank 2

These parameters indicate the actual and specified Lambda values for each bank of the engine.

2.2 Interpreting Lambda Readings

- Lambda = 1: Stoichiometric mixture (ideal for cruising and low-load conditions)

- Lambda < 1: Rich mixture (used during acceleration and high-load conditions to prevent knocking and provide maximum power)

- Lambda > 1: Lean mixture (used during idle and light-load conditions to improve fuel efficiency)

3. Converting Lambda to AFR in VCDS Logs

While VCDS does not directly display AFR, you can easily convert the logged Lambda values to AFR using a spreadsheet program like Microsoft Excel or Google Sheets.

3.1 Exporting VCDS Logs

- Perform a VCDS log, including the desired Lambda parameters.

- Save the log file in CSV format.

3.2 Converting Lambda to AFR in a Spreadsheet

- Open the CSV file in your spreadsheet program.

- Create a new column for AFR.

- Enter the formula to convert Lambda to AFR. For example, if the Lambda values are in column C, enter the following formula in the AFR column:

=C2*14.7(assuming gasoline fuel). - Drag the formula down to apply it to all rows in the log.

- You now have a column displaying AFR values for each data point in the log.

4. Analyzing AFR for Performance Tuning

Monitoring AFR is crucial for ensuring optimal engine performance and preventing damage. Here are some guidelines for AFR targets during different operating conditions:

4.1 Naturally Aspirated Engines

- Idle: 14.5-15.5:1

- Cruise: 14.0-15.0:1

- Wide Open Throttle (WOT): 12.5-13.5:1

4.2 Turbocharged Engines

- Idle: 14.5-15.5:1

- Cruise: 14.0-15.0:1

- Wide Open Throttle (WOT): 11.5-12.5:1

4.3 Common Issues Indicated by AFR

- Lean AFR (too high): Can cause overheating, knocking, and engine damage. Possible causes include vacuum leaks, faulty fuel injectors, or a weak fuel pump.

- Rich AFR (too low): Can cause poor fuel economy, reduced power, and increased emissions. Possible causes include a faulty mass airflow (MAF) sensor, leaking fuel injectors, or a malfunctioning oxygen sensor.

5. VCDS Logging: A Step-by-Step Guide

To effectively diagnose your vehicle’s performance, accurate logging with VCDS is essential. This guide provides a detailed walkthrough to help you capture and interpret critical data.

5.1 Getting Started

- Connect the VCDS Cable: Plug the Ross-Tech VCDS cable into the OBDII port located under the dashboard on the driver’s side.

- Launch VCDS Software: Turn the car’s ignition to the “ON” position (or start the engine) and launch the VCDS software on your Windows computer.

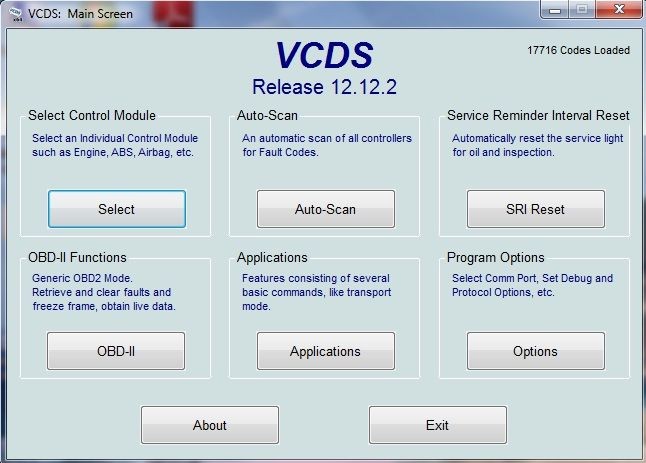

VCDS Main Menu

VCDS Main Menu

This image shows the main menu of the VCDS software, highlighting the “Auto-Scan” and “Select” buttons.

5.2 Checking for Fault Codes

- Run Auto-Scan: Before logging, ensure there are no existing fault codes. Click the “Auto-Scan” button on the VCDS main menu.

- Start the Scan: In the Auto-Scan section, click “Start” to begin scanning all modules. This process may take a few minutes.

- Review and Clear Faults: If any faults are found, save the scan results (copy/paste, save, or print). Then, clear the faults by clicking the “Clear all DTC’s” button. After clearing, “Close” the Auto-Scan section to return to the main menu.

This image displays the VCDS Auto-Scan interface, showing the progress of the scan and options to start, stop, and clear DTCs.

5.3 Setting Up Logging

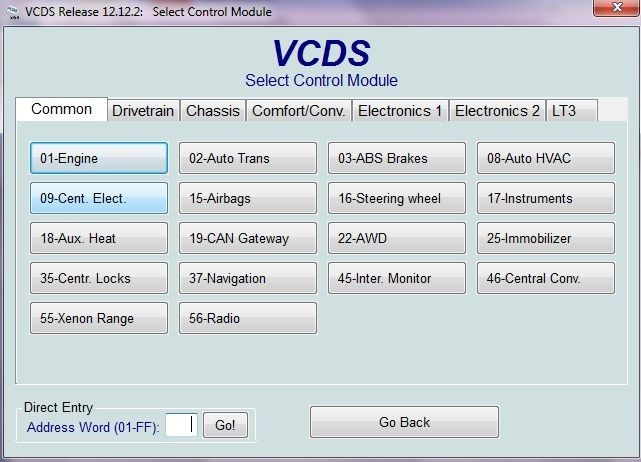

- Select Control Module: From the main menu, click the “Select” button under “Select Control Module.”

- Choose Engine Module: In the “Common” tab, click the “01-Engine” module button.

VCDS Module Selection

VCDS Module Selection

This image shows the VCDS module selection screen with the “01-Engine” module highlighted.

- Access Advanced Measuring Values: In the Engine Controller module, click the “Adv. Meas. Values” button to access the logging section.

This image displays the VCDS Engine Controller module interface, with the “Adv. Meas. Values” button indicated.

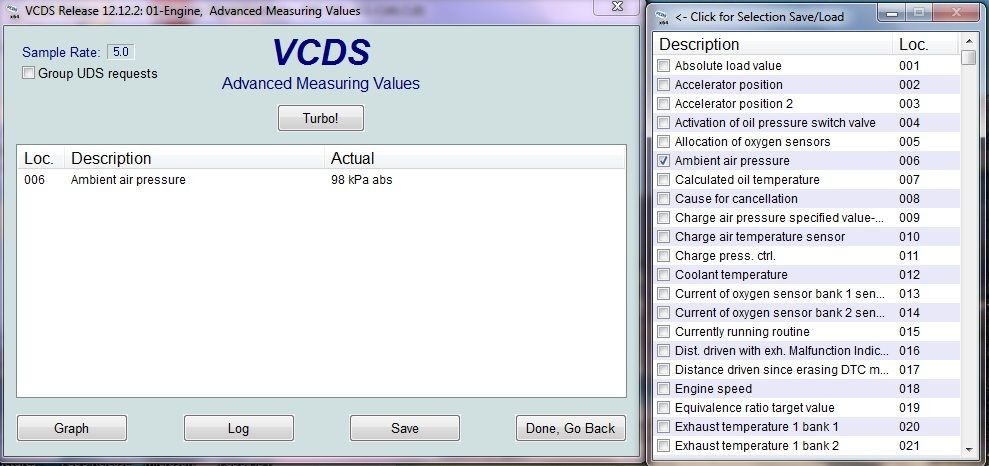

- Record Ambient Air Pressure: Select “Ambient Air Pressure” from the parameter list. Note the displayed value for later boost calculations, then uncheck the box.

VCDS Ambient Air Pressure

VCDS Ambient Air Pressure

This image illustrates selecting the “Ambient Air Pressure” parameter in VCDS and recording its value.

-

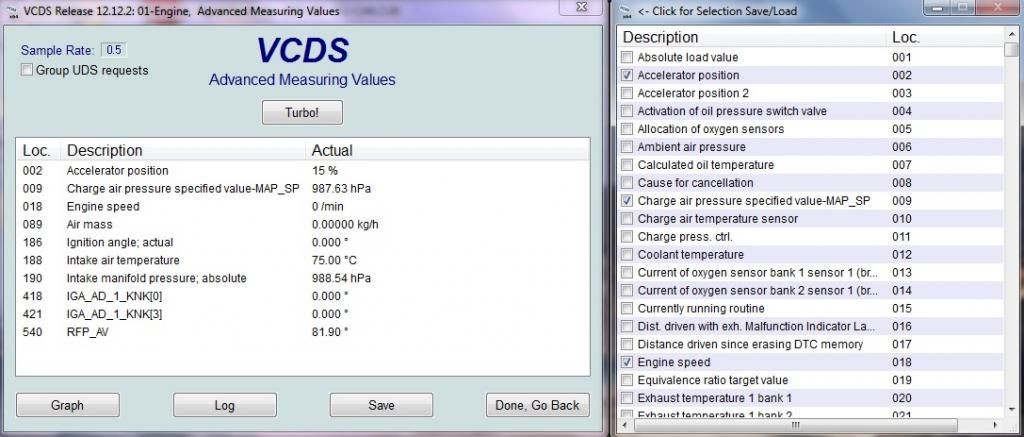

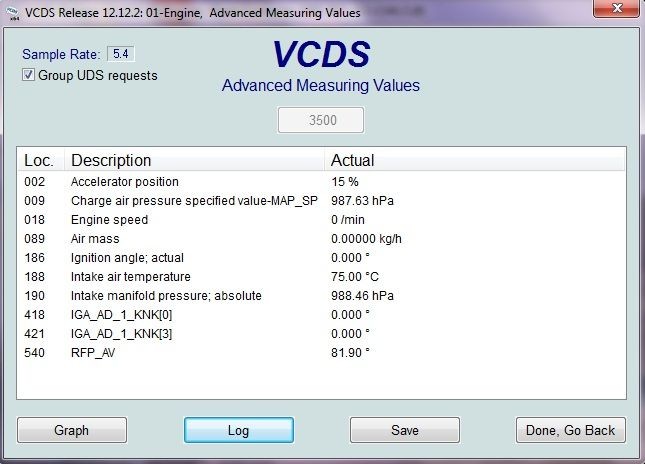

Select Parameters to Log: Choose the parameters you want to log from the list. VCDS allows a maximum of 12 parameters, or 10 if using grouping. Focus on the most important parameters for your logging session to maximize resolution. Recommended parameters for general performance logging include:

- 002 – Accelerator position – in %

- 009 – Charge air pressure specified value – in hPa (specified boost + ambient air pressure)

- 018 – Engine speed – in RPM

- 089 – Air mass – in kg/h (intake)

- 186 – Ignition angle; actual – in degrees

- 188 – Intake air temperature – in degrees C

- 190 – Intake manifold pressure; absolute – in hPa (actual boost + ambient air pressure)

- 418-423 – IGA_AD_KNK[0-5] – in degrees (knock detection/timing pulled on cylinders 1-6) – select two cylinders

- 540 – RFP_AV – bypass valve percentage

-

Save Parameter List: Click the “VCDS” icon in the top-left corner and save the parameter list for easy access later. Name the file descriptively (e.g., “performance”).

VCDS Logging Fields

VCDS Logging Fields

This image shows the VCDS logging fields selection, emphasizing the importance of choosing relevant parameters.

This image demonstrates saving the selected logging fields in VCDS for future use.

5.4 Initiating and Capturing Logs

- Enable Group UDS Requests: Click the “Turbo” button and check the “Group UDS requests” box. This speeds up logging and ensures all fields have the same timestamp, crucial for accurate analysis.

- Start Logging Session: Click the “Log” button to initiate the logging session but not start the actual logging.

VCDS Logging Interface

VCDS Logging Interface

This image highlights the “Turbo” button and “Group UDS requests” checkbox in the VCDS logging interface.

- Begin Data Capture: With the engine running, click the “Start” button to begin the actual logging process.

- Perform Logging Run: Conduct the logging run in a safe, controlled environment, aiming for a full 3rd or 4th gear pull (approximately 3000 RPM to 7000 RPM). Ensure the A/C and radio are OFF, windows are UP, car is in dynamic mode (if available), and traction/ASR is OFF (hold traction button for at least 5 seconds). Log on a flat surface and, if possible, repeat runs in similar conditions for accurate data comparison.

- Stop Logging: Once you’ve captured the necessary logs, click the “Stop” button to halt the logging process. Then, click “Done, close.”

- Locate Log File: The logs will be saved as a .CSV file in the Ross-Tech/VCDS/Logs folder (typically on the C:/ drive or the drive where the Ross-Tech software is installed). Open the file with Excel or a similar spreadsheet program.

This image shows the VCDS logging start screen with the “Start” button ready to initiate data capture.

This image demonstrates the VCDS logging stop screen with the “Stop” and “Done, close” buttons highlighted.

6. Advanced Logging Parameters

VCDS offers a wide array of parameters beyond the basics. Here are some additional parameters to consider for more in-depth diagnostics:

6.1 Misfires

If you’re experiencing misfires, log misfires on all cylinders to pinpoint the issue:

- 251 – Misfires all cylinders per 1000 rpm

- 253 – Misfires cylinder 1 per 1000 rpm

- 255 – Misfires cylinder 2 per 1000 rpm

- 257 – Misfires cylinder 3 per 1000 rpm

- 259 – Misfires cylinder 4 per 1000 rpm

- 261 – Misfires cylinder 5 per 1000 rpm

- 263 – Misfires cylinder 6 per 1000 rpm

6.2 Lambda/Air:Fuel/EGT

For detailed fueling analysis, log Lambda values, along with exhaust gas temperature (EGT):

- 020 – Exhaust temperature 1 bank 1

- 021 – Exhaust temperature 1 bank 2

- 238 – Lambda probes actual; bank1

- 239 – Lambda probes actual; bank2

- 244 – Lambda probes specification; bank 1

- 245 – Lambda probes specification; bank 2

- 246 – Lambda probes specified; bank1

- 247 – Lambda probes specified; bank2

7. Understanding Logged Data

Interpreting logged data is crucial for diagnosing performance issues. Here’s a breakdown of key parameters:

7.1 Accelerator Position

Indicates the throttle position. Wide-open throttle (WOT) is typically in the 93-95% range.

7.2 Engine Speed

Provides a reference point for when the engine is at maximum performance, usually between 3000-7000 RPM.

7.3 Charge Air Pressure (Specified Value)

Represents the ECU’s requested boost pressure. Convert this value from hPa to PSI and subtract ambient air pressure to determine the actual requested boost:

Requested boost = (Charge air pressure; specified value hPa) - (Ambient air pressure kPa x 10) x 0.014503774

7.4 Intake Manifold Pressure (Absolute)

Indicates the actual pressure in the intake manifold. Convert this value from hPa to PSI and subtract ambient pressure to determine the actual boost:

Actual boost = (Intake manifold pressure; absolute hPa) – (Ambient air pressure kPa x 10) x 0.014503774

7.5 Air Mass

Represents the amount of air entering the engine. Higher values generally indicate better performance.

7.6 Intake Air Temperature

Indicates the temperature of the air entering the engine. Lower IATs are preferable for optimal performance.

7.7 Ignition Angle (Actual)

Represents the total actual timing.

7.8 ING_AD_KNK_x

Indicates the amount of timing pulled from a specific cylinder due to knock detection.

7.9 RFP_AV

Represents the bypass valve opening percentage. A properly tuned car should ideally show 0%.

8. The Importance of Professional Assistance

While VCDS logging and data analysis can provide valuable insights into your vehicle’s performance, interpreting the data and making appropriate adjustments can be complex. Incorrect modifications can lead to serious engine damage.

CAR-CODING.EDU.VN offers professional remote car coding and diagnostic services to help you get the most out of your vehicle safely and effectively. Our experienced technicians can:

- Analyze your VCDS logs and identify potential issues.

- Provide expert advice on tuning and modifications.

- Perform remote coding and programming to optimize your vehicle’s performance.

- Activate hidden features and customize your car to your preferences.

9. Common Car Coding and Programming Tasks

CAR-CODING.EDU.VN specializes in a wide range of car coding and programming tasks, including:

9.1 ECU Programming

Updating or modifying the software on your vehicle’s engine control unit (ECU) to improve performance, fuel efficiency, or drivability.

9.2 Variant Coding

Adjusting vehicle settings to match specific equipment or regional requirements.

9.3 Activating Hidden Features

Enabling features that are already built into your car but not activated from the factory, such as:

- Cornering lights

- Coming home/leaving home lights

- Gauge staging (needle sweep)

- Video in motion (VIM)

- Memory seats link to key

- Folding mirrors on lock

- Seatbelt warning deactivation

9.4 Clearing Fault Codes

Permanently removing fault codes and warning lights from your dashboard.

10. Why Choose CAR-CODING.EDU.VN?

- Expertise: Our technicians have extensive experience in car coding and programming for a wide range of makes and models.

- Remote Support: We provide convenient and efficient remote support, allowing you to get the help you need from the comfort of your own garage.

- Safety: We prioritize safety and ensure that all coding and programming is performed correctly to avoid damage to your vehicle.

- Affordability: Our services are competitively priced, offering excellent value for your money.

- Reliability: We are committed to providing prompt and reliable support to our customers.

11. Understanding Key Terminology

Navigating the world of car coding requires familiarity with specific terms. Here’s a glossary to help you understand the key concepts:

11.1 ECU (Engine Control Unit)

The ECU is the central computer in your car that controls the engine’s operation. It manages various functions such as fuel injection, ignition timing, and emissions control.

11.2 VIN Coding

VIN (Vehicle Identification Number) coding involves programming the ECU with the car’s unique VIN to ensure proper functionality and prevent theft.

11.3 Variant Coding

Variant coding adjusts the ECU’s settings to match the specific configuration of the vehicle, such as optional equipment or regional variations.

11.4 Flashing

Flashing refers to the process of overwriting the ECU’s existing software with a new version. This is often done to update the ECU with the latest software improvements or to install a performance tune.

11.5 CAN Bus

CAN (Controller Area Network) bus is a communication protocol used in modern vehicles to allow different electronic control units (ECUs) to communicate with each other.

11.6 MOST

MOST (Media Oriented Systems Transport) is a high-speed communication protocol used for multimedia and infotainment systems in vehicles.

11.7 FlexRay

FlexRay is a high-speed, fault-tolerant communication protocol used in advanced automotive applications such as electronic stability control (ESC) and adaptive cruise control (ACC).

11.8 DoIP

DoIP (Diagnostics over Internet Protocol) is a communication protocol used for remote diagnostics and programming of ECUs over the internet.

12. Example Coding Scenarios and Success Stories

At CAR-CODING.EDU.VN, we’ve assisted numerous clients with a wide range of coding and programming tasks. Here are a few examples:

12.1 Activating Cornering Lights on an Audi A4

A client wanted to activate the cornering lights on their Audi A4, which were not enabled from the factory. Using VCDS and our remote support, we were able to quickly and easily activate the cornering lights, improving visibility during nighttime driving.

12.2 Clearing Airbag Fault Code on a Volkswagen Golf

A client had an airbag fault code on their Volkswagen Golf that persisted even after replacing the faulty sensor. Our technicians remotely accessed the vehicle’s ECU and performed advanced coding to clear the fault code permanently.

12.3 Optimizing Performance on a BMW 3 Series

A client wanted to improve the performance of their BMW 3 Series. We analyzed their VCDS logs and recommended a custom ECU tune. After flashing the ECU with the new tune, the client reported a significant improvement in horsepower and torque.

13. Latest Updates in Car Coding Technology

The field of car coding is constantly evolving, with new features and capabilities being added to vehicles every year. CAR-CODING.EDU.VN stays up-to-date with the latest advancements in car coding technology to provide our clients with the most cutting-edge solutions.

13.1 Support for New Vehicle Models

We continuously expand our support for new vehicle models, ensuring that we can provide coding and programming services for the latest cars on the market.

13.2 Advanced Driver-Assistance Systems (ADAS) Calibration

Many new vehicles are equipped with ADAS features such as lane departure warning, adaptive cruise control, and automatic emergency braking. These systems require precise calibration after any repairs or modifications. CAR-CODING.EDU.VN offers ADAS calibration services to ensure that these systems function correctly and safely.

13.3 Cybersecurity Measures

As vehicles become more connected, cybersecurity is becoming increasingly important. We implement the latest cybersecurity measures to protect your vehicle from hacking and unauthorized access.

14. Frequently Asked Questions (FAQ)

14.1 Is Car Coding Safe?

When performed correctly by experienced professionals, car coding is generally safe. However, incorrect coding can lead to serious problems, including engine damage or electrical malfunctions. It’s essential to use the correct tools and procedures and to have a thorough understanding of the vehicle’s systems.

14.2 What is the Remote Support Process?

Our remote support process is simple and straightforward:

- Contact us to discuss your needs and schedule an appointment.

- Connect your VCDS cable to your vehicle and your computer.

- Download and install our remote access software.

- Grant our technician remote access to your computer.

- Our technician will perform the coding or programming tasks while you watch.

14.3 How Much Does Car Coding Cost?

The cost of car coding varies depending on the complexity of the task and the vehicle model. Contact us for a free quote.

14.4 What Types of Vehicles and Features Do You Support?

We support a wide range of makes and models, including Volkswagen, Audi, Skoda, SEAT, BMW, and more. We can code a variety of features, including:

- Performance enhancements

- Convenience features

- Safety features

- Cosmetic customizations

14.5 What Equipment Do I Need?

To receive remote car coding support, you will need:

- A Ross-Tech VCDS cable

- A Windows laptop with internet access

- Our remote access software

15. Call to Action

Don’t let complex coding challenges hold you back. Contact CAR-CODING.EDU.VN today for expert remote car coding support. Whether you need help interpreting VCDS logs, activating hidden features, or optimizing your vehicle’s performance, our experienced technicians are here to assist you.

Contact us now:

- Address: 100 Tech Innovation Dr, Suite 500, San Jose, CA 95110, United States

- WhatsApp: +1 (641) 206-8880

- Website: CAR-CODING.EDU.VN

Let CAR-CODING.EDU.VN unlock the full potential of your vehicle!